Estimating the costs for forging custom projects is essential for determining project feasibility, pricing, and profitability. Understanding the key components that make up the forging cost and utilizing the right methods and tools for calculation will help ensure accurate estimates and optimize the manufacturing process.

Understanding Forging Cost Components

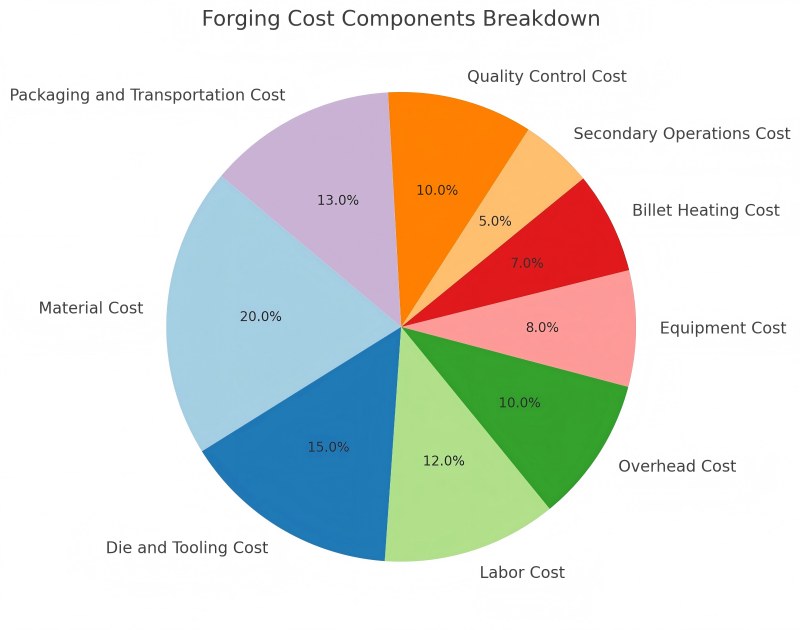

It’s critical to dissect the numerous elements that go into the overall cost in order to get an accurate forging cost estimate:

- Material Cost: The price of the raw materials that go into making forging. The type of material, weight, and unit market price all affect this expense.

- Labor Cost: The wages or hourly rates of the workforce involved in the process. Labor costs are directly related to the amount of time spent on each forging job.

- Tooling Cost: The cost of creating and maintaining the necessary dies, molds, and tools. The quantity of pieces that are anticipated to be produced with the same tooling is used to amortize tooling expenses.

- Overhead Cost: Indirect costs related to operating the business, like utilities, upkeep of equipment, and administrative charges. Usually, overhead is expressed as a proportion of the whole cost of labor or materials.

- Equipment Cost: The depreciation and maintenance cost of the machinery used in the forging process. These are generally spread across the number of pieces produced per year.

- Quality control cost: The price of testing, inspections, and making sure the components are up to par. Costs for testing apparatus, measuring instruments, and quality assurance teams are included in this.

- Packaging and Transportation Cost: These costs include the packaging material and shipping expenses for delivering the final forged parts to the client.

Step-by-Step Forging Cost Estimation

Estimation of forging costs involves calculating each component’s costs and summing them to get the total cost of production. Here’s how to approach it:

Step 1: Material Cost Calculation

The material cost is based on the weight of the forged part and the cost of the material per unit of weight.

Formula:

Material Cost = Gross Weight × Material Price per Unit

Example:

Net weight = 1.5 kg

Material loss = 20% (due to flash and other waste)

Material price = $5/kg

Gross Weight:

Gross Weight=1.5kg×(1+0.20)=1.8kg

Material Cost:

Material Cost=1.8kg×5$/kg=9$

Step 2: Labor Cost Calculation

Labor costs depend on the time spent forging each part. Multiply the time spent on each piece by the labor rate.

Formula:

Labor Cost=Time per Piece×Labor Rate per Hour

Example:

Time per piece = 0.5 hours

Labor rate = $25/hour

Labor Cost:

Labor Cost=0.5hours×25$/hour=12.50$

Step 3: Tooling Cost Calculation

Tooling costs typically involve the creation and maintenance of dies and molds. These costs are divided by the expected number of uses for the tooling.

Formula:

Tooling Cost per Piece=Total Tooling Cost/Expected Number of Uses

Example:

Total die cost = $2,000

Expected uses = 1,000

Tooling Cost:

Tooling Cost=2,000/1,000=2$

Step 4: Overhead Cost Calculation

Overhead costs are typically a percentage of direct labor costs. This can be calculated based on the overhead rate applicable to the operation.

Formula:

Overhead Cost=Labor Cost×Overhead Rate

Example:

Overhead rate = 50%

Overhead Cost:

Overhead Cost=12.50$×50%=6.25$

Step 5: Equipment Cost Calculation

This is the depreciation and maintenance cost of the forging machines.

Formula:

Equipment Cost per Piece=Annual Equipment Cost/Annual Production Volume

Example:

- Annual equipment cost = $10,000

- Annual production volume = 10,000 pieces

Equipment Cost:

Equipment Cost=10,000/10,000 =1$

Step 6: Quality Control Cost Calculation

Quality control costs are usually fixed costs per piece or a percentage of total labor costs.

Formula:

Quality Control Cost=Cost per Piece

Example:

Quality control cost per piece = $1

Step 7: Packaging and Transportation Cost Calculation

Packaging and transportation costs vary depending on the complexity of packaging and delivery.

Formula:

Packaging and Transportation Cost=Cost per Piece

Example:

Packaging and transportation cost per piece = $2

Total Cost per Piece

Now, to get the total cost of each forged part, simply sum all the calculated costs:

Total Cost=9$(material)+12.50$(labor)+2$(tooling)+6.25$(overhead)+1$(equipment)+1$(quality control)+2$(packaging and transportation)=33.75$

Tools and Software for Forging Cost Estimation

There are various software tools designed to assist in the calculation of forging costs, making the process more efficient and accurate:

- FORGE®: A simulation software for hot and cold forming that helps optimize the forging process and estimate costs effectively.

- Costimator®: A comprehensive tool for manufacturing cost estimating, offering support for various processes, including forging.

- Tset: A software tool that automates forging cost estimation based on part geometry and press data.

- FACTON: A cost modeling tool used for die forging, helping to calculate process costs and time based on various parameters.

These tools provide a higher level of accuracy by incorporating real-world data and automating many of the manual calculations.

Practical Tips for Accurate Estimation

- Accurate Data Collection: Ensure that all input data, such as material specifications, labor rates, and machine details, are accurate and up-to-date.

- Account for All Costs: Don’t overlook indirect costs such as overhead and quality control, as they significantly impact total costs.

- Leverage Historical Data: To inform your cost projections and spot areas for cost reduction, use data from earlier projects.

- Update Estimates Frequently: Regularly update estimates to reflect changes in labor costs, material prices, and other variable elements.

- Engage Experts: Work with experienced engineers and cost estimators to refine assumptions and improve accuracy.