Forged wheels are a cornerstone in high-performance industries, particularly in automotive, aerospace, and motorsports. They are the perfect option for high-end applications because of their strength, durability, and lightweight construction.

However, even the toughest forged wheels are susceptible to damage, whether from road debris, impacts, or general wear.

While the allure of repairing a forged wheel may be tempting, it’s crucial to understand the limits of such repairs and when it’s better to replace a damaged wheel.

What Are Forged Wheels?

Forged wheels are created by heating a solid metal billet and using a hydraulic press or hammer to form it under high pressure. Compared to cast wheels, which are made by pouring molten metal into molds, this results in a wheel that is much stronger and more durable.

Key Benefits of Forged Wheels:

- Strength: Forged wheels are up to 30% stronger than cast wheels due to the grain structure aligned by the forging process. This allows them to endure higher impacts without failure.

- Lightweight: The process reduces the amount of material used, making forged wheels lighter than their cast counterparts. This reduces unsprung weight, improving performance, handling, and fuel efficiency.

- Performance: Forged wheels are perfect for high-performance applications like luxury cars and motorsports because of their increased strength and decreased weight.

- Durability: Forged wheels are more resilient to wear and tear and are less likely to crack or bend under typical driving circumstances.

These benefits, however, have a larger cost. Despite their exceptional properties, forged wheels are not impervious to damage and may require repair after significant impacts or prolonged use.

When Do Forged Wheels Need Repair?

Forged wheels are generally more resilient than cast wheels, but like any mechanical part, they are not immune to damage. Repairs may be necessary for a number of reasons, such as:

Common Issues Requiring Repair:

- Cracks: One of the most critical forms of damage, cracks can form after a wheel is subjected to a hard impact, such as hitting a pothole or curb.

- Bending: Forged wheels, while more resistant to bending, can still become misshapen under extreme conditions, such as a collision or high-speed impact.

- Dents and Scratches: While these don’t always compromise the structural integrity of the wheel, they can affect aesthetics and sometimes, wheel performance.

- Corrosion: Exposure to harsh environmental conditions can lead to corrosion, particularly in areas where protective coatings are scratched or damaged.

Signs That a Forged Wheel Needs Repair:

- Visible Cracks: Cracks on the surface or in the rim are a serious concern, as they can lead to catastrophic failure.

- Bent Rim: A visibly warped or deformed wheel is often an indication that it may need to be straightened or replaced.

- Unusual Vibrations: If a wheel vibrates noticeably while driving, there may be concealed damage causing an imbalance.

- Loss of Air Pressure: A damaged wheel may cause air leaks in the tire, leading to frequent pressure loss.

Limits of Forged Wheel Repair

While repairing forged wheels is possible, it’s not always recommended or feasible, depending on the extent of the damage. Here are the key limitations:

Structural Integrity:

Forged wheels are designed to withstand high levels of stress and force, but repeated damage can compromise their structural integrity. Repairing a heavily cracked or severely bent wheel may not restore it to its original strength, and in some cases, it may even lead to further issues down the road.

Legal and Safety Concerns:

In certain industries, such as motorsports or commercial aviation, safety regulations may prohibit the use of repaired wheels. A compromised wheel could potentially lead to failure, resulting in costly accidents and legal consequences.

When Repair Is Not Advisable:

- Severe Cracks or Breaks: Cracks that extend deeply into the metal may not be safely repairable and can affect the wheel’s ability to carry weight or absorb impact.

- Critical Load-Bearing Areas: Damage to the areas that bear the most weight or stress, such as the inner rim or spoke areas, may render the wheel unsafe for continued use.

- Excessive Wear: Over time, forged wheels can develop stress fractures or fatigue from constant use. In these cases, repair may only offer a temporary solution, and replacing the wheel may be the safer option.

Repair Methods for Forged Wheels

There are several techniques used to repair forged wheels. However, the kind and severity of the damage determine which approach is best.

