Forging remains one of the oldest yet most forward-looking manufacturing methods in the world. In today’s precision-driven industries—from automotive to aerospace—hot forging services have evolved from brute-force metal shaping to a digitally controlled, quality-engineered process that defines modern component reliability.

The Resurgence of Forging in the Modern Era

At a time when additive manufacturing and CNC machining dominate headlines, hot forging quietly reclaims its place as the backbone of heavy-duty manufacturing. It offers unmatched mechanical integrity, cost efficiency for large production runs, and a proven track record for parts that must endure high stress, fatigue, and temperature extremes.

In the wake of supply-chain disruptions and material shortages during the early 2020s, manufacturers across Europe, Asia, and North America rediscovered the strategic value of local forging houses. Forging companies that invested in induction heating, process simulation, and digital quality tracking found themselves better positioned to serve OEMs seeking resilience and traceability.

What Is Hot Forging?

Hot forging is the process of plastically deforming metal at a temperature above its recrystallization point. Unlike cold forging or machining, which can introduce strain hardening or grain misalignment, hot forging ensures grain refinement, ductility, and anisotropic strength alignment along the shape of the component.

Typical temperature ranges:

| Material Type | Hot Forging Temperature Range (°C) | Common Applications |

| Carbon steel | 950–1250 | Shafts, gears, axles |

| Stainless steel | 1000–1200 | Valves, medical tools |

| Aluminum alloys | 350–520 | Aerospace fittings |

| Titanium alloys | 700–950 | Jet-engine parts |

| Nickel superalloys | 950–1150 | Turbine blades |

At these elevated temperatures, metals exhibit reduced flow stress, enabling the shaping of complex geometries while minimizing internal cracking.

Historical Evolution of Hot Forging

The evolution of forging mirrors the technological history of civilization. The hammer-and-anvil era gave way to water-driven trip hammers, then to hydraulic presses, mechanical hammers, and eventually computer-aided closed-die systems.

Figure 1. Historical milestones in forging technology

| Era | Key Innovation | Industrial Impact |

| Ancient (before 1000 BCE) | Manual hammer forging | Birth of weapon and tool making |

| Industrial Revolution | Steam and drop hammers | Mass production of hardware |

| Mid-20th century | Hydraulic presses, heat control | Rise of aerospace and automotive forging |

| Late 20th century | CAD/CAM & FEA simulation | Design-driven component optimization |

| 21st century | Industry 4.0, IoT integration | Real-time monitoring, predictive maintenance |

Today’s forging plants use thermomechanical simulation to virtually predict metal flow and die wear before any physical run, cutting development time drastically.

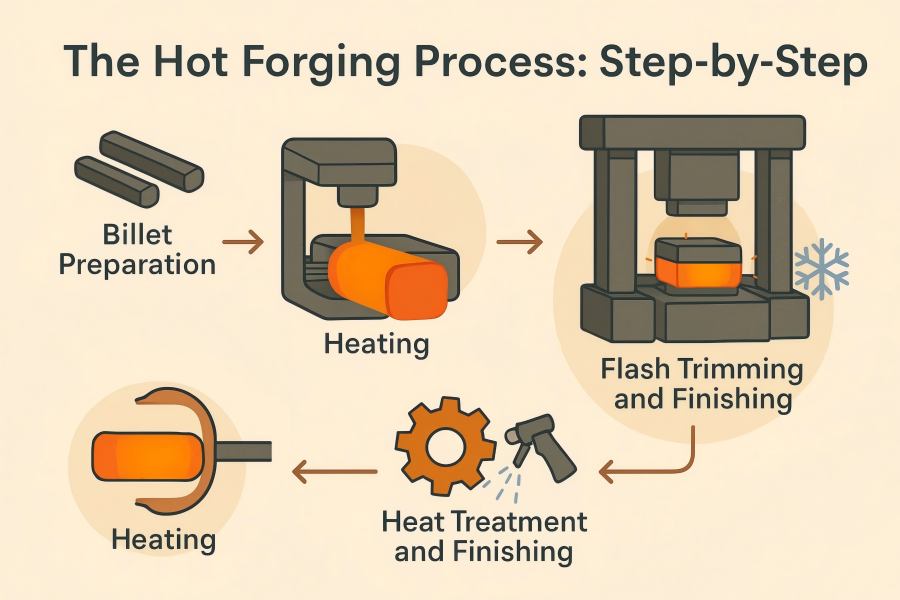

The Hot Forging Process: Step-by-Step

Though the core principle—deforming heated metal under pressure—remains unchanged, the sequence and control systems have become far more sophisticated.

