Surface roughness plays a decisive role in determining how metal components perform under stress, friction, and corrosion. In both forging and casting, two of the most widely used metal-forming processes, surface quality directly influences product reliability and service life.

Rough surfaces can accelerate wear, promote crack initiation, and reduce fatigue strength, whereas smoother finishes enhance structural integrity and corrosion resistance. Forged parts, produced through controlled plastic deformation, usually exhibit better surface uniformity compared to cast parts formed by pouring molten metal into a mold.

Understanding Surface Roughness

Surface roughness quantifies the texture of a surface by measuring deviations in the micro-profile. The average height variation from a mean line is represented by the most widely used measure, Ra (Arithmetic Mean Roughness). Other metrics include Rz (Maximum Height of the Profile) and Rt (Total Height of Roughness Profile).

These parameters reveal how microscopic peaks and valleys affect part interaction during operation. High roughness leads to greater friction and localized stress, while low roughness enhances fatigue resistance and sealing performance.

| Parameter | Definition | Typical Unit | Description |

| Ra | Average roughness | µm | Mean deviation of surface profile |

| Rz | Mean peak-to-valley height | µm | Average of 5 highest peaks and valleys |

| Rt | Total height | µm | Distance between highest peak and lowest valley |

Measurement techniques vary — contact profilometers use stylus tracing, while optical interferometers and laser scanners capture 3D topography for precision inspection.

Surface Roughness in Forging Processes

Forging refines the metal’s grain structure through plastic deformation, producing dense and uniform parts. Die quality, lubrication, and forging temperature are some of the variables that affect the surface finish.

- Die condition: A polished die yields smoother surfaces.

- Lubrication: Reduces friction and surface tearing.

- Temperature control: Prevents oxidation and scale formation.

For example, hot-forged steel crankshafts typically exhibit Ra values between 0.4–1.6 µm, whereas cold-forged components can achieve Ra < 0.2 µm after finishing.

Forged surfaces have superior fatigue strength because the compressive stresses introduced during forging minimize crack initiation at surface irregularities.

Surface Roughness in Casting Processes

Casting inherently produces higher surface roughness due to the nature of molds and solidification. Sand casting results in coarse surfaces (Ra: 3.2–12.5 µm), while die casting and investment casting achieve finer finishes.

Key factors affecting roughness include:

- Mold material and finish: Sand, ceramic, or metal molds have varying texture profiles.

- Cooling rate: Faster solidification improves smoothness but can trap defects.

- Mold coating: Creates a barrier to reduce adhesion and surface irregularities.

Post-casting treatments like grinding, shot blasting, or polishing are typically required to enhance the surface and reduce Ra to 0.8–3.2 µm for critical components.

Comparing Forged vs. Cast Surfaces

| Property | Forged Metal Parts | Cast Metal Parts | Durability Impact |

| Typical Ra (µm) | 0.2–1.6 | 1.6–6.3 | Smoother surfaces improve fatigue life |

| Defect Density | Very low | Moderate–high (porosity, inclusions) | Forged surfaces resist crack initiation |

| Grain Structure | Continuous & aligned | Random & coarse | Forged parts offer higher strength |

| Post-finishing | Moderate need | Extensive | Adds cost and time for castings |

Forged components usually have tighter surface control, while cast components require additional finishing steps to achieve comparable durability. The difference becomes critical in high-load applications like aerospace and automotive systems, where micro-surface imperfections act as stress concentrators.

Surface Roughness and Fatigue Resistance

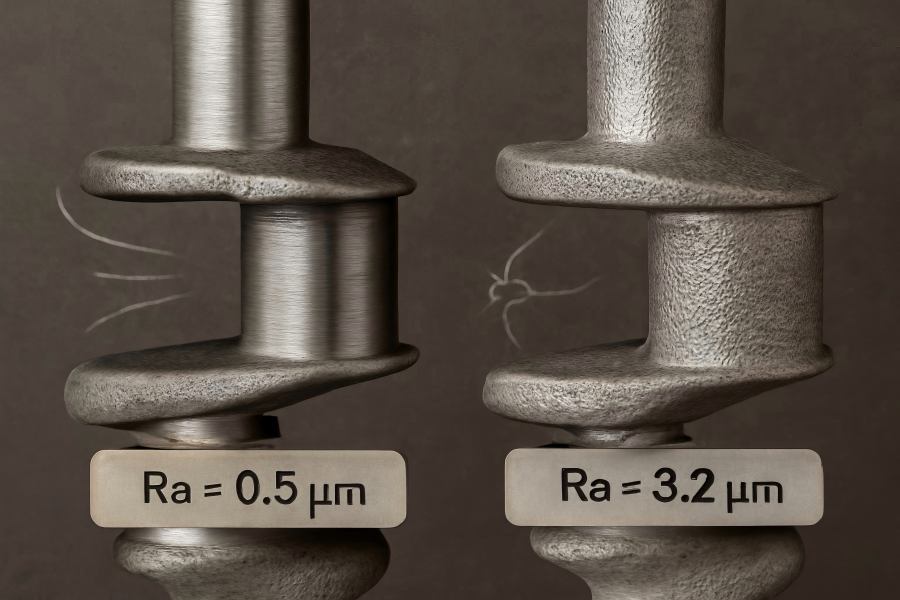

Under cyclic loading, surface imperfections act as sites for the initiation of cracks. The higher the surface roughness, the shorter the fatigue life due to stress concentration at the peaks. Forged parts, with smoother surfaces, demonstrate significantly greater endurance.

For instance:

- A forged crankshaft (Ra ≈ 0.8 µm) can sustain over 10⁷ load cycles.

