Forged flanges are high-strength piping connectors machined from solid forgings. Compared with cast or fabricated flanges, they offer superior dimensional accuracy, toughness, and reliability under high pressure and temperature.

Key flange standards such as ASME B16.5/B16.47 (US) and EN1092-1 (Europe) specify pressure classes, face types, dimensions, and materials for forging-grade flanges.

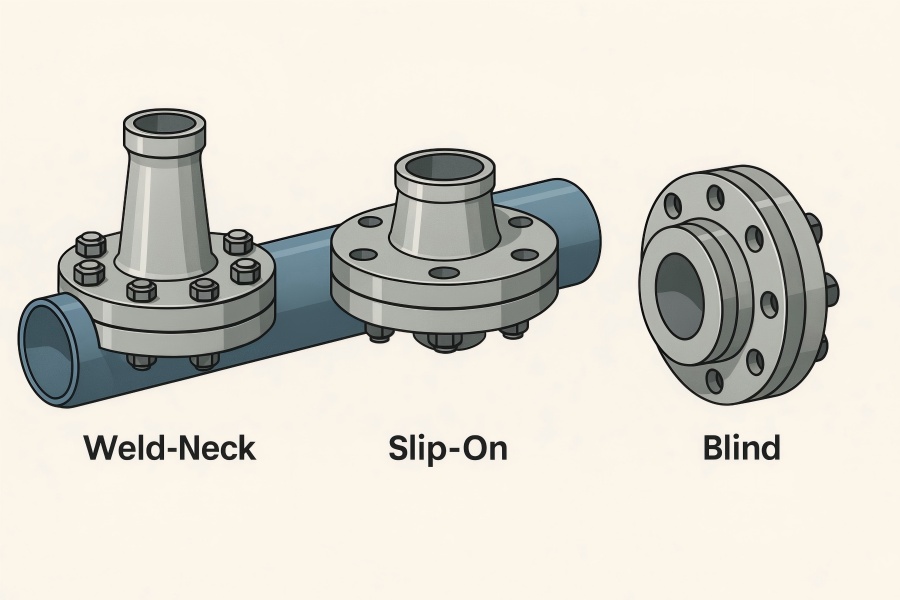

Within forged flanges, weld-neck, slip-on, and Blind are three widely used styles, each tailored for specific service environments.

Weld-Neck Flange

Often referred to as high-hub or tapered-hub flanges, weld-neck flanges have a long, tapered hub that is intended for direct butt welding to a pipe. They are typically machined from forged steel for maximum strength.

| Pros | Cons |

| Excellent mechanical strength | Higher cost and weight |

| Suitable for high pressure/temp | Complex welding and installation |

| Very low leakage risk | Requires tighter tolerances |

Pressure & Temperature Performance

High-pressure, high-temperature, and high-stress applications are ideal for this kind. Welding distributes stresses gradually into the pipe body, minimizing stress concentration. These flanges have been used successfully at pressures up to 5,000 psi.

Specifications & Standards

Covered under ASME B16.5 and B16.47, weld‑neck flanges are offered in pressure classes from 150 through 2500 (ASME) or PN ratings in EN 1092‑1. Face types include raised‑face, flat‑face, tongue‑and‑groove, and ring-joint versions, depending on application needs.

Typical Applications

- Petrochemical, oil & gas pipelines.

- Power generation and high-temperature steam systems.

- Cryogenic lines.

- Nuclear and process industries, where robustness and leak-tightness are critical.

Slip-on Flange

Slip-on flanges are slipped over the pipe end, then fillet-welded on both inside and outside surfaces. They have a straight-through bore and are significantly easier to align in fabrication settings.

| Pros | Cons |

| Lower cost and weight | Lower pressure/temperature capability |

| Easy to align by sliding over the pipe | A fillet weld is less robust than a butt weld |

| Good for field installation | Slight restriction in bore continuity |

Pressure & Temperature Performance

While they offer lower resistance than weld-neck flanges, slip-on flanges are suitable for moderate pressure and temperature service, commonly up to Class 300 or 600, depending on material.

Cost & Installation

They are typically less expensive than weld-neck types in both forging and installation costs, particularly in lower-pressure or non-critical applications. Alignment and welding are simpler, reducing fabrication time.

Typical Applications

- General low-to-medium pressure piping.

- HVAC systems, water distribution.

- Chemical processing where speed and economy matter.

Blind Flange

To seal the end of a vessel or piping system, a blind flange is a solid disk that slides over the pipe bore and is fastened to a matching flange. It is also machined from forging to the same specifications as other pressure-class flanges.

| Pros | Cons |

| Maximum sealing capability | No flow path (cannot pass fluids) |

| Handles high pressure and temperature | Heavy and bulky |

| Useful for testing and maintenance | Requires full bolt circle for strength |

Function & Use

Blind flanges serve two primary roles:

- Permanent end closure (e.g., sealing line ends or tank openings).

- Test point—used during hydrostatic testing or inspection when removal exposes the piping bore.

