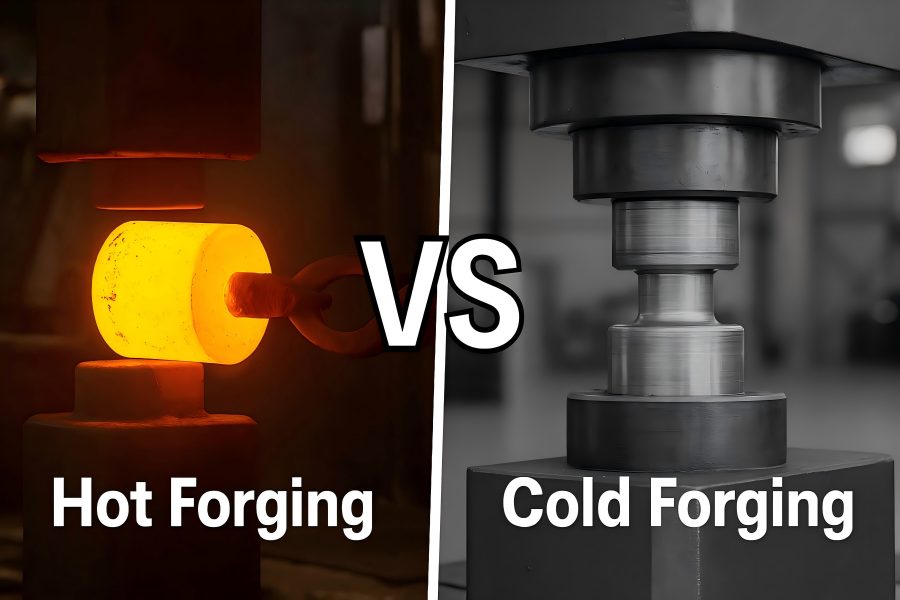

In the world of metal forming, forging remains one of the most trusted processes for producing high-strength, durable, and reliable components. However, not all forging is the same.

The two primary methods—hot forging and cold forging—differ not only in temperature but also in their influence on part quality, production economics, and long-term performance. For industrial buyers, understanding the trade-offs between these two processes is crucial for making informed sourcing decisions.

Understanding Forging Fundamentals

Forging is the process of deforming metal under compressive forces to achieve a desired shape and mechanical structure. By increasing the material’s grain flow, it enhances its strength and resistance to fatigue in comparison to casting or machining. The key distinction between hot and cold forging lies in temperature relative to the material’s recrystallization point.

Heating the metal over its recrystallization temperature—typically between 900 and 1250°C for steel—causes hot forging.

Cold forging takes place near or at room temperature, below the recrystallization point, with no—or minimal—heating involved.

Both methods can produce parts with exceptional structural integrity, but the process parameters determine the outcome in terms of precision, strength, cost, and surface quality.

Hot Forging

In hot forging, metal billets are heated until they become malleable but remain solid. The hot metal is subsequently formed in dies by rolling, pressing, or hammering. Because the material flows easily at elevated temperatures, complex geometries and large parts can be forged without cracking.

Material and Mechanical Advantages

Heating improves ductility, allowing the metal to flow into intricate die cavities. This leads to:

- Excellent formability and reduced risk of work hardening.

- Refined grain structure due to recrystallization, producing uniform strength.

- Enhanced impact resistance and fatigue strength, making hot-forged parts suitable for heavy-duty applications.

For instance, automotive crankshafts, connecting rods, gears, and turbine disks are commonly hot-forged because they must endure high mechanical loads.

Cost and Production Considerations

Although heating the metal requires more energy, hot forging offers economic efficiency for large, complex parts that would otherwise demand excessive machining or die stress in cold conditions. The process also accommodates lower-grade materials that might be too brittle for cold deformation.

However, dimensional tolerances are looser because thermal expansion and cooling shrinkage can cause minor distortion. As a result, hot-forged components often require post-forging machining to achieve precision.

When Hot Forging Excels

Hot forging adds the most value when:

- The component is large, heavy, or highly contoured.

- Mechanical strength and toughness outweigh the need for surface finish.

- Material properties benefit from grain refinement through recrystallization.

- Production runs are medium to large, where heating costs are amortized.

