Duplex Stainless Steel Castings

- Our duplex stainless steel castings combine high strength with exceptional resistance to pitting, crevice attack, and stress corrosion cracking in chlorides.

- They enable lighter, durable pumps, valves, impellers, and housings, reducing maintenance and cost across marine, oil and gas, and chemical processing.

- PREN 24–40+ Resists Pitting and Crevice Attack

- Yield 400–750 MPa with High Toughness

- Thin Walls Castable to 0.5 mm

- Lower Ni 1–8% Cuts Alloy Cost

- Meets EN, BS, AISI, ASTM, JIS Standards

Types of Duplex Stainless Steel Castings

Select the right duplex grade for strength, corrosion resistance, and budget across lean, standard, and super options in chloride environments.

Lean Duplex Stainless Steel Castings

- 20–23% Cr, low Ni and Mo, nitrogen strengthened.

- PREN about 24–30 for moderate chloride resistance.

- Yields roughly 400–550 MPa with good toughness.

- Cost-effective choice for water systems and pulp paper.

Standard Duplex Stainless Steel Castings

- ~22% Cr, 4.5–6.5% Ni, ~3% Mo with nitrogen.

- PREN around 32–38 for strong pitting resistance.

- Yield about 450–620 MPa, twice 304 or 316.

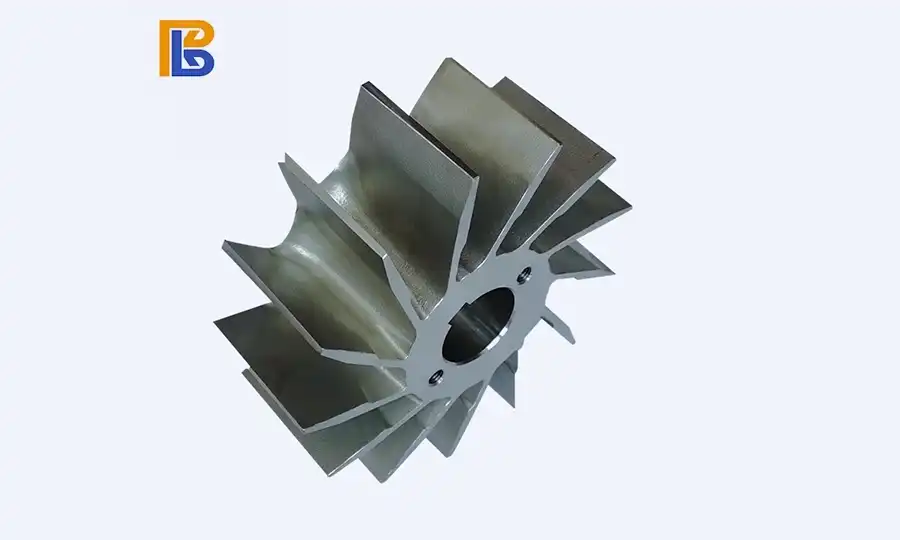

- Common in pumps, valves, impellers, and pressure housings.

Super Duplex Stainless Steel Castings

- 24–26% Cr, 6–8% Ni, 3–4% Mo, nitrogen alloyed.

- PREN ≥40 for seawater chloride SCC resistance.

- Yield 550–750 MPa, high toughness after annealing.

- Suited to offshore, subsea, desalination, and chemical processing.

Typical Grades and Chemistry (wt%)

Reference duplex grades and nominal chemistries to align your cast specifications with UNS ranges and corrosion performance targets.

TYPE | C≤ | Mn≤ | Si≤ | S≤ | P≤ | Cr | Ni | Mo | Cu≤ | N |

S32750 (SAF2507) OOCr22Ni7Mo4N | 0.03 | 1.2 | 0.8 | 0.02 | 0.035 | 24.0/26.0 | 6.0/8.0 | 3.0/5.0 | 0.5 | 0.24/0.32 |

S31803 (SAF2205) OOCr22Ni5Mo3N | 0.03 | 2 | 1 | 0.02 | 0.03 | 21.0/23.0 | 4.50/6.50 | 2.50/3.50 | — | 0.08/0.20 |

S31500(3RE60) OOCr18Ni5Mo3Si2 | 0.03 | 1.2/2.00 | 1.4/2.00 | 0.03 | 0.03 | 18.0/19.0 | 4.25/5.25 | 2.50/2.00 | — | 0.05/0.10 |

Key Advantages

Corrosion Resistance

Duplex stainless resists pitting, crevice attack, and chloride cracking; supplied to EN, BS, AISI, ASTM, JIS (ASTM A351, A995).

