In modern engine design, choosing the right cylinder sleeve material is crucial for efficiency, durability, and heat management. As engines advance and propulsion technologies diversify, materials science continues to meet growing demands.

From the robust cast iron sleeves of early engines to the lightweight aluminum and high-performance nickel-based alloys in today’s systems, innovation has redefined the balance between strength, weight, and heat transfer. Each material suits different needs—motorsports, marine, heavy-duty, or hybrid applications.

The Functional Role of Cylinder Sleeves

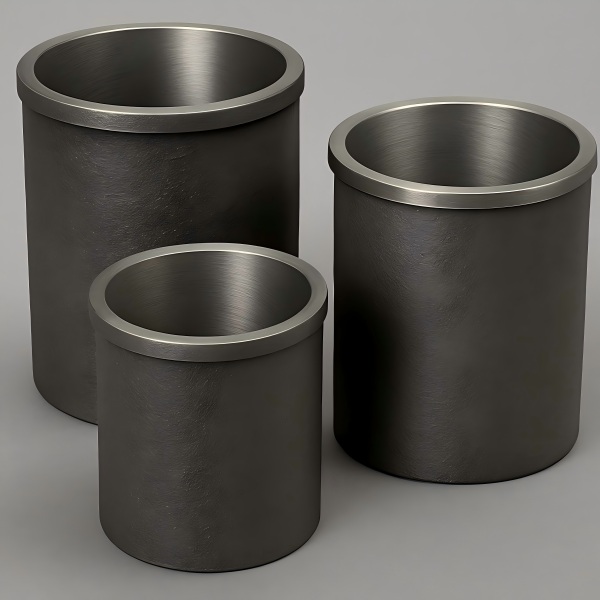

Cylinder sleeves, also known as cylinder liners, form the wear-resistant inner surface of an engine’s combustion chamber. They provide a durable interface between the piston rings and the cylinder wall, confining combustion pressure while facilitating efficient heat transfer to the cooling system.

In modern applications, sleeves must fulfill multiple functions simultaneously:

- Maintain dimensional stability under extreme heat and pressure.

- Resist wear and corrosion from lubricants and combustion byproducts.

- Promote thermal efficiency by conducting heat away from the piston crown.

- Enable easy replacement or customization, reducing total engine rebuild costs.

These requirements increase in complexity as engines get lighter, smaller, and more potent. The challenge lies not only in the base strength of the material but also in its microstructural behavior, thermal expansion compatibility, and machinability during custom manufacturing.

Cast Iron Cylinder Sleeves

Cast iron has long been the standard for cylinder sleeves due to its excellent wear resistance, dimensional stability, and self-lubricating properties. Gray cast iron, which contains graphite flakes, is particularly favored for its ability to retain oil and reduce friction. High-chromium or molybdenum-alloyed cast irons further improve hardness and temperature endurance.

Typical compositions include:

- Carbon (2–3.5%): provides hardness and wear resistance.

- Silicon (1–3%): stabilizes the graphite structure.

- Manganese, Chromium, Molybdenum: enhance strength and fatigue resistance.

Manufacturing Process and Machinability

Cast iron sleeves are often produced through centrifugal casting or sand casting, followed by precision honing and grinding. The casting process allows for tight grain control and uniform wall thickness. Moreover, the material’s machinability is favorable, making it cost-effective for large-scale production.

Thermal and Mechanical Performance

The main advantage of cast iron lies in its ability to resist wear under poor lubrication conditions. Its relatively low thermal expansion coefficient minimizes deformation, ensuring consistent piston-ring sealing. However, its thermal conductivity is significantly lower than aluminum’s, leading to slower heat dissipation and heavier overall weight.

| Pros | Cons |

| Excellent wear and fatigue resistance | High density (~7.2 g/cm³) adds significant engine weight |

| Stable under high combustion pressures | Poor thermal conductivity compared to lighter metals |

| Cost-effective and easy to produce | Limited corrosion resistance in high-moisture environments |

For commercial vehicles, diesel engines, and agricultural machinery, where reliability and cost outweigh the need for weight reduction, cast iron remains the dominant material choice.

