Surface-treated Carbon Steel Castings

- Net-shape casting: Near-final geometry reduces or eliminates secondary machining, saving time and tooling cost.

- High strength & toughness: Carbon steel grades provide robust mechanical performance for heavily loaded or impact tools.

- Rich surface treatments: Hot-dip galvanizing, zinc and chrome plating, painting, powder coating, polishing, anodizing, black oxide, and more.

- Fine surface finish: Casting roughness as low as Ra1.6–3.2 with tight machining tolerance up to ±0.009 mm.

- Flexible production capacity: 100–150 tons per month with stable 45-day lead time for regular orders.

Technical Specifications

| Item | Details |

| Product Name | Surface-treated Carbon Steel Castings |

| Material | Carbon steel (per GB, ASTM, AISI, DIN, BS, JIS standards) |

| Material Standards | EN, BS, AISI, ASTM, JIS |

| Casting Processes | Precision investment casting, sand casting |

| Weight Range – Carbon Steel | 1 g – 99 kg (investment); sand casting from 0.5 kg |

| Minimum Wall Thickness | Approx. 0.5 mm |

| Casting Surface Roughness | Ra1.6–3.2 (typical investment); general range Ra3.2–6.4 |

| Machined Surface Roughness | Ra 0.8–1.6 |

| Machining Tolerance | Up to ±0.009 mm |

| Surface Treatment Options | Hot-dip galvanising, zinc plating, chrome plating, spray painting, powder painting, polishing, anodising, black oxide |

| Supply Capacity | 100–150 tons per month |

| Delivery Time | About 45 days |

Customization Options

- Choice of carbon steel grade according to strength, hardness, and toughness requirements.

- Tool geometry, wall thickness, and functional features per 2D/3D drawings or samples.

- Selection of casting process (investment or sand) based on size and precision needs.

- Specified tolerances and machining allowances for cutting edges, jaws, or clamping surfaces.

- Surface treatment method, thickness, color, and corrosion-resistance level.

- Optional heat treatment, hardness range, and testing plan (hardness, tensile, impact, etc.).

- Marking, logo engraving, and export packaging to match OEM or brand requirements.

Applications

- Sewing and textile machinery tools and accessories

- Printing and packaging machinery components

- Hand tools and plier bodies for industrial or DIY markets

- Hardware and fastening tools for construction and installation

- Marine and gardening tools requiring durable, corrosion-protected surfaces

- General mechanical, jig, and fixture components in workshops and factories

Production Process

Our precision casting production process integrates wax modeling, automated shell making, controlled pouring, heat treatment, and machining to ensure dimensional accuracy, integrity, and quality.

Wax Injection

Shell Making

Shell Baking

Pouring

Shot Blasting

Heat Treatment

Machining

Inspection

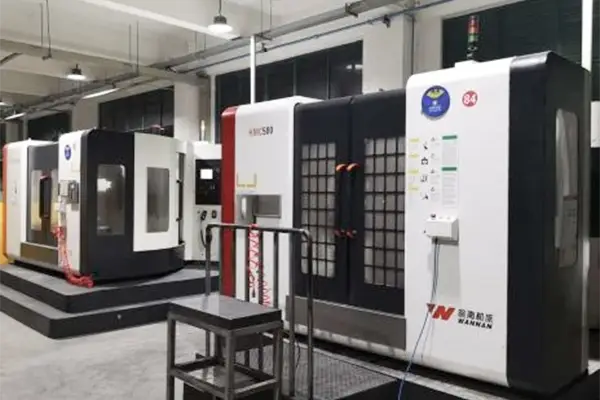

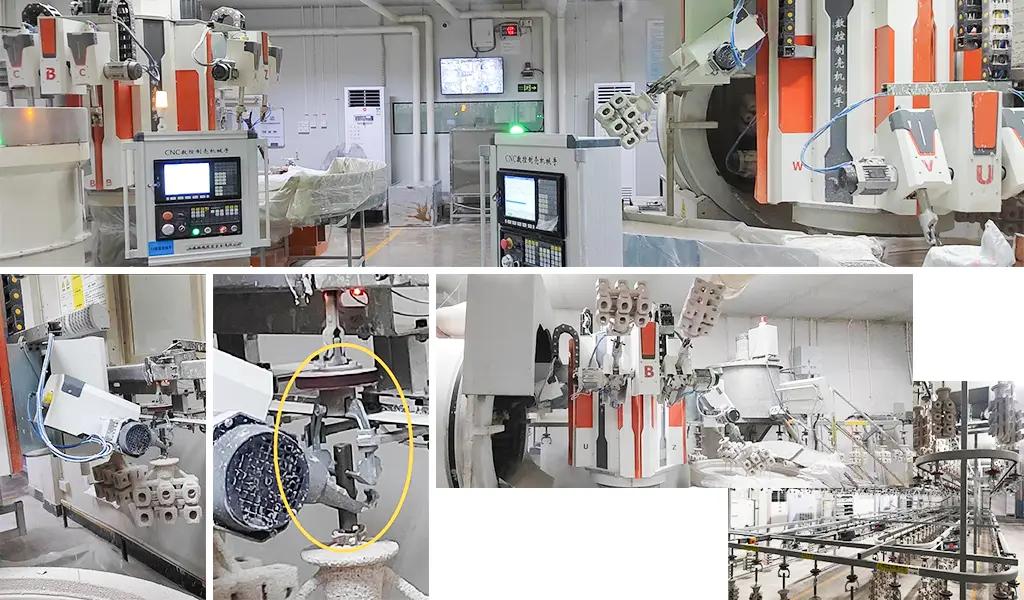

Advanced Workshop

Advanced workshops include wax model production, CNC robotic shell making, semi-automatic pouring, baking furnaces, and machining centers supporting automation, efficiency, flexibility, and operations.

Medium Temperature Wax Workshop

Low Temperature Wax Workshop

9-axles CNC Shell-making Robot Arm Workshop

Semi-auto Pouring Machine

Baking Furnace

Horizontal CNC Machining Center

New Shell Making Automation Line

New shell making automation line optimizes reduction processes, improves production efficiency, ensures reliable equipment operation, extends running time, and significantly reduces labor intensity overall.

Shell Making Automation Line No. 01 – Small & Medium Parts

Automated shell making line for small and medium castings improves shell uniformity, reduces manual intervention, and enhances production stability and efficiency.

Shell Making Automation Line No. 02 – Large Parts

Specialized automation line supports large investment castings, handling complex geometries and higher weights while maintaining shell strength and process reliability.

Shell Making Automation Line No. 03 – Investment Casting

Optimized shell making system streamlines reduction processes, improves efficiency, ensures long-term equipment reliability, and significantly reduces labor intensity.

Quality Inspection

Comprehensive quality inspection system covering materials, processes, dimensions, and final products to ensure traceability, consistency, and full compliance with customer specifications.

Zeiss CMM Machine

X-ray Flaw Detector

100T Horizontal Tensile Testing Machine

Rockwell Hardness Standard Machine

Logistics & Delivery

Monthly Capacity: 500–1000 tons.

Packing: Wooden crates, steel frames, or per client request.

Shipment: By Sea (recommended, saves cost for forging parts) / By Air (fast but expensive).

Payment Terms: 30% deposit with balance via B/L copy; or 100% L/C at sight.

Delivery Terms: FOB, CIF, CNF.