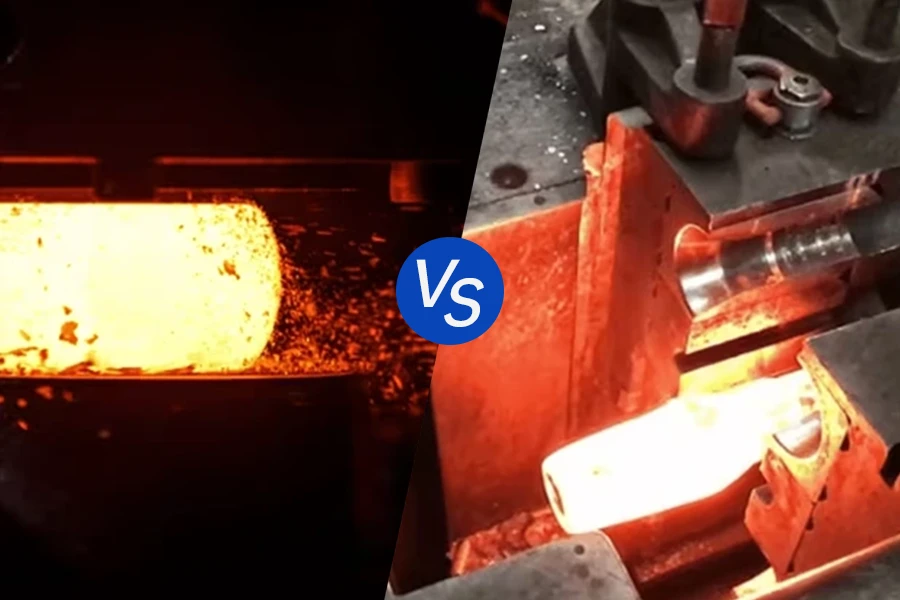

One important technique for shaping metal that has fueled industrial development for ages is forging. The two most popular forging methods are drop forging and upset forging, among others. The cost, production efficiency, and part performance can all be significantly impacted by the process selection.

Introduction to Forging Techniques

Forging involves the deformation of metal under high pressure, typically using dies, hammers, or presses to shape the material. The result is a component with enhanced strength, fatigue resistance, and an improved grain structure, making forged parts highly desirable in critical applications.

The two major forging types, drop forging and upset forging, differ in how force is applied and how metal flows. The ideal parts for drop forging are those with complicated features and complex geometry. Upset forging, on the other hand, is commonly used for enlarging sections of round bars, especially at the ends, such as forming bolt heads or flanges.

Both techniques ensure metallurgical advantages over casting or machining, with better directional strength and material integrity.

What Is Drop Forging?

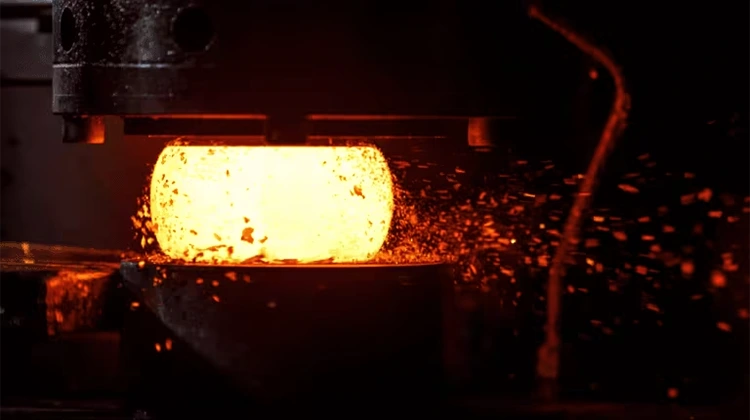

In drop forging, a hot metal blank is sandwiched between two dies and formed by pressing or high-impact hammering. The hammer “drops” onto the workpiece, hence the process’s name.

There are two primary forms:

- Open-die drop forging allows the material to flow freely and is ideal for large, simple parts. However, it requires skilled operation and has lower dimensional accuracy.

