Die casting produces precise metal pieces with fine features and smooth surfaces. There are two main methods: die casting in cold chambers and hot chambers. Despite shaping metal, their materials, cycle durations, pricing, and applications are different. Comprehending these distinctions aids manufacturers in selecting the appropriate approach.

What is Die Casting?

High-pressure injections of molten metal are made into the mold. Usually, the metal is injected into a steel or other sturdy mold to produce pieces with superb detail, smooth surfaces, and high dimensional accuracy. Complex metal parts may be produced in large quantities thanks to this manufacturing process’s exceptional efficiency.

Die casting‘s main advantage is its capacity to create parts with reliable quality and shape, which makes it a popular technique in sectors including consumer goods, electronics, automotive, and aerospace.

What Is Hot Chamber Die Casting?

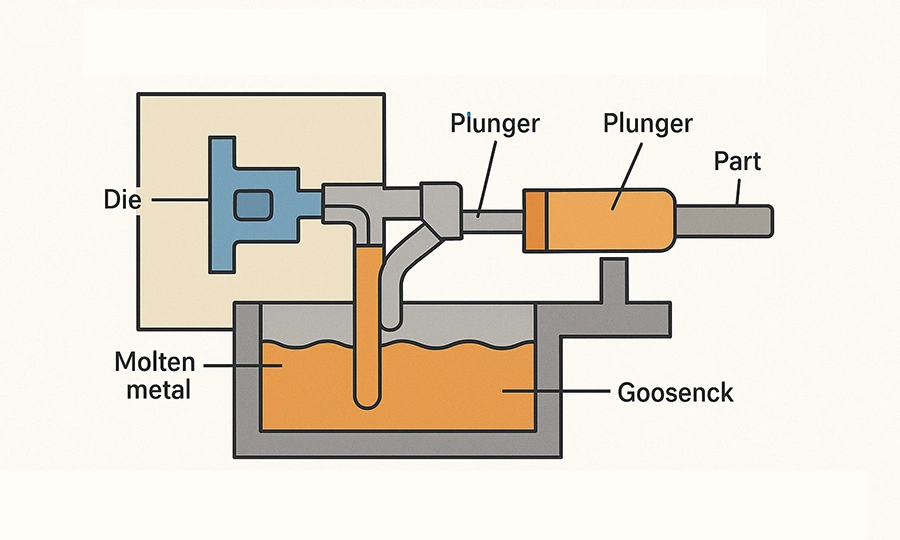

In the process of hot chamber die casting, the metal injection system is submerged directly in the molten metal. Usually, a furnace attached to the injection system receives the molten metal.

Lead alloys, magnesium, zinc, and other metals with low melting points are the ideal candidates for this process. Molten metal is forced into the die at high pressure via a submerged piston in the injection mechanism used in hot chamber die casting.

How Hot Chamber Die Casting Works

In hot chamber die casting, the chamber, nozzle, and other components are exposed to the molten metal throughout the entire process. The molten metal is injected into the die by a plunger or piston once the injection system has been immersed in it.

The molten metal forms the desired portion as it fills the mold and takes on the shape of the cavity. When the metal cools and sets, the mold is opened and the finished object is ejected.

Key Advantages of Hot Chamber Die Casting

| Advantages | Description |

| Faster Cycle Time | The molten metal is directly injected from the furnace, leading to quicker cycles and high productivity. |

| Lower Equipment Costs | Hot chamber die casting requires fewer mechanical components compared to cold chamber casting, reducing the cost of equipment. |

| High Production Efficiency | Suitable for high-volume production of smaller, intricate parts. |

| Smooth Surface Finish | This method offers excellent surface finish quality, making it ideal for parts requiring smooth surfaces without additional finishing. |

| Suitable for Low-Melting Metals | Works best with low-melting metals like zinc and magnesium alloys, which are ideal for high-precision components. |

Key Disadvantages of Hot Chamber Die Casting

| Disadvantages | Description |

| Limited to Low-Melting Metals | Metals having high melting points, such as aluminum, cannot be used in hot chamber die casting since doing so would harm the chamber’s components. |

| Lower Strength Parts | Parts made from metals such as zinc are generally less durable and strong compared to parts made from high-melting metals. |

| Risk of Contamination | Prolonged exposure to high temperatures can cause the alloy in the chamber to degrade, leading to contamination of the parts. |

What Is Cold Chamber Die Casting?

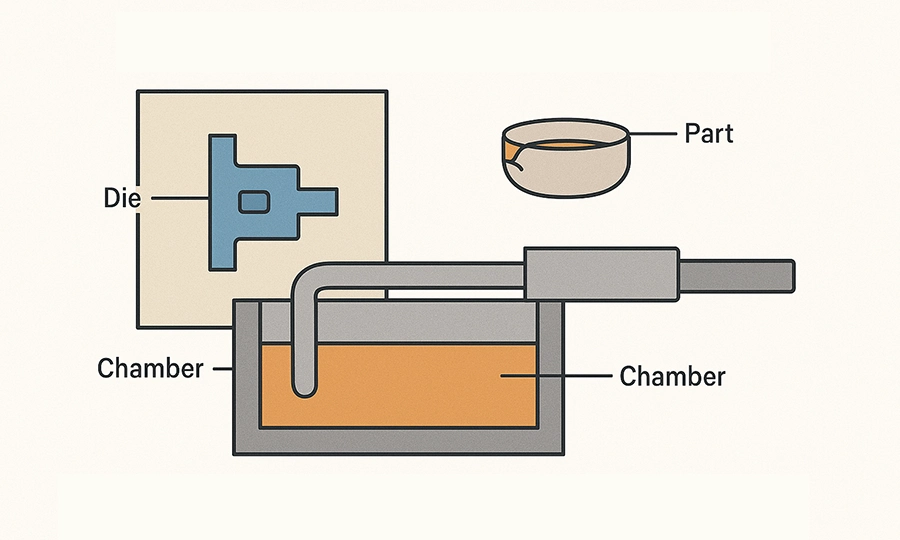

Melted metal does not come into direct contact with the injection system during the cold chamber die casting process. Rather, the molten metal is injected into the mold after being ladled into a separate chamber.

