Forged Mill Wheel

- Available material choices: Carbon steel, alloy steel, stainless steel, and nickel alloys.

- Machining Accuracy: Tolerance up to ±0.02 mm; surface roughness Ra ≤ 1.6 μm.

- Load Capacity: Suitable for heavy-duty rail applications, up to 30 tons per wheel.

- Performance: High fatigue resistance and dimensional stability.

- Certification: ISO9001, PED, SGS.

- Delivery Time: 30–45 days standard; 15–30 days for urgent orders.

Technical Specifications

| Parameter | Specification |

| Product Name | Forged Mill Wheel |

| Material Options | Nickel Alloys / Carbon Steel / Alloy Steel / Stainless Steel |

| Outer Diameter Range | 500 mm – 1300 mm (customizable up to 1600 mm) |

| Rim Width Range | 90 mm – 180 mm |

| Bore Diameter Range | 100 mm – 400 mm |

| Unit Weight Range | 200 kg – 1500 kg per wheel |

| Forging Type | Open Die / Die Forging |

| Machining Tolerance | ±0.02 mm |

| Surface Finish | Ra ≤ 1.6 μm |

| Heat Treatment | Quenching & Tempering / Normalising / Stress Relieving |

| Inspection | UT / MT / Hardness / Dimensional / Mechanical |

| Certification | ISO9001 / PED / SGS |

| Delivery Time | 15–30 Days (Urgent) / 30–45 Days (Normal) |

| Packaging | Steel Frame / Wooden Case / As per Client Requirement |

Product Advantages

- High Dimensional Accuracy: Tolerance control ensures perfect axle fit and smooth rail rolling.

- High Tensile Strength: Forged structure withstands repeated stress cycles and heavy loads.

- Superior Fatigue Resistance: Ideal for high-speed and long-service rail systems.

- Excellent Toughness: Maintains integrity under impact and dynamic loads.

- Thermal Stability: Performs consistently under braking heat and friction.

- Corrosion Resistance: Alloy and stainless grades resist moisture and oxidation.

Customization & OEM Service

- Custom Dimensions: Wheel size, bore, and rim thickness are manufactured per drawing.

- Material Selection: Options for carbon, alloy, or stainless steel depending on rail type.

- Surface Treatment: Polishing, rust-proof coating, or heat-resistant finishing.

- OEM Branding: Engraving or marking available for rail system suppliers.

- Sample Service: MOQ = 1 piece for prototype approval.

Application Fields

- Railway Passenger Coaches: Durable, low-vibration wheelsets for smooth operation.

- Freight Wagons: Heavy-load support with high abrasion resistance.

- Locomotives: High torque and traction strength under dynamic stress.

- Metro Cars: Noise reduction and long wear life for urban systems.

- Light Rail Vehicles: Balanced design for lightweight, high-speed use.

Manufacturing Capabilities

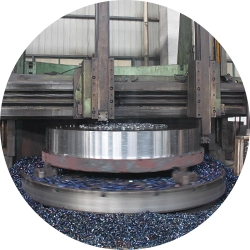

Forging Facilities

- 6300T / 3150T / 2000T free hydraulic presses.

- 5T, 3T, 2T, 1T, 750kg, 560kg electro-hydraulic hammers.

Heating Treatment Facilities

- RTX-9 series trolley furnaces in multiple sizes (5.5–8 m chamber length).

- RJ-9-850KW vertical furnace with 15 m depth.

- RTX-12-350KW high-temperature trolley furnace.

Machining Facilities

- CNC machines (max 32-ton load).

- Heavy-duty lathes and vertical mills (up to 70 tons).

- Gantry milling machines, deep-hole boring machines, grinding and turning centers.

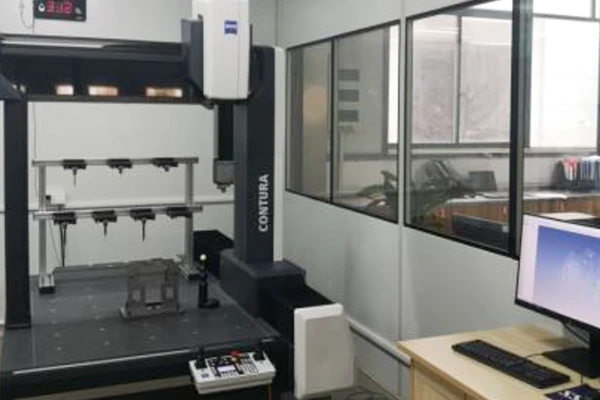

Testing & Quality Control

- Spectrum analysis for chemical composition.

- Ultrasonic, non-destructive, and metallographic testing.

- Mechanical property test machines for yield, tensile, hardness.

Production Process

- Raw Material Selection: Use first-grade ingot steel, inspect chemical composition.

- Forging: Heat to precise temperature, perform open die or die forging.

- Heat Treatment: Quenching, tempering, or normalizing to meet mechanical targets.

- Machining: CNC turning, boring, milling, grinding, and drilling to precision ±0.01 mm.

- Inspection: Each shaft tested via 100% ultrasonic, hardness, and tensile checks.

- Packaging & Delivery: Anti-corrosion coating, safe transport packaging, global logistics support.

Additional Value-added Services

- Quench-and-temper heat treating

- Rough and finish turning

- Ultrasonic and mechanical testing

- Dimensional inspection reports

- Customized design and programming support

Quality Assurance

- Each forging carries a test bar for mechanical testing.

- 100% ultrasonic and visual inspection before shipment.

- Hardness, tensile, and metallographic verification.

- Compliance with ASTM, DIN, GB, and EN standards.

Why Choose Boberry

Integrated Production

Complete forging-to-machining production line ensures precision and fast delivery.

Advanced Equipment

Heavy-duty forging presses and CNC systems handle large, complex mechanical component geometries.

Certified Assurance

Certified production with ISO9001, PED, SGS compliance and global OEM support.

Logistics & Delivery

Lead Time: 15–30 days (urgent) / 30–45 days (normal).

Monthly Capacity: 500–1000 tons.

Packing: Wooden crates, steel frames, or per client request.

Shipment: By Sea (recommended, saves cost for forging parts) / By Air (fast but expensive).

Payment Terms: 30% deposit with balance via B/L copy; or 100% L/C at sight.

Delivery Terms: FOB, CIF, CNF.

Monthly Capacity: 500–1000 tons.

Packing: Wooden crates, steel frames, or per client request.

Shipment: By Sea (recommended, saves cost for forging parts) / By Air (fast but expensive).

Payment Terms: 30% deposit with balance via B/L copy; or 100% L/C at sight.

Delivery Terms: FOB, CIF, CNF.