- Closed-die (impression-die) forging confines the metal within a die cavity, enabling the production of complex and precise parts. Extra material is squeezed out as flash and then cut off.

How Drop Forging Works:

- The forging temperature of the metal is raised.

- It is positioned on the bottom die.

- The upper die repeatedly strikes the workpiece.

- Metal flows into the die cavity, and flash is expelled.

- The part is then trimmed, cooled, and finished.

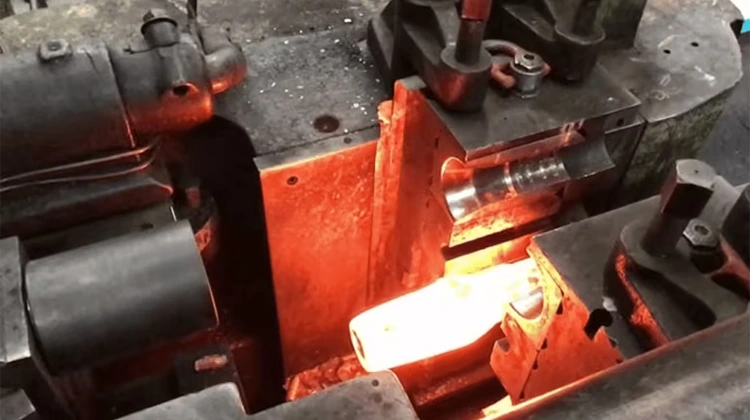

What Is Upset Forging?

Upset forging is a type of forging that increases the diameter of a section of a bar by compressing its length. It is performed using horizontal forging machines known as upsetters and is particularly efficient for producing parts like bolts, fasteners, and shafts.

How Upset Forging Works:

- A cylindrical bar is partially or fully heated.

- The heated portion is inserted into a die and clamped in place.

- A ram compresses the bar along its axis.

- The material expands outward, creating a head or flange.

- The part is cooled, trimmed, and inspected.

Key Process Differences

| Feature | Drop Forging | Upset Forging |

| Force Direction | Vertical hammering | Horizontal axial compression |

| Material Flow | Multi-directional | Axial to radial expansion |

| Workpiece Form | Precut blanks | Round bars |

| Typical Output | Complex 3D geometries | Heads, flanges, shaft enlargements |

| Flash Generation | Yes (especially closed-die) | Often flashless |

These differences influence part design flexibility, required equipment, and production strategy.

Material Considerations

Both forging methods can process a range of metals, but some are better suited for specific techniques:

- Drop forging can handle tough materials such as carbon steel, alloy steel, stainless steel, aluminum, brass, and titanium. It accommodates complex shapes and strong mechanical properties.

- Upset forging works best with ductile metals like low-carbon steel, aluminum, and copper, which can deform without cracking during radial expansion.

Choosing the correct material ensures successful forming and final part performance.

Part Design and Geometry

Drop Forging:

- Best for parts with intricate shapes and varying cross-sections.

- Can form ribs, holes, bosses, and detailed contours.

- Ideal when parts require multi-directional grain flow.

Upset Forging:

- Suited for symmetric, cylindrical parts.

- Ideal for forming bolt heads, pipe flanges, and stepped shafts.

- Limited to axial deformation.

Engineers must assess shape complexity and performance demands when choosing between the two.

Strength and Mechanical Properties

Both forging methods improve part strength due to grain refinement and directional grain flow.

- Drop forging aligns grains along complex contours, boosting impact strength and fatigue resistance.

- Upset forging aligns grains along the axis, resulting in excellent tensile strength and torsional integrity.

Final properties depend on the forging temperature, strain rate, and cooling process.

Production Volume and Cost

| Factor | Drop Forging | Upset Forging |

| Setup Cost | High (custom tooling needed) | Medium (moderate die cost) |

| Cycle Time | Longer (multiple hammer strokes) | Shorter (quick axial compression) |

| Best For | High-volume, complex parts | Medium-volume, standardized parts |

Tip: Use drop forging for high-precision, complex components where tooling cost is amortized over large volumes. Choose upset forging for simpler parts with high repeatability.

