Latest Articles

A vital component of contemporary production, stainless steel is valued for its strength, resilience to corrosion, and longevity. 304 and 316L are two of the most widely utilized austenitic stainless steels among the many grades that are available.

Read More

In industries like aerospace, automotive, defense, and heavy machinery, metal forging is an essential manufacturing technique that creates high-strength components. Accurately estimating the cost of forging is crucial for manufacturers to remain competitive and ensure the profitability of their projects.

Read More

Casting is a foundational manufacturing process for producing metal parts with complex geometry in large volumes. Yet even experienced foundries frequently encounter defects that elevate scrap, rework, and cost.

Read More

Steel forging stands at the core of modern heavy-industry manufacturing. From automotive axles and turbine shafts to construction machinery and rail couplings, forged steel components define the strength, safety, and longevity of countless mechanical systems.

Read More

In industries where strength, longevity, and corrosion resistance are critical, stainless steel forgings are indispensable. However, careful attention to detail throughout the forging process is necessary to achieve these qualities. Component integrity can be jeopardized by even small flaws, particularly in corrosion-prone conditions.

Read More

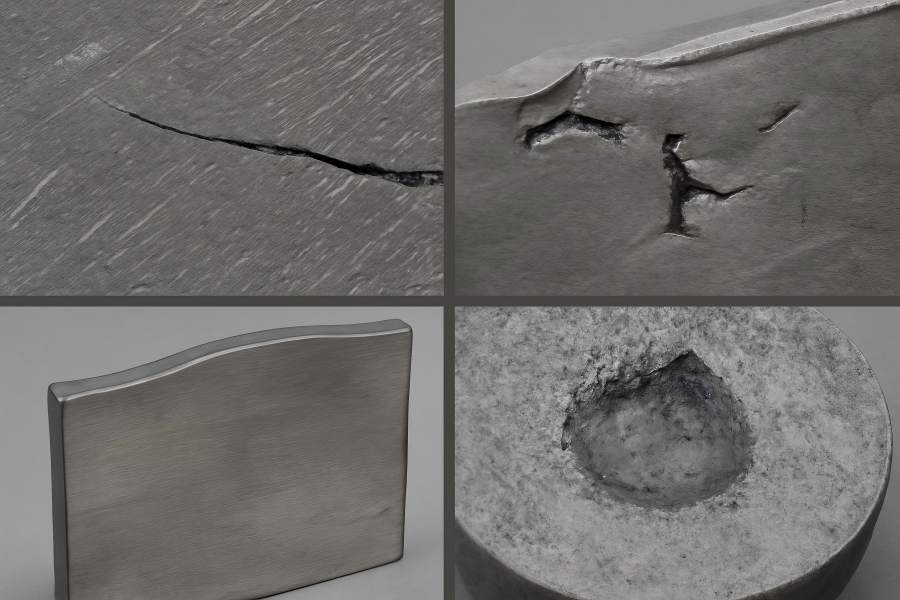

Forging shapes metals like steel, aluminum, and titanium into strong, durable parts using compressive forces. However, defects arising from temperature, pressure, material properties, or mold design can affect quality, increase rework, and raise costs. Improving product performance, cutting waste, and increasing efficiency all depend on fixing these flaws.

Read More

Estimating the costs for forging custom projects is essential for determining project feasibility, pricing, and profitability. Understanding the key components that make up the forging cost and utilizing the right methods and tools for calculation will help ensure accurate estimates and optimize the manufacturing process.

Read More

In modern engine design, choosing the right cylinder sleeve material is crucial for efficiency, durability, and heat management. As engines advance and propulsion technologies diversify, materials science continues to meet growing demands.

Read More

Selecting between carbon steel, stainless steel, and alloy flanges can significantly affect a system’s performance, longevity, and overall cost. Each material has its own characteristics—ranging from corrosion resistance and tensile strength to thermal stability and machinability—that make it more or less suitable for specific operating environments.

Read More

In the competitive world of manufacturing, the right hot forging supplier can make or break your project’s success. When selecting a partner, quality, consistency, engineering support, and long-term dependability are more important considerations than pricing alone.

Read More

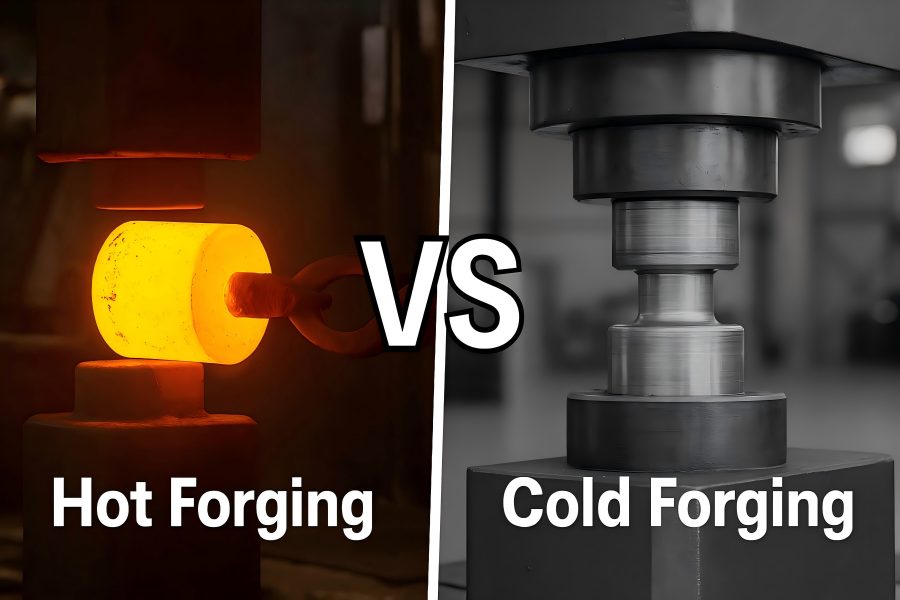

In the world of metal forming, forging remains one of the most trusted processes for producing high-strength, durable, and reliable components. However, not all forging is the same. The two primary methods—hot forging and cold forging—differ not only in temperature but also in their influence on part quality, production economics, and long-term performance.

Read More

In industrial manufacturing, hot forging is one of the most reliable and cost-effective methods for producing strong, durable, and high-performance metal parts. From automotive crankshafts and turbine blades to heavy-duty gears and hydraulic components, forged parts dominate industries where safety, fatigue strength, and dimensional consistency are critical.

Read More