Clamp Pipe Fittings

- Material options: Carbon steel, 304 stainless steel, and 316 stainless steel suitable for use in highly corrosive environments.

- Angle and style: Special angles, swivel joints, and multi-outlet connectors designed to project requirements.

- Reusable design: Components can be repositioned or reused when structures are modified or extended.

- Versatile compatibility: Suited to common pipe diameters used in handrails, guardrails, shelving systems, and structural support frames.

- Quick installation: Bolt-on design enables fast assembly without welding, special tools, or hot work permits.

Technical Specifications

| Item | Specification |

| Material | Carbon steel with hot-dip galvanizing or stainless steel 304/316 |

| Pipe diameter range | 21.3 mm – 60.3 mm (¾” – 2″) |

| Wall thickness range | 2.0 mm – 4.0 mm |

| Standard angle options | 90° corner, 45° angle, T-joint, cross joint |

| Finish thickness | Zinc coating ≥ 60 μm (hot-dip galvanized type) |

| Recommended working load* | Up to 1.5 kN per joint (vertical static load) |

| Temperature range | –20 °C to +120 °C (standard carbon steel version) |

| Fasteners | M6–M10 galvanized or stainless steel hex bolts and nuts |

| Compliance | Meets general structural hardware practices per EN / ISO guidelines |

| Packaging | Cartons with inner bags, 20–25 kg per carton |

Applications

- Handrails and guardrails in industrial plants

- Safety barriers and walkways in warehouses

- Display racks and modular shelving systems

- Temporary event structures and exhibition frames

- Outdoor shelters, awnings, and pergola frames

- Pipe-based supports for solar panels or signage

Production Process

Our precision casting production process integrates wax modeling, automated shell making, controlled pouring, heat treatment, and machining to ensure dimensional accuracy, integrity, and quality.

Wax Injection

Shell Making

Shell Baking

Pouring

Shot Blasting

Heat Treatment

Machining

Inspection

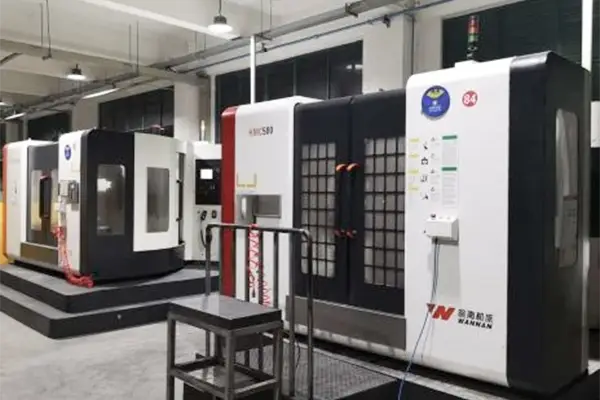

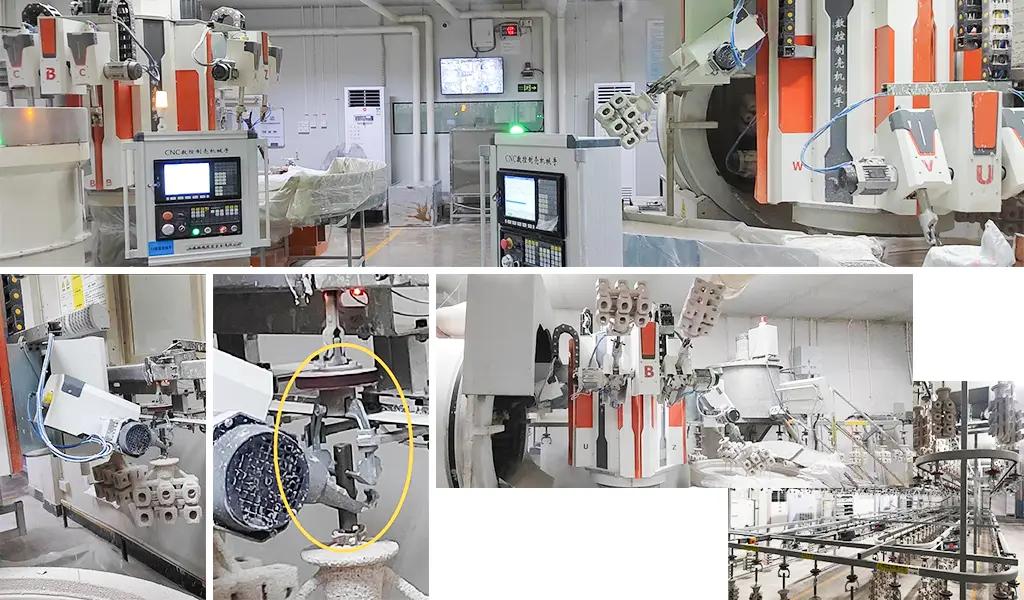

Advanced Workshop

Advanced workshops include wax model production, CNC robotic shell making, semi-automatic pouring, baking furnaces, and machining centers supporting automation, efficiency, flexibility, and operations.

Medium Temperature Wax Workshop

Low Temperature Wax Workshop

9-axles CNC Shell-making Robot Arm Workshop

Semi-auto Pouring Machine

Baking Furnace

Horizontal CNC Machining Center

New Shell Making Automation Line

New shell making automation line optimizes reduction processes, improves production efficiency, ensures reliable equipment operation, extends running time, and significantly reduces labor intensity overall.

Shell Making Automation Line No. 01 – Small & Medium Parts

Automated shell making line for small and medium castings improves shell uniformity, reduces manual intervention, and enhances production stability and efficiency.

Shell Making Automation Line No. 02 – Large Parts

Specialized automation line supports large investment castings, handling complex geometries and higher weights while maintaining shell strength and process reliability.

Shell Making Automation Line No. 03 – Investment Casting

Optimized shell making system streamlines reduction processes, improves efficiency, ensures long-term equipment reliability, and significantly reduces labor intensity.

Quality Inspection

Comprehensive quality inspection system covering materials, processes, dimensions, and final products to ensure traceability, consistency, and full compliance with customer specifications.

Zeiss CMM Machine

X-ray Flaw Detector

100T Horizontal Tensile Testing Machine

Rockwell Hardness Standard Machine

Logistics & Delivery

Monthly Capacity: 500–1000 tons.

Packing: Wooden crates, steel frames, or per client request.

Shipment: By Sea (recommended, saves cost for forging parts) / By Air (fast but expensive).

Payment Terms: 30% deposit with balance via B/L copy; or 100% L/C at sight.

Delivery Terms: FOB, CIF, CNF.