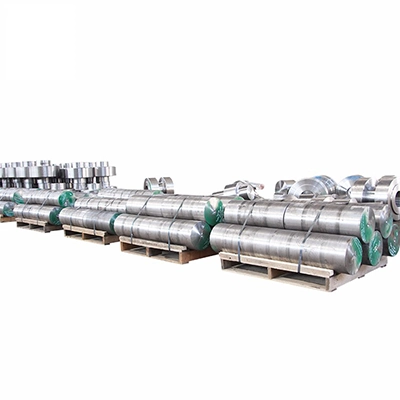

Custom Cylinder Sleeves

- Engineered for extreme durability and precision, our forged cylinder liner sleeves deliver superior wear resistance and thermal performance in demanding environments.

- Customizable in material and structure, they ensure optimal reliability for automotive, marine, and heavy machinery applications.

- Customized to Your Forging Drawing

- Available in Steel and Alloy Materials

- Complies with ASTM, DIN, and ISO Standards

- Certified By ISO9001, PED, and SGS

- Packaged in Fumigated Wood Case, Pallet, or Iron Box

By Structural Design

Our forged cylinder sleeves are precisely designed to meet the needs of modern engines and machines. They are classified into three main types based on structure and function.

Blind Hole Cylinder Sleeves

- Closed at one end; used in directional or sealed systems.

- Ideal for hydraulics, pressure vessels, and special engine designs.

- Reduces leakage, enhances control, and resists high thermal stress.

Through Hole Cylinder Sleeves

- Open at both ends; suits engines and open fluid systems.

- Supports intake, exhaust, or fluid passage in piston assemblies.

- Easy machining, coolant integration, and wide application compatibility.

Flanged Cylinder Sleeves

- Flanged end ensures alignment, sealing, and load-bearing performance.

- Applied in marine engines, compressors, and vibration-sensitive equipment.

- Simplifies installation, prevents shift, and strengthens structural integrity.

By Material

We provide forged cylinder sleeves made from high-performance materials, each offering specific benefits in strength, heat resistance, wear, and corrosion protection.

Carbon Steel Cylinder Sleeves

- Strong and machinable, ideal for general-purpose engine use.

- Cost-effective where corrosion resistance isn’t a priority.

- Common in automotive, agriculture, and small machinery engines.

Stainless Steel Cylinder Sleeves

- Resists corrosion; ideal for marine, food, and chemical environments.

- Handles thermal shock, ideal for long-lasting engine use.

- Used in marine, pharma, and hygienic industrial machines.

Alloy Steel Cylinder Sleeves

- Alloyed for wear resistance, strength, and fatigue durability.

- Performs under load, impact, and temperature changes.

- Used in mining, racing, and industrial applications.

Nickel Alloys Cylinder Sleeves

- Excellent heat and corrosion resistance in extreme environments.

- Maintains strength at high operating temperatures.

- Ideal for aerospace, offshore, and chemical systems.

Titanium Cylinder Sleeves

- Lightweight with excellent corrosion resistance and strength.

- Perfect for motorsports, aerospace, and performance engines.

- Resists fatigue under extreme thermal and mechanical stress.

By Cooling Type

Both dry and wet varieties of our forged cylinder sleeves are offered to accommodate different engine cooling and performance demands.

Dry Cylinder Sleeves

- No direct contact with coolant; use engine block for heat dissipation.

- Easy installation; suitable for engines with consistent thermal conditions.

- Common in motorcycles, gasoline engines, and cost-effective power units.

Wet Cylinder Sleeves

- Contact coolant directly; provide excellent cooling and heat management.

- Require sealing rings; precise installation prevents coolant system leakage.

- Used in diesel, marine, and industrial engines needing strong cooling.

By Installation Method

Press-fit, shrink-fit, and slip-fit techniques are used by our forged cylinder sleeves to guarantee correct alignment, stability, and sealing in a range of applications.

Press-Fit Sleeves

Shrink-Fit Sleeves

Slip-Fit Sleeves

Application

Our forged cylinder sleeves are made for tough conditions, offering strength, accuracy, and heat resistance. They’re used in many industries and machines, including:

Automotive Cylinder Sleeves

Marine Cylinder Sleeves

Hydraulic Cylinder Sleeves

Compressor Sleeves

General Engine Cylinder Sleeves