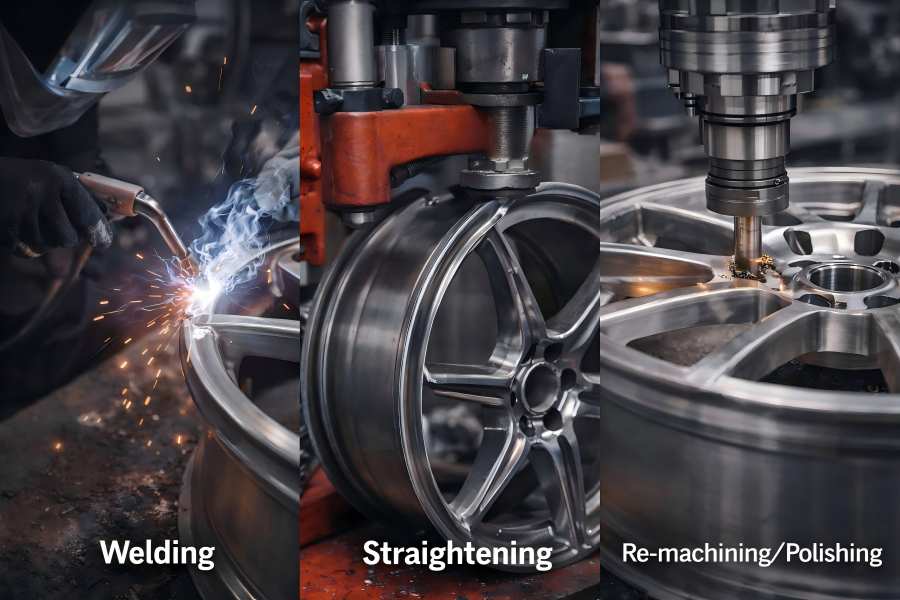

Welding:

One popular technique for fixing cracks is welding. However, welding forged wheels requires precision and care:

- Pros: Welding can restore strength to a cracked wheel by bonding the material together.

- Cons: The heat from welding can alter the wheel’s metal properties, weakening the structureAfter welding, the wheel must be reheated in order to regain its strength.

Straightening:

Bent wheels can often be straightened using specialized machines. The wheel is heated to a certain temperature before pressure is applied to return it to its former shape.

- Pros: Effective for minor bends and dents.

- Cons: Straightening can only be done to a certain extent. Over-straightening or dealing with severe damage can lead to further distortion or cracking.

Re-machining and Polishing:

Surface-level repairs, like polishing out scratches or re-machining the wheel to restore its shape, can be done without compromising the wheel’s strength. These methods primarily address cosmetic damage.

- Pros: Restores the appearance of the wheel without affecting its structural integrity.

- Cons: Only suitable for minor damage. Significant structural issues cannot be resolved with polishing alone.

Heat Treatment:

After welding or straightening, forged wheels may need to undergo heat treatment (tempering) to restore their hardness and strength. Making sure the wheel maintains its durability after repairs requires this crucial step.

- Pros: Necessary for maintaining the wheel’s strength after welding or straightening.

- Cons: Heat treatment requires specialized equipment and should be performed by professionals.

Best Practices for Forged Wheel Repair

To ensure that repairs are both safe and effective, follow these best practices:

Choosing the Right Repair Facility:

It is essential to select a professional repair facility that specializes in forged wheels. Look for facilities with experience, certifications, and specialized equipment for welding, straightening, and heat treating forged wheels.

Inspection and Testing:

Before and after repair, a thorough inspection should be conducted to ensure that the wheel’s structural integrity is intact. Non-destructive testing (NDT), such as ultrasonic or X-ray inspection, can help detect hidden cracks or stress points that are not visible to the naked eye.

Proper Documentation:

For businesses operating in regulated industries, maintaining detailed records of the repair process is crucial. This documentation should include the methods used, materials involved, and test results, ensuring that the repaired wheels meet safety standards.

Cost Considerations

Depending on the kind of damage and the repair technique, the cost of fixing a forged wheel can change. The following table lists some popular repair techniques along with the associated expenses:

| Repair Method | Typical Cost Range | Factors Affecting Cost |

| Welding | $100 – $500 per wheel | Size of crack, type of material, labor costs |

| Straightening | $50 – $200 per wheel | Degree of bend, wheel type, equipment used |

| Re-machining/Polishing | $100 – $300 per wheel | Surface damage, wheel finish, machine time |

| Heat Treatment | $150 – $400 per wheel | Wheel size, complexity of repair, furnace costs |

Repair vs. Replacement:

While repairing forged wheels is often cheaper than replacing them entirely, the price of repairs can quickly add up, especially if multiple wheels are damaged. It may be more cost-effective in the long run to replace heavily damaged wheels, particularly if they have already been repaired multiple times.

Alternatives to Repair

In some cases, replacing a forged wheel may be a better option than repairing it. This is particularly true for:

- Severely damaged wheels that cannot be safely repaired.

- Wheels that have already undergone multiple repairs, as their structural integrity may no longer be reliable.

- Outdated or hard-to-find models, where repairs may not restore the wheel to its original performance.

Benefits of Replacement:

- Guaranteed Performance: A new wheel offers peace of mind and ensures that the vehicle or equipment will perform at its best.

- Long-Term Cost Savings: By replacing a damaged wheel instead of repairing it repeatedly, businesses can avoid ongoing repair costs and potential failures.