- A comparable cast crankshaft (Ra ≈ 3.2 µm) may fail after 10⁵–10⁶ cycles.

Empirical Relation Example:

Fatigue strength decreases approximately 10–15% for every 1 µm increase in Ra (depending on material and loading conditions).

Surface Roughness and Wear Resistance

Wear is the result of two surfaces rolling or sliding against one another. High surface peaks increase friction and abrasive wear, while smoother surfaces promote fluid film lubrication.

Case Example:

In hydraulic systems, forged steel piston rods polished to Ra ≤ 0.2 µm last up to 3× longer than unpolished or roughly cast ones. Improved surface finish maintains the oil film, preventing direct metal-to-metal contact.

Surface Roughness and Corrosion Resistance

Surface roughness influences corrosion initiation by determining the area of exposure and micro-crevice formation. Rough cast surfaces trap contaminants and moisture, accelerating pitting and crevice corrosion.

| Metal Type | Process | Surface Roughness (Ra µm) | Corrosion Resistance (Relative Index) |

| Stainless Steel | Forged | 0.4 | Excellent (Index 1.0) |

| Stainless Steel | Cast | 3.2 | Moderate (Index 0.7) |

| Aluminum Alloy | Die Cast | 1.6 | Good (Index 0.8) |

| Aluminum Alloy | Sand Cast | 6.3 | Poor (Index 0.5) |

Polishing, coating, and passivation treatments are often applied to reduce roughness and improve corrosion resistance in harsh environments (marine, chemical, or humid conditions).

Testing and Measuring Durability

Durability evaluation combines surface measurement with mechanical testing:

- Fatigue testing: Measures endurance limit versus surface roughness.

- Wear testing: Simulates sliding contact conditions.

- Corrosion tests: Salt spray or immersion tests to assess pit initiation.

Example:

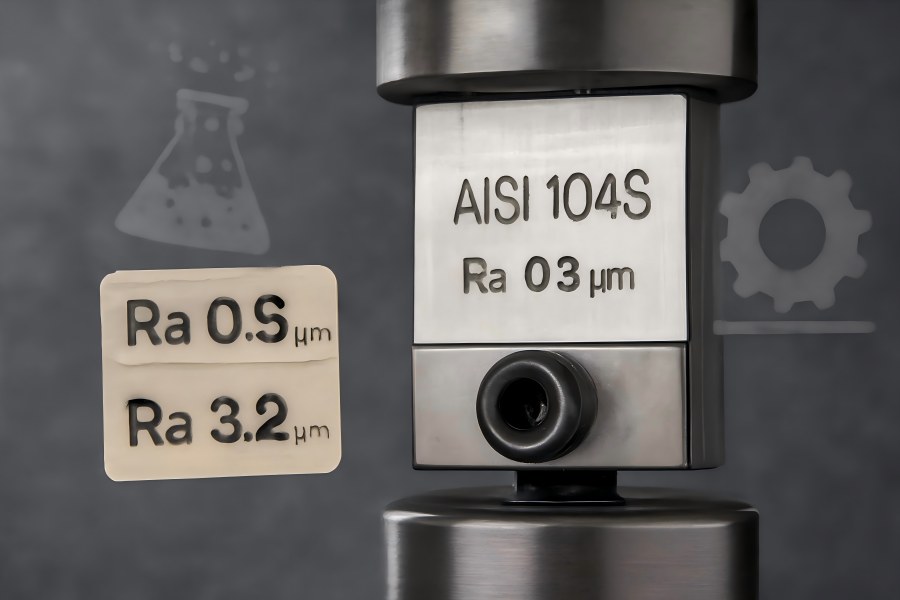

A test on AISI 1045 steel revealed that samples with Ra = 0.8 µm exhibited 40% higher fatigue strength compared to those with Ra = 3.2 µm, under identical cyclic loading conditions.

Surface Finishing Techniques for Durability Enhancement

To enhance part life, several finishing methods are used:

| Technique | Process Description | Typical Ra Achieved (µm) | Application |

| Grinding | Removes tool marks and irregularities | 0.4–1.6 | Shafts, gears |

| Polishing | Produces mirror-like smoothness | 0.1–0.4 | Aerospace, medical |

| Shot Peening | Induces compressive stress | 0.8–1.6 | Springs, turbine parts |

| Chemical Polishing | Dissolves surface asperities | 0.2–0.8 | Stainless steel |

| Coating (PVD/Anodizing) | Improves corrosion & wear | N/A | Aluminum, titanium |

Optimizing the process depends on component function, cost constraints, and operating conditions. Forged components may only require minor polishing, while cast parts often need grinding and coating.

Industrial Case Studies

- Automotive: Forged connecting rods with Ra ≤ 0.8 µm demonstrated 20% longer fatigue life than machined cast alternatives.

- Aerospace: Investment-cast turbine blades improved oxidation resistance by 50% after fine polishing and coating.

- Heavy Machinery: Forged hydraulic pistons achieved threefold wear life improvement when shot-peened and polished.

These examples show that surface roughness optimization not only enhances strength and wear resistance but also lowers maintenance costs across industries.

Emerging Trends in Surface Engineering

Future advances in surface metrology and modeling are redefining quality control. Technologies such as:

- AI-based defect detection for predicting surface fatigue.

- Laser texturing to create functional micro-patterns improving lubrication.

- Hybrid manufacturing combines forging, casting, and additive layering for tailored surfaces.

- Sustainability is also becoming central, driving innovations in eco-friendly polishing compounds and low-energy finishing methods to reduce environmental impact.