Design Considerations

Because blind flanges are full-cover disks, they need to withstand the full internal pressure of the system. This results in high bolt loads and torque requirements, especially in higher-pressure ratings.

Applications

- Pipe end caps (permanent or temporary).

- Pressure testing access points in process plants.

- Equipment nozzle covers and isolation points.

Comparative Analysis

| Feature | Weld-Neck | Slip-On | Blind |

| Material & Fabrication | Forged, butt-welded, high precision | Forged, fillet welded, easier fit | Forged solid disc |

| Pressure/Temp Range | Very high (up to ~5,000 psi) | Moderate (Class 150–600 typical) | Full pressure, bolt-loaded |

| Stress Distribution | Excellent via tapered hub | Lower stress class | Bolt stress only |

| Alignment & Installation | Requires alignment & precision | Easy alignment | Simple placement |

| Cost | Highest among the three | Lowest | Moderate (depends on rating/material) |

| Typical Use Cases | Critical process lines | Economic routing lines | Purging, testing, system closing |

Material Considerations & Standards

Forged flanges typically use materials per ASME SA-105 (carbon steel), SA-182 (alloy, stainless), or equivalent EN grade steels. Material choice dictates compatible temperature and pressure ratings under ASME B16.5/B16.47 frameworks.

Face types vary: raised-face for general service, flat-face when mating with non-raised face (often for safety), tongue-and-groove or ring-joint sealing for high integrity in pressure-critical or steam systems.

Selection Guidelines & Engineering Considerations

When selecting between weld-neck, slip-on, or blind forged flanges, several engineering and practical factors must be evaluated to ensure system integrity, cost-efficiency, and long-term performance:

- Pressure class and safety margins: For high-pressure pipelines or systems operating near design limits, weld-neck flanges are the preferred choice due to their superior stress distribution and structural strength.

- Temperature extremes: In environments involving very high temperatures (e.g., steam lines) or cryogenic conditions (e.g., LNG systems), weld-neck flanges perform best thanks to their seamless connection and resistance to thermal expansion stress.

- System criticality: For critical service lines, such as those transporting hazardous fluids or gases, weld-neck flanges offer higher reliability and reduced risk of leakage, making them ideal for mission-critical applications.

- Installation environment: In tight or restricted spaces, where precise alignment is difficult and welding access is limited, slip-on flanges provide easier installation and alignment, especially during retrofits or prefabricated assemblies.

- Future access or testing needs: Blind flanges are essential when periodic maintenance, inspection, or pressure testing is required. They allow easy system isolation without requiring major disassembly or cutting into the pipeline.

- Cost vs. performance balance: In non-critical, low-pressure systems, slip-on flanges often provide an economical solution with acceptable performance, especially where ease of installation and lower upfront cost are priorities.

Proper flange selection ensures not only compliance with ASME/EN standards but also optimal lifecycle performance under the intended operating conditions.

Welding Practices & Quality Assurance

- Weld-Neck flanges require full penetration butt welds, typically verified by non-destructive testing (NDT) like radiography or ultrasonic inspection.

- Slip-On flanges use fillet welds both inside and outside; acceptable for lower-risk applications but still require visual and/or NDT inspection.

- Blind flange bolting must conform to torque and gasket specifications per ASME B16.5; flange bolts must be compatible with gasket type (e.g., spiral wound, ring joint).

Materials and welding procedures must comply with ASME B31.3 (Process Piping) or B31.1 (Power Piping), depending on industry, including preheat, post-weld heat treatment (PWHT), and compatibility with piping material.

Practical Case Studies

Petrochemical Refinery High-Pressure Feed Header

Weld-neck flanges join Class 1500 alloy steel pipes at 900 °F, offering exceptional resistance to thermal stress, ensuring tight sealing, and maintaining long-term reliability in continuous, high-pressure hydrocarbon processing operations.

Municipal Water Treatment Plant

Slip-on flanges are installed on Class 150 mild-steel pipelines, allowing for fast alignment and welding. Perfect for low-pressure, non-critical systems where public water distribution requires rapid installation and cost effectiveness.

Shutdown Port on Pressure Vessel

Blind flanges act as temporary closures on vessel nozzles, enabling pressure testing and internal inspections. They eliminate the need for permanent welding and offer simple access during maintenance or future pipeline extensions.

Summary & Best Practices

- Weld-Neck = best-in-class strength, stress distribution, and high-integrity sealing, ideal for critical, high-pressure/temperature applications.

- Slip-On = economical and easy to install, suitable for moderate service conditions, maintenance zones, or cost-sensitive lines.

- Blind = essential for sealing off pipeline ends and providing access/test points, with full pressure load-bearing capabilities.

Recommended selection workflow:

- Define the system pressure class and temperature.

- Assess criticality and regulatory/engineering codes.

- Choose flange type balancing performance, cost, and installation feasibility.

- Specify material and face type per applicable standard.

- Make sure that the bolting, welding, and inspection processes follow safety regulations and industry best practices.