Billet Preparation

Raw bars or rods are first cut into precise billets using automatic shearing or sawing systems. Dimensional accuracy at this stage directly affects material utilization and flash formation.

Heating

Modern hot forging relies on induction heaters or gas furnaces capable of uniform heating to ±10 °C across the billet. Temperature sensors and pyrometers ensure that metal remains above the recrystallization temperature throughout deformation.

Figure 2. Induction heating sequence for steel billets

| Stage | Temperature (°C) | Duration (s) | Objective |

| Pre-heat | 650 | 30 | Homogenize core temperature |

| Soak | 1150 | 60 | Achieve forging ductility |

| Transfer | 1050 | 10 | Maintain temperature before die contact |

Forging (Deformation)

Depending on the die configuration and energy source, forging can occur via several modes:

- Open-die forging: The billet is compressed between flat dies, gradually reducing cross-section and elongating the workpiece.

- Closed-die (impression-die) forging: Dies contain cavities that shape the metal into near-net geometries.

- Press forging: Continuous, controlled deformation by hydraulic or mechanical press; ideal for large parts.

- Hammer forging: High-energy impact shaping; still used for specific tool steels and aerospace forgings.

Each method balances productivity, die life, and dimensional control.

Flash Trimming and Cooling

In closed-die processes, excess material squeezed out between die halves forms a thin “flash.” This flash is trimmed off in dedicated presses. Controlled air or water cooling follows—critical for achieving a consistent microstructure.

Heat Treatment and Finishing

Forged parts undergo post-forging treatments such as annealing, quenching, and tempering to refine grain structure and enhance mechanical properties. Finishing operations may include shot blasting, machining, surface coating, or non-destructive testing (NDT).

Core Advantages of Hot Forging

Hot forging’s resurgence is rooted in a simple yet powerful fact: it produces parts that are stronger and more fatigue-resistant than those made by casting or machining alone.

Mechanical Benefits:

- Directional grain flow: Enhances impact toughness and resistance to fatigue crack propagation.

- Improved metallurgical integrity: Eliminates porosity and segregation common in castings.

- Enhanced machinability: Controlled deformation and recrystallization improve cutting performance.

- High-dimensional accuracy: When paired with precision dies and temperature control, tolerances as tight as ±0.5 mm are achievable.

Economic Benefits:

| Factor | Hot Forging | Casting | CNC Machining |

| Material utilization | 85–95 % | 60–70 % | 40–60 % |

| Production rate | High (seconds/piece) | Moderate | Low |

| Strength-to-weight ratio | Excellent | Fair | Variable |

| Tooling cost | Moderate | High (molds) | Low |

| Ideal for | High-volume durable parts | Complex hollow shapes | Low-volume prototypes |

These advantages make hot forging indispensable in automotive crankshafts, aircraft landing gears, mining tools, and heavy-machinery links.

Forging Equipment and Technologies

Modern hot forging plants integrate automation, sensors, and robotics to deliver consistent quality with minimal operator intervention.

Hammers and Presses

| Type | Working Principle | Typical Capacity | Application |

| Mechanical hammer | Flywheel stores energy, releases impact | Up to 50 kJ | Small to medium parts |

| Hydraulic press | Fluid pressure applies steady force | 500–10 000 tons | Large die forgings |

| Screw press | Rotational inertia drives ram | 100–5000 tons | Precision components |

| Isothermal press | Maintains uniform die temperature | 200–2000 tons | Titanium & superalloys |

The selection depends on energy requirements, deformation speed, and part geometry.

Induction Heating Systems

Energy-efficient, programmable induction furnaces allow rapid heating and selective temperature profiling, minimizing oxidation and decarburization.

Robotics and Automation

Forging robots handle billet transfer, die lubrication, and trimming in high-temperature environments, improving operator safety and reducing cycle time by 15–30 %.

Simulation and Digital Twins

Finite element modeling (FEM) now predicts metal flow, strain, die stress, and thermal gradients, while digital twins link simulation data with real-time shop-floor sensors for adaptive control.

Common Materials Used in Hot Forging

Hot forging accommodates nearly every industrial alloy family, though material behavior varies widely under thermal deformation.

Steels

Carbon and alloy steels remain dominant due to their versatility, cost efficiency, and post-heat-treatment strength.

