Forged Gears

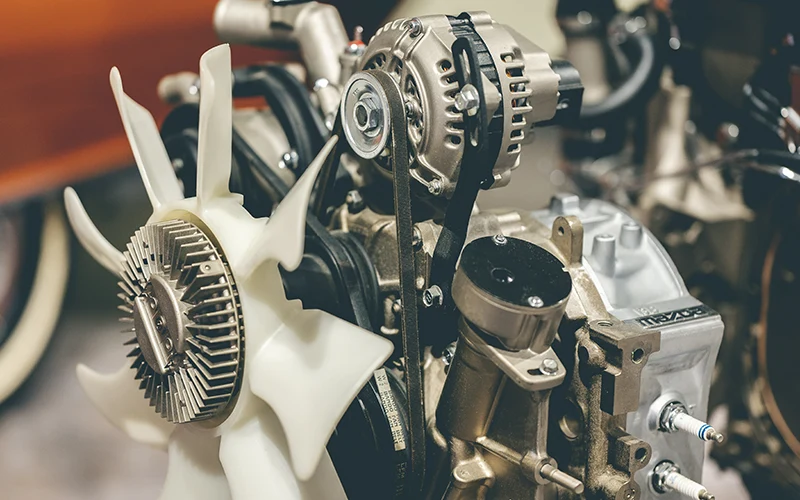

- We manufacture custom-forged gear blanks and wheels using flexible material options, supporting low-volume production and minimizing final machining costs.

- Available in various shapes, our forged gears deliver precision and durability for demanding applications in mining, drilling, cement, and high-pressure pumping systems.

- For Closed, Open, and Semi-open Transmissions

- Fits Parallel, Intersecting, and Staggered Shafts

- Spur, Helical, Bevel, Worm, and Torsoing Gear Types Available

- ISO9001, PED, SGS Certified for Quality

- Full Material and Test Documentation Provided

Based on Material

Carbon Steel Gears

Economical gears with good strength and machinability, ideal for general-purpose applications requiring moderate wear resistance and reliable performance.

Stainless Steel Gears

Corrosion-resistant gears suited for food, medical, and marine environments, offering durability, hygiene, and consistent performance in harsh or wet conditions.

Alloy Steel Gears

Enhanced strength, toughness, and heat resistance make these gears ideal for automotive, industrial, and high-load applications with extended service life.

Nickel Alloys Gears

High-performance gears offering exceptional corrosion, heat, and fatigue resistance, perfect for aerospace, power generation, and chemical processing environments.

Based on Gear Shape

For a variety of transmission applications, forged gears come in spur, helical, bevel, worm, hypoid, internal, herringbone, crown, and rack shapes.

- Straight teeth; ideal for parallel shaft transmission with high efficiency.

- Simple design; quiet at low speed, noisier at high speed.

- Common in machines, conveyors, and gear pumps.

- Angled teeth for smooth, quiet operation with greater load capacity.

- Ideal for high-speed, high-power transmission in gearboxes.

- Support both parallel and crossed shaft connections.

- Cone-shaped gears for intersecting shafts at 90 degrees.

- Available in straight, spiral, and zerol tooth types.

- Found in differentials, marine drives, and power tools.

- Worm meshes with wheel for compact high-ratio reduction.

- Simple design; quiet at low speed, noisier at high speed.

- Common in machines, conveyors, and gear pumps.

- Offset bevel gears; shafts don’t intersect but are angled.

- Enable low shaft positions, ideal for vehicles.

- Strong, quiet, and require good lubrication.

- Teeth located inside the gear body for internal meshing.

- Extensively utilized in compact and planetary gear systems.

- High gear ratios in limited design space.

- V-shaped double helicals cancel axial thrust during operation.

- Ensures stable, quiet motion under heavy loads.

- Widely used in turbines, compressors, and large equipment.

- Teeth extend perpendicular to face for angular drives.

- Found in simple gear systems, toys, and clocks.

- Useful for right-angle transmission requirements.

- Pinion rotates along rack to create linear motion.

- Found in CNC, automation, and steering systems.

- Ensures precise, repeatable motion with long travel.

Based on Tooth Profile

Involute Tooth Gears

- Smooth transmission, constant speed, self-correcting gear meshing.

- Easy alignment, fixed pressure angle, highly interchangeable.

- Ideal for high-speed, low-backlash, parallel shaft use.

Cycloidal Tooth Gears

- Rolling contact reduces friction; great for low-speed torque.

- Minimal wear, low backlash, smooth under load.

- Compact, shock-resistant, suits cycloidal drives, precision gearboxes.

Straight Tooth Bevel Gears

- Straight tapered teeth connect intersecting shafts at angles.

- Simple, low-cost, for moderate torque, low-speed.

- Used in drills, differentials, printing systems.

Spiral (Curved) Tooth Gears

- Curved teeth enable smoother, stronger gear engagement.

- Quiet, durable at high speeds with continuous meshing.

- Used in cars, aerospace, industrial equipment.

Based on Gear Size

Small Precision Gears

Compact, high-accuracy gears used in instruments, robotics, and electronics, ensuring low backlash, tight tolerances, and smooth micro-motion performance.

Medium Gears

Versatile gears for automotive, machinery, wind turbine gearboxes, and industrial tools, balancing torque capacity, dimensional stability, and moderate load-bearing performance.

Heavy-Duty Gears

Large, robust gears engineered for mining, marine, and heavy machinery, built to endure extreme torque, shock loads, and harsh environments.

Applications

Our custom forged gears are vital for automotive, aerospace, heavy machinery, energy, marine, and agriculture industries, ensuring durability and performance in demanding applications.