A vital component of contemporary production, stainless steel is valued for its strength, resilience to corrosion, and longevity. 304 and 316L are two of the most widely utilized austenitic stainless steels among the many grades that are available. While they share many similarities, understanding their differences—particularly in terms of price and performance—is crucial for making informed decisions in casting applications.

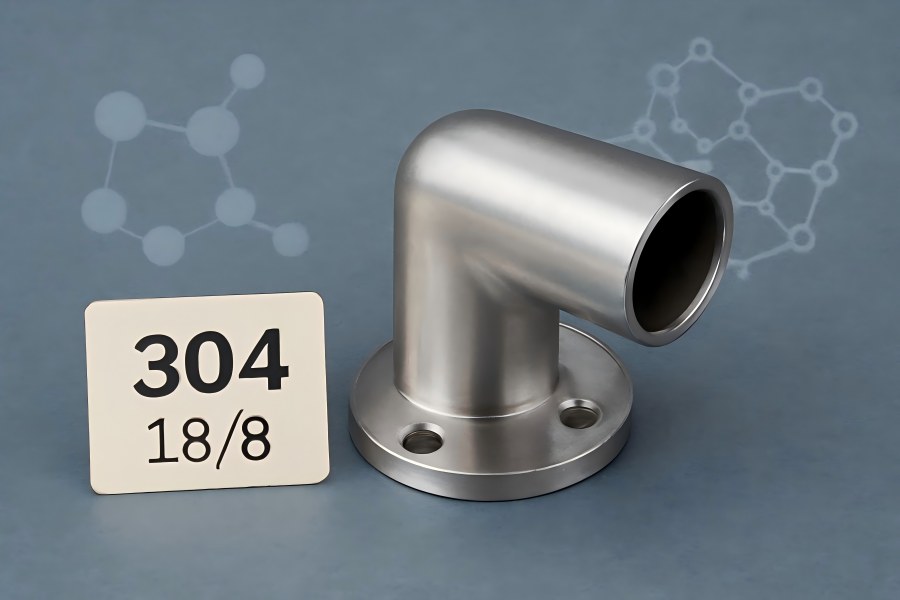

What is 304 Stainless Steel?

The most widely used stainless steel grade is 304, commonly known as “18-8,” due to its composition, which includes around 18% chromium and 8% nickel. This austenitic stainless steel, which belongs to the 300 class, is renowned for its exceptional formability and resistance to corrosion.

Key Characteristics of 304 Stainless Steel

- Corrosion Resistance: 304 stainless steel offers good resistance to oxidation and corrosion in many environments, including atmospheric, chemical, and food-processing environments.

- Formability and Weldability: It is ideal for a variety of applications due to its superior forming and welding properties.

- Strength: It is not as strong as certain other types of stainless steel, despite having a reasonable tensile strength.

- Temperature Resistance: When used intermittently, 304 stainless steel can tolerate temperatures as high as 870°C (1600°F), and when used continuously, it can endure temperatures as high as 925°C (1700°F).

Common Applications of 304 Stainless Steel

304 stainless steel is versatile and finds use in numerous applications, including:

- Kitchen Equipment: Sinks, countertops, and kitchen utensils.

- Food Processing: Equipment and containers that require sanitary conditions.

- Architectural: Building facades, handrails, and structural components.

- Automotive: Exhaust systems and trim.

- Chemical Processing: Tanks and piping systems.

What is 316L Stainless Steel?

316L stainless steel, a low-carbon form of 316, provides enhanced corrosion resistance and better weldability. Because of the molybdenum (2–3%) it contains, it is more resistant to corrosive substances like chlorides.

Key Characteristics of 316L Stainless Steel

- Better Resistance to Corrosion: In chloride conditions, molybdenum’s inclusion improves resistance to pitting and crevice corrosion.

- Weldability: Better weldability results from the reduced carbon content, which lowers the possibility of carbide precipitation during welding.

- Strength: 316L offers higher tensile and yield strength compared to 304, especially at elevated temperatures.

- Resistance to Temperature: Like 304, it can tolerate temperatures of up to 925°C (1700°F) when used continuously and up to 870°C (1600°F) when used intermittently.

Common Applications of 316L Stainless Steel

Due to its enhanced properties, 316L is preferred in more demanding environments:

- Marine Environments: Boat fittings, seawater equipment, and coastal architectural applications.

- Chemical Processing: Equipment exposed to aggressive chemicals.

- Pharmaceutical: Components requiring stringent sanitary conditions.

- Medical Devices: Implants and surgical equipment.

- Food Processing: Equipment that comes into contact with caustic materials.

304 and 316L Stainless Steel’s Main Distinctions

| Property | 304 Stainless Steel | 316L Stainless Steel |

| Corrosion Resistance | Good | Excellent, especially in chloride environments |

| Molybdenum Content | None | 2–3% |

| Weldability | Good | Excellent (low carbon content) |

| Strength | Moderate | Higher, especially at elevated temperatures |

| Cost | Lower | Higher |

| Magnetic Properties | Slightly magnetic | Non-magnetic |

Price Differences

The price of stainless steel grades varies based on factors like raw material costs, alloy composition, and market demand.

Because of its increased resistance to corrosion and the addition of molybdenum, 316L stainless steel has historically been more costly than 304.

- 304 Stainless Steel: Prices typically range from $2.50 to $5.94 per kilogram, depending on market conditions and form (sheet, plate, coil).

- 316L Stainless Steel: Prices are generally higher, ranging from $3.87 to $7.00 per kilogram.

These price differences can influence material selection in casting applications, especially when budget constraints are a factor.

Performance Considerations in Casting

When selecting between 304 and 316L stainless steel for casting applications, several factors should be considered:

- Corrosion Resistance: If the cast component will be exposed to harsh chemicals or marine environments, 316L is the better choice due to its superior resistance to corrosion.

- Mechanical Properties: For applications requiring higher strength, especially at elevated temperatures, 316L offers enhanced tensile and yield strength.

- Weldability: 316L has superior weldability because of its low carbon content, which lowers the possibility of carbide precipitation during the casting process.

- Cost Constraints: While 316L offers superior properties, its higher cost may be prohibitive in applications where these enhanced properties are not necessary.

- Casting Process Compatibility: Sand casting, investment casting, and die casting are just a some of the casting techniques that both grades can be used with. However, the specific requirements of the casting process, such as temperature control and mold materials, should be considered.

Which One Should You Choose?

The decision between 304 and 316L stainless steel for casting applications depends on the specific requirements of the project:

- Choose 304 Stainless Steel: If the application involves environments with low to moderate corrosion risk, and cost considerations are paramount, 304 is a suitable choice.

- Choose 316L Stainless Steel: If the application involves exposure to harsh chemicals, marine environments, or requires higher strength and superior corrosion resistance, 316L is the preferred material.