Alloy Steel Cast Spare Parts

- Flexible size capability: Dimensions up to 1500 × 1500 × 1500 mm for large or complex spare parts.

- Wide weight range: Investment cast parts from 0.001–99 kg; sand castings from 0.5–500 kg.

- Fine surface finish: Casting roughness can reach Ra1.6–3.2, reducing polishing and finishing workload.

- High-precision machining: Critical dimensions can be finished to ±0.009 mm for accurate assembly.

- Optimized alloy selection: Multiple steel grades (ZG40Mn, ZG35SiMn, ZG55CrMnMo, etc.) chosen according to mechanical and wear requirements.

Technical Specifications

| Item | Details |

| Product Name | Alloy Steel Cast Spare Parts |

| Casting Processes | Investment casting, Sand casting |

| Maximum Dimensions | Approx. 1500 × 1500 × 1500 mm |

| Weight Range – Investment | 0.001–99 kg |

| Weight Range – Sand Casting | 0.5–500 kg |

| Minimum Wall Thickness | About 0.5 mm |

| Casting Surface Roughness | Ra1.6–3.2 (typical); general range up to Ra3.2–6.4 |

| Machining Accuracy | Finished machining tolerance up to ±0.009 mm |

| Main Standards | EN, BS, AISI, ASTM, JIS, GB |

| Typical Alloy Steel Grades | ZG40Mn, ZG40Mn2, ZG50Mn2, ZG20SiMn, ZG35SiMn, ZG35SiMnMo, ZC35CrMnSi, ZG20MnMo, ZG55CrMnMo |

| Smelting Capability | Steel plus nickel, bronze (brass) alloy, aluminium alloy, etc. |

| Supply Capacity | 100–150 tons per month |

| Delivery Time | About 45 days |

Alloy Steel Chemical Composition Table

| TYPE | C | Si | Mn | S | P | Cr | Ni | Mo | Cu |

| ZG40Mn | 0.30–0.45 | 0.30–0.45 | 1.20–1.50 | ≤0.030 | |||||

| ZG40Mn2 | 0.35–0.45 | 0.20–0.40 | 1.60–1.80 | ≤0.030 | |||||

| ZG50Mn2 | 0.45–0.55 | 0.20–0.40 | 1.50–1.80 | ≤0.030 | |||||

| ZG20SiMn | ≤0.23 | ≤0.60 | 1.00–1.50 | ≤0.025 | ≤0.30 | ≤0.40 | ≤0.15 | ||

| ZG35SiMn | 0.30–0.40 | 0.60–0.80 | 1.10–1.40 | ≤0.030 | |||||

| ZG35SiMnMo | 0.32–0.40 | 1.10–1.40 | 1.10–1.40 | ≤0.030 | ≤0.30 | ≤0.30 | 0.20–0.30 | ≤0.30 | |

| ZC35CrMnSi | 0.30–0.40 | 0.50–0.75 | 0.90–1.20 | ≤0.030 | 0.50–0.80 | ||||

| ZG20MnMo | 0.17–0.23 | 0.20–0.40 | 1.10–1.40 | ≤0.030 | ≤0.30 | ≤0.30 | 0.20–0.35 | ≤0.30 | |

| ZG55CrMnMo | 0.50–0.60 | 0.25–0.60 | 1.20–1.60 | ≤0.030 | 0.60–0.90 | ≤0.30 | 0.20–0.30 | ≤0.30 |

Applications

- Marine equipment and offshore structures

- Food processing and packaging machinery

- Mining and mineral processing equipment

- Wind energy and power-generation components

- Fluid industry, pump and valve assemblies

- Metallurgical and heavy industrial machinery

- Garden and outdoor power equipment

Production Process

Our precision casting production process integrates wax modeling, automated shell making, controlled pouring, heat treatment, and machining to ensure dimensional accuracy, integrity, and quality.