Aluminum Cylinder Sleeves

As automotive and aerospace industries push for lightweight solutions, aluminum alloys have emerged as a leading contender for cylinder sleeve construction. Aluminum sleeves, often integrated into aluminum blocks through press-fit, shrink-fit, or plasma-sprayed linerless coatings, offer remarkable weight reduction and superior heat dissipation.

Common aluminum alloys for sleeves include Al-Si (silicon) blends such as A390, which offer high hardness, wear resistance, and excellent castability.

Manufacturing and Customization

Aluminum sleeves are typically produced using gravity casting, die casting, or machining from solid billet stock, depending on performance requirements. Custom aluminum sleeves may include hard anodizing or Nikasil (nickel-silicon-carbide) coatings to improve wear resistance and surface hardness, achieving values up to 600–700 HV.

Their thermal expansion rate is higher than that of cast iron, which requires careful engineering to maintain proper clearances during operation. Modern engines address this through controlled interference fits and thermal barrier coatings that maintain geometric stability.

Thermal and Structural Behavior

Aluminum’s greatest advantage lies in its superior thermal conductivity (~170–210 W/m·K)—more than four times that of cast iron. This enhances overall combustion efficiency by facilitating quick heat movement and avoiding localized hot spots. Additionally, the weight reduction enhances vehicle dynamics and fuel economy.

| Pros | Cons |

| Lightweight (~2.7 g/cm³) and thermally efficient | Requires surface treatment to prevent galling and wear |

| Enables faster warm-up and improved fuel efficiency | High thermal expansion may lead to clearance challenges |

| Can be integrated into monoblock designs for weight savings | Lower fatigue strength compared to nickel alloys or iron |

For high-performance motorcycles, electric-hybrid engines, and lightweight racing applications, aluminum sleeves are the optimal balance of weight, cooling efficiency, and performance tunability.

Nickel-Based Cylinder Sleeves

Nickel-based alloys, such as Inconel 718, Monel 400, or Ni-Cr-Mo systems, represent the pinnacle of metallurgical innovation in custom cylinder sleeves. These materials were initially developed for aerospace and turbine applications where extreme heat and corrosion resistance were critical.

Nickel alloys are distinguished by:

- High-temperature strength retention (up to 800°C)

- Excellent corrosion and oxidation resistance

- Superior fatigue and creep resistance under cyclic loading

The presence of elements like chromium, molybdenum, niobium, and titanium forms complex intermetallic phases (e.g., γ′ and γ″) that reinforce the microstructure and maintain mechanical integrity at elevated temperatures.

Manufacturing Challenges and Customization

Producing nickel-based sleeves is a technically demanding process. Vacuum induction melting (VIM) and powder metallurgy (PM) are often employed to achieve homogeneous microstructures. Custom sleeves are typically CNC-machined from forged billets or precision-cast blanks, with additional HIP (Hot Isostatic Pressing) to eliminate porosity.

Due to their hardness (up to 350–450 HB) and toughness, machining nickel alloys requires advanced tooling and cooling strategies. Consequently, the cost of production is significantly higher than for cast iron or aluminum.

Performance Characteristics

Nickel-based sleeves excel in extreme-duty engines, such as those used in aerospace auxiliary units, marine propulsion, and high-performance motorsports. Their thermal conductivity (~20–30 W/m·K) is lower than aluminum’s, but their ability to maintain strength and shape under high temperature and pressure conditions makes them indispensable in applications with sustained high thermal loads.

| Pros | Cons |

| Exceptional high-temperature stability and fatigue resistance | High cost and machining difficulty |

| Outstanding corrosion and oxidation resistance | Moderate thermal conductivity |

| Excellent structural integrity for turbocharged or boosted systems |

In practice, nickel-based sleeves are chosen for extreme durability rather than cost efficiency, offering unmatched reliability in environments where component failure is not an option.