Tooling and Equipment Needs

- Drop forging demands large presses, dies, and trimming equipment. The tools are expensive, especially for closed-die operations, and must withstand repetitive impact loads.

- Upset forging requires horizontal upsetters with clamping dies and simpler tooling. Tool wear is less aggressive, and equipment is often more compact.

Manufacturers must weigh equipment investment, maintenance, and tooling life when planning production.

Tolerances and Surface Finish

- Drop forging achieves tight tolerances and near-net shapes, reducing post-processing needs.

- Upset forging produces smoother surfaces on cylindrical parts but may require machining to achieve tight fits.

Surface finish quality also depends on die condition, material, and lubrication practices.

Application Comparison by Industry

| Industry | Drop Forging Applications | Upset Forging Applications |

| Automotive | Crankshafts, connecting rods, gears | Axles, fasteners, shaft ends |

| Aerospace | Turbine blades, landing gear parts | Actuator rods, valve stems |

| Construction | Hooks, shackles, structural tools | Bolts, anchor rods, eye bolts |

| Oil & Gas | Drill collars, clamps | Flanges, couplings |

| Agriculture | Harrow arms, plow blades | Shafts, mounting bolts |

This comparison shows how each forging method aligns with specific part types and industry requirements.

Environmental and Energy Efficiency

Forging is generally more sustainable than machining, primarily due to its lower material waste and higher material utilization. However, efficiency varies between forging methods:

- Drop forging produces flash, excess material squeezed out during die closure, which must be trimmed off. This not only increases material waste but also adds to the energy and labor required for flash removal and recycling.

- Upset forging is typically a flashless process, meaning it uses nearly 100% of the material with minimal or no waste. This improves material efficiency and reduces post-processing requirements.

In terms of energy use, upset forging is generally more efficient. Its shorter cycle times and simpler deformation steps mean less energy is consumed per part, making it a preferred choice for high-volume, standardized production.

Choosing Based on Product Lifecycle

When selecting a forging method, it’s important to consider the long-term performance and durability of the part:

- Drop forging is ideal for components exposed to high-impact forces or repeated stress cycles. It enhances fatigue resistance and structural integrity, making it suitable for mission-critical parts in automotive, aerospace, and heavy machinery.

- Upset forging offers excellent axial strength and is well-suited for simpler parts like bolts, shafts, and flanges. It’s effective for components that are regularly replaced or used in less demanding environments.

If failure or replacement is difficult and costly, drop forging is the safer long-term investment due to its superior performance and reliability.

Case Studies: Drop vs. Upset Forging

Case Study 1: Automotive Crankshaft

Chosen Method: Drop Forging

Reason: The crankshaft operates under continuous rotational and bending loads, making strength and fatigue resistance critical. Drop forging allows for precise grain flow that follows the complex shape of the crankshaft, enhancing durability and performance under cyclic stresses.

Case Study 2: Industrial Bolt Production

Chosen Method: Upset Forging

Reason: Bolts require uniform dimensions and strong axial integrity. Upset forging enables efficient, high-speed production of symmetrical heads on bar stock with minimal waste. Its flashless process ensures material savings and consistent mechanical properties along the bolt shaft.

Case Study 3: Aircraft Landing Gear Arm

Chosen Method: Drop Forging

Reason: The landing gear arm must handle high-impact forces during aircraft takeoff and landing. Drop forging offers the ability to shape precise, load-bearing geometries while aligning the internal grain structure for superior toughness and resistance to failure.

Summary Table

| Criteria | Drop Forging | Upset Forging |

| Part Complexity | High | Low to Medium |

| Tolerance Level | Tight | Moderate |

| Flash Production | Yes | Minimal or none |

| Cycle Time | Longer | Shorter |

| Equipment | Vertical hammers/presses | Horizontal upsetters |

| Grain Flow Control | Complex, multi-axial | Axial to radial |

| Ideal for | Irregular, load-bearing parts | Shafts, bolts, flanges |

| Material Efficiency | Medium | High |

| Production Volume | High-volume | Medium to high |