Heat treatment is essential in forging and casting, improving metals’ strength, hardness, toughness, and ductility through controlled heating and cooling that alters their microstructure.

However, challenges such as warping and oxidation can affect the quality of heat-treated parts. Optimizing production efficiency and attaining the best possible results require an understanding of and attention to these concerns.

1. Warping or Distortion

Warping or distortion refers to the unintended deformation of a material’s shape during heat treatment. This issue is particularly common in larger or more complex components where uneven cooling or heating can cause internal stresses to become unbalanced. Various sections of the material expand or contract at various rates when the metal cools unevenly, which causes deformation.

Causes

- Uneven heating or cooling rates: Materials with varying thicknesses or compositions can absorb heat at different rates, leading to non-uniform expansion or contraction.

- Improper support or fixture during heating: When metal parts are not properly supported, they may warp under their own weight or due to unequal thermal stresses.

- Stress from quenching: The rapid cooling of the material during quenching can result in internal stresses that cause deformation.

Solutions

- Use of proper fixturing and supports: By ensuring that parts are adequately supported during heat treatment, thermal stresses can be better distributed, minimizing the risk of distortion.

- Controlled heating and cooling rates: Gradual, uniform heating and cooling prevent uneven thermal expansion and contraction. This can be achieved through better furnace controls and temperature ramping strategies.

- Post-treatment stress relief: After heat treatment, applying stress-relieving processes, such as tempering or annealing, can help reduce residual stresses and minimize distortion.

2. Oxidation and Scaling on Metal Surfaces

Oxidation occurs when a metal reacts with oxygen at high temperatures, leading to the formation of oxide layers. This is especially problematic for steel and iron-based alloys, as oxidation can form a scale that detracts from the metal’s aesthetic quality and reduces its performance by causing surface defects. Scaling occurs when these oxide layers form and flake off, creating rough, uneven surfaces that need further processing to correct.

Causes

- High temperatures: Prolonged exposure to heat accelerates oxidation, especially for metals such as steel, which react readily with oxygen at elevated temperatures.

- Exposure to oxygen-rich environments: Heat treatment in open air or improperly controlled furnace atmospheres increases the likelihood of oxidation and scaling.

- Lack of protective atmospheres: Inadequate protection during heat treatment allows oxygen to react with the material’s surface, leading to oxidation and scaling.

Solutions

- Use of vacuum or inert atmospheres: Conducting heat treatment in a vacuum or an inert gas environment (such as nitrogen or argon) reduces the contact between the material and oxygen, thus preventing oxidation.

- Proper control of furnace atmosphere: Furnaces should be regularly monitored and adjusted to ensure a neutral or reducing atmosphere. This can be achieved by controlling the oxygen levels inside the furnace.

- Application of protective coatings: Coating metals with protective films before heat treatment prevents direct exposure to oxygen and shields the material from oxidation.

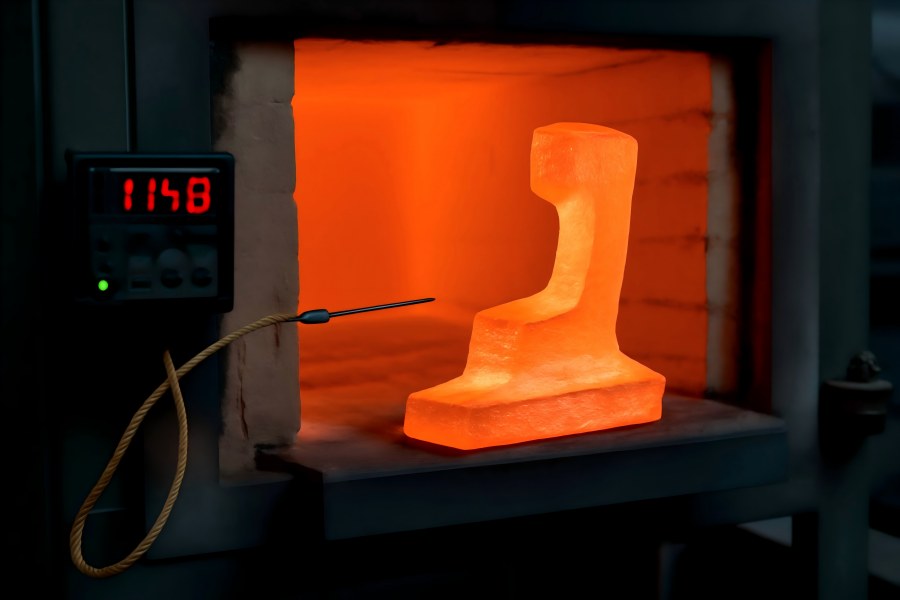

3. Overheating and Overexposure to Heat

Overheating occurs when the metal is exposed to temperatures higher than those recommended for a particular heat treatment process. Overheating can lead to changes in the material’s properties that are undesirable, such as loss of hardness, brittleness, or loss of tensile strength.

Causes

- Incorrect temperature settings: If the furnace is set to too high a temperature, the metal can become overheated, altering its microstructure and degrading its mechanical properties.

- Ineffective monitoring and control: Without accurate monitoring systems, temperatures can exceed recommended ranges, leading to overheating.