Comparative Analysis

| Property | Cast Iron | Aluminum | Nickel-Based Alloy |

| Density (g/cm³) | 7.0–7.3 | 2.6–2.8 | 8.1–8.5 |

| Thermal Conductivity (W/m·K) | 45–60 | 170–210 | 20–30 |

| Tensile Strength (MPa) | 250–400 | 200–450 | 900–1200 |

| Wear Resistance | Excellent | Moderate (requires coating) | Excellent |

| Corrosion Resistance | Moderate | Moderate–Good | Excellent |

| Machinability | Good | Excellent | Poor–Moderate |

| Cost Level | Low | Moderate | Very High |

This comparison highlights that each material occupies a specific niche:

- Cast iron remains the cost-effective choice for conventional engines.

- Aluminum dominates applications emphasizing weight and heat transfer.

- Nickel-based alloys serve as the premium solution for extreme reliability and thermal endurance.

Emerging Technologies and Hybrid Material Systems

The future of cylinder sleeve technology lies not in one material but in hybrid composites and surface engineering. Advanced processes such as laser cladding, thermal spraying, and additive manufacturing allow manufacturers to combine the best attributes of multiple materials.

Composite Sleeve Designs

Hybrid sleeves can integrate a lightweight aluminum body with a nickel-based wear layer or ceramic coating, achieving both thermal conductivity and surface hardness. These multi-material systems reduce total mass while maintaining protection against scuffing and distortion.

Additive Manufacturing and Tailored Microstructures

Metal additive manufacturing (3D printing) enables gradient materials, where composition changes gradually from the inner surface to the outer layer. For example, a nickel-rich inner surface can resist combustion erosion, while the aluminum outer structure optimizes heat dissipation. This concept of functionally graded materials (FGMs) could redefine sleeve customization for specific engine types.

Coatings and Surface Treatments

The use of diamond-like carbon (DLC), ceramic oxide, and Nikasil coatings enhances surface hardness without adding significant weight. These coatings also minimize friction, improving efficiency and extending service intervals.

Design Considerations for Custom Cylinder Sleeves

When designing a custom sleeve, engineers must balance mechanical performance, thermal compatibility, and manufacturing feasibility. Key parameters include:

- Operating Environment: Temperature, pressure, and load cycles determine material selection.

- Engine Block Material: The coefficient of thermal expansion must be compatible to prevent distortion.

- Lubrication and Cooling Systems: Materials with higher conductivity can better dissipate heat in compact engine architectures.

- Production Volume and Cost Constraints: Cast iron suits high-volume manufacturing; nickel alloys fit low-volume, high-value builds.

- Repair and Maintenance Cycles: Sleeve replaceability and re-machinability can influence total life-cycle costs.

Manufacturers specializing in custom metal forging services and precision casting continue to innovate by optimizing material chemistry and heat treatment to extend performance life while meeting sustainability and cost targets.

Environmental and Economic Implications

Material innovation in cylinder sleeves also reflects the broader industrial push toward energy efficiency and carbon reduction. Lightweight aluminum sleeves contribute directly to lower fuel consumption, while durable nickel alloys minimize replacement frequency, reducing material waste.

Moreover, emerging recycling technologies now allow closed-loop recovery of both aluminum and nickel alloy components. Foundries adopting low-carbon smelting and green forging processes further reduce the environmental footprint of cylinder sleeve manufacturing.

Economic factors remain critical: cast iron maintains an advantage in affordability, but as electrification and high-efficiency hybrid engines demand greater thermal management, the cost-performance ratio of aluminum and nickel alloys becomes increasingly attractive.

Application Case Studies

Automotive Sector

Performance automotive engines, such as those in Formula racing or endurance vehicles, increasingly favor aluminum or nickel-coated aluminum sleeves to achieve high RPM operation with minimal friction loss.

Marine and Heavy-Duty Engines

Marine diesel engines still rely on thick-wall cast iron sleeves for their exceptional wear resistance and ease of field replacement, especially in long-haul cargo applications.

Aerospace and Turbomachinery

Nickel-based alloys dominate where heat resistance outweighs weight concerns, such as in auxiliary power units (APUs) or high-compression aircraft engines. Their performance under oxidative and cyclic stress remains unmatched.