Wax Injection

Shell Making

Shell Baking

Pouring

Shot Blasting

Heat Treatment

Machining

Inspection

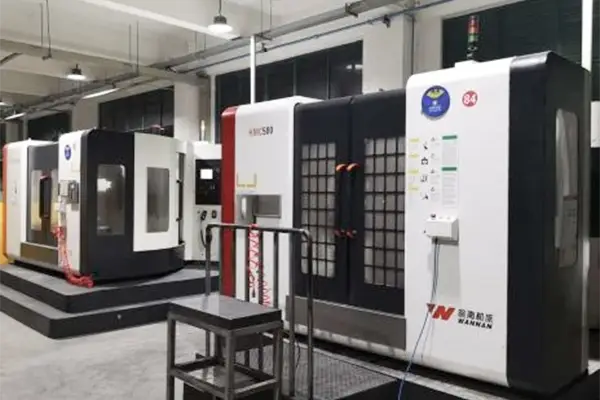

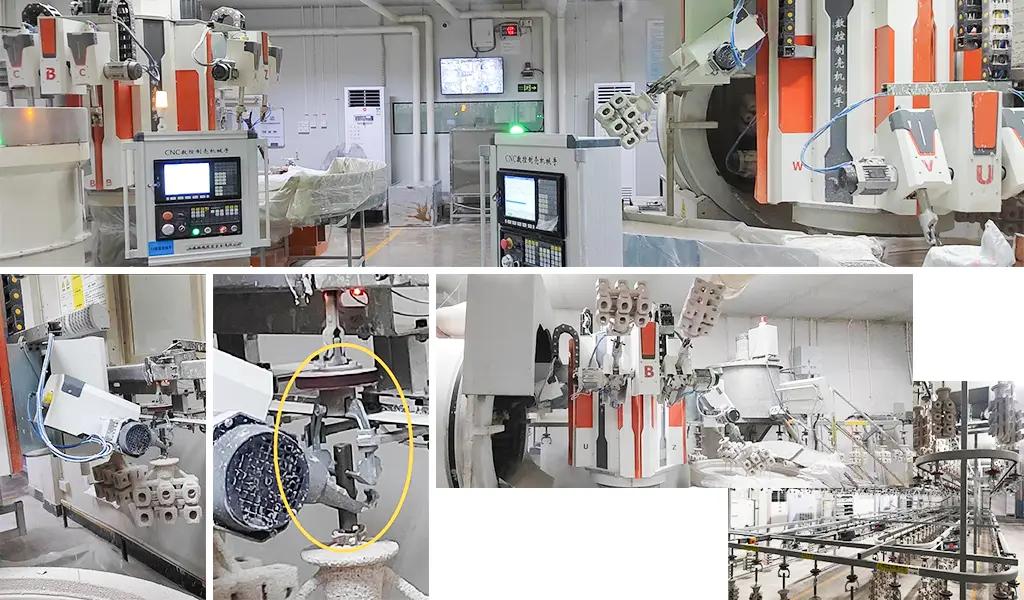

Advanced Workshop

Advanced workshops include wax model production, CNC robotic shell making, semi-automatic pouring, baking furnaces, and machining centers supporting automation, efficiency, flexibility, and operations.

Medium Temperature Wax Workshop

Low Temperature Wax Workshop

9-axles CNC Shell-making Robot Arm Workshop

Semi-auto Pouring Machine

Baking Furnace

Horizontal CNC Machining Center

New Shell Making Automation Line

New shell making automation line optimizes reduction processes, improves production efficiency, ensures reliable equipment operation, extends running time, and significantly reduces labor intensity overall.

Shell Making Automation Line No. 01 – Small & Medium Parts

Automated shell making line for small and medium castings improves shell uniformity, reduces manual intervention, and enhances production stability and efficiency.

Shell Making Automation Line No. 02 – Large Parts

Specialized automation line supports large investment castings, handling complex geometries and higher weights while maintaining shell strength and process reliability.

Shell Making Automation Line No. 03 – Investment Casting

Optimized shell making system streamlines reduction processes, improves efficiency, ensures long-term equipment reliability, and significantly reduces labor intensity.

Quality Inspection

Comprehensive quality inspection system covering materials, processes, dimensions, and final products to ensure traceability, consistency, and full compliance with customer specifications.

Zeiss CMM Machine

X-ray Flaw Detector

100T Horizontal Tensile Testing Machine

Rockwell Hardness Standard Machine

Logistics & Delivery

Monthly Capacity: 500–1000 tons.

Packing: Wooden crates, steel frames, or per client request.

Shipment: By Sea (recommended, saves cost for forging parts) / By Air (fast but expensive).

Payment Terms: 30% deposit with balance via B/L copy; or 100% L/C at sight.

Delivery Terms: FOB, CIF, CNF.