Industries like aerospace, energy, heavy machinery, and automotive drivetrains rely heavily on hot forging because the parts must resist impact, pressure, and cyclic stresses over long lifespans.

Cold Forging

Using high-pressure dies and lubricant to reduce friction, cold forging shapes metal at or close to room temperature. The method is perfect for small to medium-sized components that need strict dimensional control and large production numbers because it doesn’t need heating.

Key Mechanical and Surface Benefits

Cold forging provides several unique advantages:

- Superior surface finish with minimal scaling or oxidation.

- Outstanding dimensional precision, frequently obviating the necessity for machining.

- Work hardening during deformation increases yield and tensile strength.

- Greater material utilization, with near-net-shape forming reducing waste.

These characteristics make cold forging suitable for fasteners, bolts, shafts, bearings, and precision automotive parts, where smooth surfaces and consistent tolerances are essential.

Limitations and Tooling Costs

However, the very strengths of cold forging also impose constraints:

- The process demands softer, ductile materials (e.g., aluminum, copper, mild steel).

- Die wear and press tonnage are significant concerns, especially for harder metals.

- Tooling costs are higher, as dies must withstand extreme pressure and friction.

Additionally, because the metal isn’t recrystallized, internal stresses can accumulate, requiring post-forging heat treatment to restore ductility.

When Cold Forging Adds More Value

Cold forging creates value for buyers when:

- High volumes justify the upfront cost of precision dies.

- The design demands tight tolerances or mirror-smooth surfaces.

- Weight savings and consistency are vital to performance.

- Post-processing costs need to be minimized.

Typical applications include engine bolts, wheel studs, rivets, pinions, and small shafts used in automotive and consumer products. For these parts, the combination of speed, precision, and repeatability makes cold forging highly economical.

Key Technical Comparisons

| Feature | Hot Forging | Cold Forging |

| Temperature | Above recrystallization (e.g., 900–1250°C) | Room temperature or slightly warmed |

| Formability | Excellent (easy metal flow) | Limited (risk of cracking) |

| Strength | Uniform, tough, ductile | Very high (work-hardened) |

| Surface Finish | Rougher; requires machining | Smooth and bright |

| Dimensional Accuracy | Moderate; may distort | Excellent; near-net shape |

| Die Life | Longer (lower stress) | Shorter (high stress) |

| Energy Use | High (heating required) | Lower (no heating) |

| Post-Processing | Often needed | Usually minimal |

| Typical Materials | Alloy steels, titanium, nickel, copper | Aluminum, mild steels, brass |

| Best for | Large, complex, high-stress parts | Small, precise, high-volume parts |

This table highlights the fundamental trade-off: hot forging prioritizes formability and toughness, while cold forging focuses on accuracy and efficiency.

Value Creation for Industrial Buyers

Evaluating Value Beyond Price

Industrial buyers often focus on unit cost, but total value arises from multiple cost drivers—material performance, processing efficiency, lifecycle durability, and post-processing needs. A lower price per part may not equate to higher value if the component fails earlier or requires extensive machining.

The Lifecycle Value Equation

When comparing hot and cold forging, buyers should consider the total cost of ownership (TCO):

TCO=Material Cost+Energy + Tooling+Machining/Finishing+Maintenance + Replacement

Hot forging incurs more upfront energy cost but can extend part life, reducing replacements.

In this framework:

- Hot forging incurs more upfront energy cost but can extend part life, reducing replacements.

- Cold forging lowers per-part production costs at scale, but for hard alloys, tooling wear may increase maintenance costs.

Quality Consistency and Reject Rates

Cold forging provides consistent quality with minimal variation, especially in automated production. Hot forging, however, may show dimensional scatter due to thermal fluctuations and cooling rates. Yet, for high-stress components where metallurgical integrity is paramount, hot forging’s grain flow alignment ensures superior reliability.

Material Efficiency and Waste Reduction

Cold forging can achieve up to 90–95% material utilization, reducing scrap and machining chips. Hot forging typically yields around 80–85%, but it allows the use of cheaper raw material grades that are difficult to form cold.

Lead Time and Flexibility

Cold forging offers faster cycle times once tooling is established, but hot forging provides greater design flexibility—a vital advantage for custom or low-volume parts. Buyers producing varied product lines (e.g., heavy equipment, aerospace prototypes) benefit from hot forging’s adaptability, while automotive OEMs benefit from cold forging’s high repeatability.