Typical forged steel grades:

| Grade | Composition Highlights | Use Case |

| 1045 | Medium carbon | Shafts, gears |

| 4140 | Cr-Mo alloy | Axles, crankshafts |

| 4340 | Ni-Cr-Mo alloy | Landing gear, heavy shafts |

| 8620 | Ni-Cr-Mo case-hardening steel | Gears, transmission parts |

Aluminum Alloys

Lightweight and corrosion-resistant, aluminum forgings are prevalent in automotive and aerospace structural components. Grades like 6061, 7075, and 2024 are common for their high strength-to-weight ratios.

Titanium and Superalloys

For high-temperature, high-performance environments, titanium and nickel-based superalloys dominate. Their hot forging requires isothermal or near-isothermal control to prevent surface cracking and maintain microstructural homogeneity.

Figure 3. Hot-forged material categories by service environment

| Environment | Typical Material | Service Example |

| High stress, room temperature | Carbon steels | Automotive axles |

| High temperature (>700 °C) | Nickel superalloys | Turbine blades |

| Corrosive/weight-critical | Titanium alloys | Aerospace frames |

| Conductive/lightweight | Aluminum alloys | EV battery enclosures |

Forging Defects and Quality Control

Even with automation, hot forging requires vigilant quality control. Common defects include laps, underfills, die mismatches, and scale inclusions.

Table: Major forging defects and preventive actions

| Defect | Root Cause | Prevention |

| Laps | Excessive flash or improper die design | Optimize die parting line; control material flow |

| Underfill | Inadequate material volume or low temperature | Correct billet size; ensure full die filling |

| Cracks | Overheating, improper cooling, or impurities | Maintain proper forging temperature; clean billets |

| Die wear | Excessive cycles, poor lubrication | Use die coatings (e.g., graphite, molybdenum); schedule maintenance |

Non-Destructive Testing (NDT) Techniques

- Ultrasonic testing (UT): Detects internal voids and inclusions.

- Magnetic particle inspection (MPI): Reveals surface and subsurface cracks in ferromagnetic metals.

- Dye penetrant inspection (DPI): Highlights open surface cracks in non-ferrous materials.

- Radiographic testing (RT): Used for critical aerospace components.

Modern forging facilities integrate these inspections into automated cells for faster turnaround.

Hot Forging vs. Cold Forging

While both belong to the metal-forming family, their process characteristics and outputs differ dramatically.

| Criteria | Hot Forging | Cold Forging |

| Temperature | Above recrystallization | Room temperature |

| Ductility | High | Low to moderate |

| Dimensional accuracy | Moderate | Excellent |

| Surface finish | Oxidized | Smooth |

| Die life | Shorter | Longer |

| Typical volume | Large and heavy parts | Small precision parts |

| Residual stress | Low | High |

| Material waste | Low (due to flash control) | Very low |

Cold forging excels in producing small, high-volume precision parts like bolts and screws. Hot forging, conversely, is ideal for large structural parts requiring superior mechanical integrity.

Applications Across Industries

Automotive

The automotive sector is the largest consumer of forged components. Crankshafts, connecting rods, steering arms, gears, and wheel hubs are almost exclusively forged due to their fatigue strength.

Key trend: Lightweight forged aluminum suspension components in electric vehicles (EVs) to offset battery weight.

Aerospace

Aircraft engine and landing-gear systems rely on titanium and nickel superalloy forgings. Forging ensures directional grain flow and eliminates casting porosity—a crucial factor in flight-critical components.

Energy and Oil & Gas

Hot forging is vital for producing turbine shafts, drill collars, flanges, and high-pressure valves. Components must withstand corrosion, cyclic loading, and high temperatures.

Construction and Mining

Excavator links, hammer tools, and rock-drill bits require immense toughness, achieved only through forged steel microstructures.

Medical and Defense

Surgical instruments and defense hardware (gun barrels, armor components) use forged stainless steels and titanium for precision and reliability.

Figure 4. Industrial distribution of hot forging applications

| Sector | Estimated Global Share (%) |

| Automotive | 45 |

| Aerospace | 15 |

| Energy / Oil & Gas | 20 |

| Construction & Mining | 10 |

| Defense & Medical | 10 |

Environmental and Sustainability Considerations

Forging’s image as an energy-intensive, high-emission process is changing rapidly. Modern plants are embracing electrification and closed-loop systems.

Energy Efficiency

Induction heating consumes up to 30 % less energy than traditional gas furnaces. Regenerative burners and waste-heat recovery systems further reduce fuel consumption.

Material Utilization

Advanced die design and flashless forging improve material yield by 5–10 %. In high-volume automotive applications, this translates into thousands of tons of steel saved annually.

Lubrication and Waste Reduction

Eco-friendly lubricants replace graphite-oil mixes, lowering CO₂ emissions and worker exposure to particulates. Recyclable die-coating systems reduce hazardous waste.