Solutions

- Implementation of temperature control systems: Using precise temperature control systems with thermocouples and automated feedback mechanisms can prevent overheating. These systems will ensure the temperature stays within the desired range.

- Regular calibration of equipment: Heat treatment equipment should be regularly calibrated to maintain accurate temperature readings. This includes ensuring that temperature sensors are functioning correctly.

- Temperature sensor monitoring: Place temperature sensors at strategic locations to keep an eye on the heat treatment process and make modifications in real time as needed.

4. Incomplete Hardening

Incomplete hardening occurs when parts of the material do not reach the desired hardness after heat treatment. This can happen when certain areas of the material do not heat to the necessary temperature or when the quenching process is insufficient, resulting in uneven hardness distribution.

Causes

- Insufficient heating: If the material is not heated to the correct temperature, it may not undergo the required phase transformation, leading to areas that are not fully hardened.

- Incorrect or uneven quenching: If the quenching medium or technique is not suitable for the material, or if it is not applied uniformly, parts of the material may remain soft.

Solutions

- Optimizing the heating process: Ensuring that the material reaches the proper temperature throughout ensures that the desired microstructure forms. This may include using advanced temperature measurement and control equipment.

- Proper selection of quenching media: Different materials require specific quenching media (e.g., oil, water, or polymer solutions) to achieve consistent hardening.

- Uniform quenching: Ensure that the material is uniformly immersed in the quenching medium to avoid soft spots.

5. Cracking

Cracking is a critical defect that occurs when a material fractures during heat treatment. It can occur immediately after the process or as a result of thermal stresses during heating and cooling. Cracking significantly compromises the structural integrity of the material and can lead to failure in service.

Causes

- Thermal stresses: Rapid heating and cooling can cause internal stresses within the material, leading to crack formation.

- Inaccurate cooling rates: Thermal shock brought on by rapid quenching or uneven cooling might result in cracks.

- Internal defects: Materials with pre-existing flaws or inclusions may develop cracks under thermal stress.

Solutions

- Gradual and controlled cooling: To minimize thermal shock, controlled cooling rates should be employed. Slow cooling during quenching and post-cooling can prevent cracking.

- Preheating to avoid thermal shock: Preheating materials before applying heat treatment helps to reduce temperature gradients and internal stresses, minimizing the risk of cracking.

- Stress-relieving treatments: Post-treatment stress relief, such as annealing, can reduce internal stresses, making the material less prone to cracking.

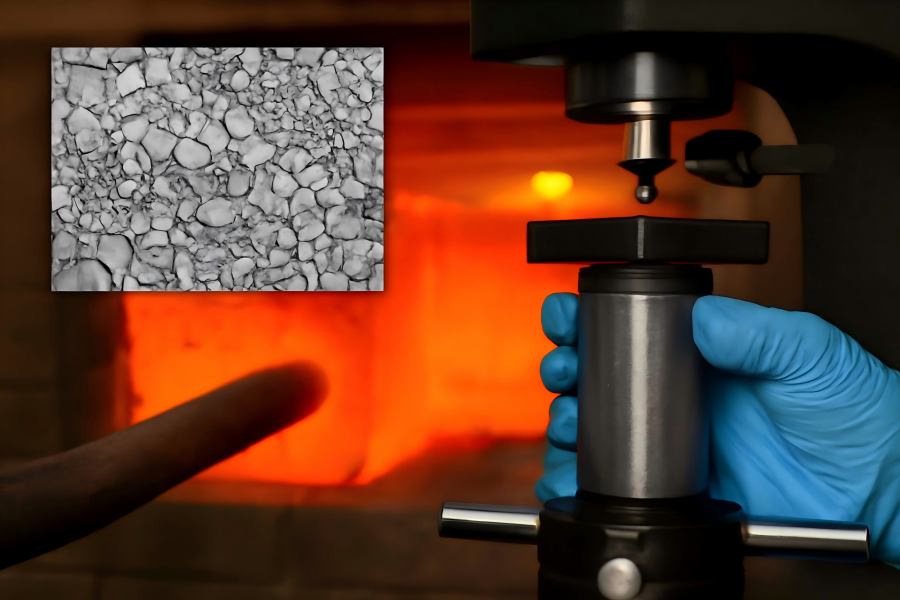

6. Improper Microstructure

The mechanical properties of a material are greatly influenced by its microstructure. If the heat treatment process is not controlled correctly, the desired microstructure may not form, resulting in poor performance characteristics like low strength, hardness, or toughness.

Causes

- Incorrect time-temperature combinations: If the time or temperature parameters are not correctly set, the material may not undergo the correct transformations, leading to a suboptimal microstructure.

- Over or under-quenched materials: If the material is quenched too quickly or too slowly, its microstructure may be incomplete or improperly formed.

Solutions

- Correcting time-temperature cycles: Different materials require specific time-temperature combinations to achieve the desired microstructure. Accurate control and monitoring of these cycles are crucial.

- Regular metallurgical analysis: Continuous metallurgical analysis during the heat treatment process can ensure that the microstructure is correct. This may include using tools like microscopy or hardness testing to monitor progress.

- Use of controlled cooling rates: Using a controlled cooling process during quenching will help ensure the desired microstructure forms evenly throughout the material.