Application-Specific Value Analysis

Automotive Components

- Hot Forging Value: Crankshafts, connecting rods, gears, and steering knuckles rely on fatigue resistance and impact toughness. Here, hot forging ensures longer service life.

- Cold Forging Value: Fasteners, wheel bolts, shafts, and brackets demand precision and volume efficiency, where cold forging dominates.

Result: Both coexist—hot for load-bearing, cold for precision.

Aerospace and Energy

Aerospace components must withstand thermal cycling, high stress, and corrosion. Hot forging of titanium and nickel alloys refines grain flow, delivering optimal strength-to-weight ratios. Cold forging’s application is limited to secondary fittings or small connectors due to material hardness constraints.

Result: Hot forging delivers far greater value for performance-critical aerospace components.

Industrial Machinery and Heavy Equipment

Hot forging enables large, complex parts like gear blanks, shafts, couplings, and valve bodies. Cold forging cannot handle these geometries or sizes economically.

Result: For structural or heavy-load parts, hot forging adds the most value.

Electronics, Fasteners, and Consumer Goods

Cold forging produces micro-precision components in large volumes, such as smartphone housings, screws, and electric motor parts. High speed and accuracy lower unit cost dramatically.

Result: Cold forging dominates high-volume, precision-critical production.

Environmental and Sustainability Considerations

Modern industrial buyers are increasingly aware of environmental impact. Energy efficiency and waste reduction are two sustainability goals that forging processes now need to meet.

- Hot forging’s drawback: High energy consumption for heating furnaces and oxidation losses.

- Cold forging’s advantage: Energy-saving, less scaling, and reduced lubricant waste when optimized.

However, many hot forging plants are transitioning to induction heating, heat recovery systems, and closed-loop cooling, narrowing the sustainability gap. Additionally, hot-forged components often last longer, offsetting energy use over their lifecycle.

Hybrid and Warm Forging: A Bridge Between Extremes

To balance the benefits of both methods, manufacturers increasingly employ warm forging—processing at temperatures between 200°C and 700°C. It combines improved formability (from partial heating) with better dimensional control (from reduced thermal distortion).

Warm forging:

- Reduces die stress compared to cold forging.

- Cuts energy consumption relative to hot forging.

- Minimizes scaling, improving surface finish.

For buyers, warm forging may offer a cost-performance compromise, especially in automotive and machinery sectors seeking both strength and precision.

Supplier Selection: What Buyers Should Evaluate

When sourcing forged components, industrial buyers should not only specify the process but also assess supplier capability and certification standards.

Certification and Quality Systems

- ISO 9001 / IATF 16949: Automotive quality management.

- AS9100: Quality of Aerospace Forging.

- ISO 14001: Management of the environment.

- NADCAP: Aerospace-specific process certification.

Equipment and Process Control

Modern CNC forging presses, induction heaters, and die simulation software enhance precision.

Suppliers using Finite Element Analysis (FEA) can predict material flow and optimize die design.

Post-Processing Capabilities

Heat treatment, machining, and non-destructive testing (NDT) capabilities affect final quality and cost.

Surface finishing methods like shot blasting, coating, or grinding determine readiness for assembly.

Supply Chain and Volume Flexibility

Cold forging suppliers often serve high-volume contracts, while hot forging vendors provide custom or low-volume specialty work. Buyers should match supplier strengths to product mix and forecast demand.

Cost Comparison in Real-World Scenarios

| Application | Preferred Process | Reason | Cost Implication |

| Automotive fasteners | Cold forging | Tight tolerances, mass production | Low per-unit cost |

| Turbine shafts | Hot forging | Large size, high load | High energy, low tooling cost |

| Hydraulic fittings | Warm forging | Mid-size, needs accuracy and strength | Balanced cost |

| Aerospace disks | Hot forging | Critical fatigue resistance | High cost, high reliability |

| Electric motor shafts | Cold forging | Smooth surface, repeatable shape | Moderate cost, low waste |

In short, value depends on balancing production economics with performance outcomes. A cheap cold-forged bolt adds less value if it fails early, while a hot-forged gear that lasts twice as long can justify a higher upfront cost.