Circular Manufacturing

Forging scrap—trimmed flash, defective billets, and machining chips—is 100 % recyclable, feeding directly back into steel and aluminum melting furnaces.

Service Models in the Forging Industry

Hot forging services operate under several business and supply models.

| Service Model | Description | Typical Client |

| Job-shop forging | Custom parts produced per drawing/spec | Small OEMs, R&D labs |

| Contract forging | Long-term supply agreements for serialized parts | Automotive Tier 1 suppliers |

| Integrated forging & machining | Forging plus finish machining and assembly | Aerospace & defense |

| Build-to-print (BTP) | Client provides full design; forgers ensure process compliance | Energy, oil & gas |

| Design-assist forging | Joint development; forger contributes manufacturability expertise | Start-ups, prototyping |

Increasingly, service providers differentiate themselves by offering design simulation, die-life management, and post-processing traceability through digital platforms.

The Role of Simulation and AI in Forging

Artificial intelligence now complements traditional metallurgical expertise. Machine-learning models predict forging load, die wear, and defect likelihood from historical production data.

Case Example: AI-Based Die Life Prediction

A European forging firm used neural networks to analyze 200 000 forging cycles. By correlating die temperature and lubricant intervals with wear depth, AI models extended die life by 22 % and saved approximately €300 000 annually.

Process Optimization via Digital Twin

A digital twin integrates sensor data (temperature, pressure, stroke) with FEA simulation, allowing operators to adjust press parameters in real time to prevent defects or improve energy usage.

Post-Forging Operations and Value-Added Services

Forging is often just the first step in a chain of precision finishing processes that transform a rough shape into a ready-to-install component.

Machining and Grinding

CNC machining removes minimal material since forged shapes are near-net. Precision grinding and honing achieve tolerances down to ±0.02 mm for aerospace applications.

Heat Treatment

Customized cycles achieve required mechanical properties:

- Normalization: refine grain and relieve stress.

- Quenching & Tempering: raise tensile strength.

- Solution Treatment (for aluminum/titanium): homogenize alloying elements.

Surface Treatments

- Shot peening: introduces compressive surface stress, improving fatigue life.

- Nitriding / Carburizing: surface hardening for wear resistance.

- Anodizing (aluminum): corrosion and aesthetic enhancement.

Inspection and Certification

Hot-forged components, especially in aerospace and defense, must conform to standards such as AMS 4928, ASTM A29, or ISO 10243. Certification covers chemical composition, mechanical properties, microstructure, and dimensional compliance.

Economic Landscape of the Forging Industry

As of the mid-2020s, the global forging market exceeds USD 85 billion, projected to reach nearly USD 120 billion by 2030, driven by renewable-energy infrastructure and electrified transportation.

Regional Highlights

| Region | Market Share (%) | Key Growth Drivers |

| Asia-Pacific | 55 | Automotive hubs in China, India, Japan |

| Europe | 20 | Aerospace & green-steel initiatives |

| North America | 18 | Defense and EV supply chains |

| Others (MEA, LatAm) | 7 | Oil & Gas infrastructure |

Reshoring and regional diversification post-pandemic are prompting new investments in medium-capacity forging presses across the United States and Southeast Asia.

Emerging Trends and Innovations

Near-Net-Shape and Precision Forging

Advances in die design enable parts to emerge from the press almost to final geometry, slashing machining time by 50 %.

Hybrid Manufacturing

Forging combined with additive manufacturing (AM) fuses the best of both worlds: forged mechanical properties with printed complexity. Preforms can be forged and finished by AM deposition for intricate channels or cooling paths.

Smart Forging Plants

IoT-connected presses monitor ram speed, die temperature, and load in real time. Predictive maintenance algorithms alert technicians before failure, ensuring near-zero downtime.

Green Forging

Transition to hydrogen-based heating and electric presses is underway. Scandinavian and Japanese forges have piloted net-zero plants using renewable electricity and recycled feedstock.

Challenges Facing Hot Forging Services

Despite innovation, the industry faces persistent challenges:

- Die cost and lead time: Precision dies can consume 15–25 % of project budgets.

- Skilled labor shortages: Forging engineers and metallurgists are aging; new talent is scarce.

- Energy volatility: Electricity and gas price fluctuations heavily influence profitability.

- Supply-chain resilience: Alloy scarcity or geopolitical disruptions can stall production.

- Quality certification bottlenecks: Meeting AS9100 or ISO/TS standards remains resource-intensive for small forges.