High Strength with Toughness

Higher mechanical properties with better ductility and toughness, without brittleness at room temperature.

Cost Efficient and Weldable

Nickel saving stainless design with excellent welding performance reduces material cost and eases fabrication.

Precision Castability and Design Flexibility

Thin walls to 0.5 mm, surface roughness Ra 1.6–3.2, machining to ±0.009 mm, weights 1 g–99 kg (sand casting 0.5–500 kg).

Tailored Solutions with Timely Delivery

We deliver custom duplex stainless steel castings on time, from small batches to large runs. Please contact us!

Our Duplex Stainless Steel Castings

Duplex Stainless Steel Angle Valve Body

Super Duplex Stainless Steel Open Impeller

Super Duplex Stainless Steel Equal Tee Fitting

Applications

Our duplex stainless steel castings perform in chloride-rich, high-load environments across multiple industries. Below are typical use cases and parts we supply.

Marine and Seawater Systems

Resists seawater pitting and crevice corrosion, enabling pump casings, valve bodies, impellers, propeller hubs, thruster housings, intake screens, and desalination components.

Petroleum Refining

Handles chlorides and high temperatures in refineries, serving pump casings, manifolds, valve trims, exchanger covers, reactor hardware, flanges, connectors, and headers.

Chemical Fertilizer Production

Corrosion resistant for ammonia and urea plants, covering stripper parts, condenser components, pumps, valves, carbamate lines, washdown hardware, and critical piping.

Pulp and Paper (Papermaking)

Withstands bleach liquors and abrasive fiber slurries, supplying liquor pumps, agitators, refiners, washers, bleach-plant hardware, piping components, brackets, and supports.

Chemical Industry

Reliable in mixed acids, chlorides, and caustics, delivering reactor components, mixers, filter housings, instrumentation bodies, pipe fittings, fasteners, and structural parts.

Heat Exchangers

Superior resistance to chloride cracking and erosion, suitable for shells, channel heads, tube sheets, baffles, covers, seawater-cooled condensers, and coolers.

Cold Showers / Cooling-water Showers

Corrosion and erosion resistant for cold-water washdown and cooling, producing spray nozzles, headers, distribution manifolds, structural brackets, distribution bars, and supports.

Contact Us Now

FAQs

1. Which casting processes do you use?

We manufacture duplex stainless steel castings via investment casting for precision, sand for components, and shell molding when repeatability and surface finish are critical.

2. What sizes and weights can you cast?

Size capabilities for duplex stainless steel castings span sub-0.5-kilogram parts to multi-hundred-kilogram housings, depending on process route, tooling, geometry, and tolerances.

3. What surface finishes are available?

Surface finishes for duplex stainless steel castings vary by process. Offer shot blasting, pickling, passivation, machining, and polishing to achieve roughness and appearance targets.

4. Do you perform corrosion testing?

We validate Duplex Stainless Steel Castings’ corrosion performance using ASTM G48 pitting tests, microstructure examinations, and ferrite measurements, confirming solution annealing effectiveness.

5. How do you minimize porosity?

To reduce porosity in duplex stainless steel castings, we optimize gating, risers, chills, and simulation. NDT verifies soundness; critical components may receive HIP.

6. What industries use your duplex castings?

Marine, desalination, oil and gas, chemical, pulp and paper, mining, and power sectors use duplex for strength, corrosion resistance, and lifecycle cost reductions.

7.How do you guarantee traceability and quality?

We apply an ITP with chemistry control, process monitoring, NDT, mechanical testing, inspection, and material certification traceable to heat, lot, tooling, and drawings.

8. Can you meet project-specific standards?

Yes. We align procedures and acceptance criteria to ASTM, ASME, EN, NORSOK, and customer specifications, documenting compliance through inspections, test reports, and certifications.