Because it permits the use of metals with higher melting points, like copper alloys, brass, and aluminum, this process is more adaptable. Larger, stronger pieces that need materials that can sustain higher stresses are frequently produced via cold chamber die casting.

How Cold Chamber Die Casting Works

In cold chamber die casting, a ladle is used to physically move the molten metal into the injection chamber, where a piston or plunger injects it into the mold at high pressure.

The main distinction between the injection mechanism and the molten metal is the process’s resemblance to hot chamber die casting. The completed object is expelled from the mold once the molten metal has solidified and filled it.

Key Advantages of Cold Chamber Die Casting

| Advantages | Description |

| Suitable for High-Melting Metals | For metals with high melting points, such as copper alloys and aluminum, cold chamber die casting is perfect. |

| Higher Strength Parts | Cold chamber die cast parts are often stronger and more durable, which makes them perfect for demanding applications. |

| Greater Material Flexibility | Cold chamber die casting is versatile and can handle a wide range of metal alloys, including those used in demanding industries. |

| Better for Larger Parts | This method is more effective for producing larger parts that require higher durability and strength. |

| Lower Risk of Metal Contamination | The separation of molten metal from the injection system reduces the risk of metal degradation and contamination. |

Key Disadvantages of Cold Chamber Die Casting

| Disadvantages | Description |

| Slower Cycle Time | Cold chamber die casting involves more steps, such as ladling molten metal into the chamber, which results in slower cycle times. |

| Higher Equipment Costs | The additional components required, such as ladles and separate chambers, increase the overall equipment costs. |

| More Complex Setup | Cold chamber die casting involves a more intricate setup and maintenance due to the need for additional components to handle molten metal. |

Important Distinctions Between Cold and Hot Chambers Die Casting

The key distinctions between die casting in a hot chamber and a cold chamber are shown in the following table:

| Feature | Hot Chamber Die Casting | Cold Chamber Die Casting |

| Melting Point of Materials | Suitable for low-melting metals like zinc, magnesium, and lead | Suitable for high-melting metals like aluminum, brass, and copper alloys |

| Cycle Time | Faster due to the direct connection to the molten metal | Slower due to the need for ladling molten metal into the chamber |

| Cost of Equipment | Lower cost because of fewer mechanical components | Higher cost due to the need for additional components and equipment |

| Application | Small parts, high-volume production, low-melting alloys | Larger, stronger parts made from high-melting-point metals |

| Strength of Parts | Lower strength, ideal for decorative or lightweight components | Higher strength, suitable for automotive, aerospace, and industrial components |

| Risk of Contamination | Higher risk of contamination due to direct exposure to molten metal | Lower risk of contamination due to the separation of molten metal from the injection system |

| Material Handling | Chamber is immersed in molten metal, making it ideal for low-melting alloys | Molten metal is ladled into the chamber, making it versatile for various metals |

Applications of Hot Chamber and Cold Chamber Die Casting

Both hot chamber and cold chamber die casting are employed across various industries, but they have different ideal applications based on the type of material, part size, and strength requirements.

Applications of Hot Chamber Die Casting

- Automotive Parts: Small components like carburetors, engine parts, and electrical housings that require high precision.

- Consumer Electronics: Small intricate parts such as connectors, housings, and enclosures made from zinc and magnesium alloys.

- Medical Devices: Parts requiring fine details and smooth surfaces, such as enclosures for medical equipment and tools.

- Hardware: Decorative items and other lightweight parts used in furniture, plumbing, and electrical systems.

Applications of Cold Chamber Die Casting

- Automotive Industry: Larger, high-strength parts like engine blocks, transmission cases, and wheels are made from aluminum and copper alloys.

- Aerospace: Strong and durable components like turbine blades, brackets, and housings made from high-melting metals such as aluminum alloys.

- Heavy Machinery: Components that require high durability, such as hydraulic parts and industrial machinery.

- Electronics and Electrical Equipment: Parts that require excellent thermal and mechanical properties, including connectors, casings, and heat sinks made from aluminum alloys.

Material Considerations for Both Die Casting Methods

Choosing the die casting technique to employ depends in large part on the choice of materials. Hot chamber die casting is ideal for zinc, magnesium, and lead alloys, which have lower melting points and flow easily into molds. These materials are ideal for small, intricate parts but offer lower strength compared to metals processed using cold chamber die casting.

In contrast, cold chamber die casting is well-suited for aluminum, copper, and brass, which have higher melting points and require more robust injection systems. These metals provide better strength, thermal resistance, and durability, making them suitable for larger and more complex parts used in industries such as automotive and aerospace.