Custom Aluminum Castings

- We engineer aluminum castings that are lightweight, corrosion-resistant, and precision-finished, with excellent castability and machinability for thin walls and complex geometries.

- Our parts deliver high strength-to-weight and strong thermal performance, reducing mass for automotive, aerospace, energy, and industrial machinery.

- Tight Tolerances ±0.10–0.25 mm

- As-cast Finish Ra 3–6 µm

- Broad Alloy Options to Tune Properties

- Complex Shapes with Cast-in Inserts, Threads, Bosses

- Near-net Shapes That Minimize Machining

What Alloys are Used in Aluminum Castings?

We cast ADC6, ADC12, plus ADC1, ADC3, ADC5, ADC10, ADC10Z, ADC12Z, ADC14. Lightweight, conductive, machinable alloys chosen for strength, corrosion resistance, and castability.

Alloy | Standard | Preferred Process | Key Advantages | Typical Applications |

ADC12 | JIS H 5302; Al-Si-Cu (≈ A383) | HPDC | Excellent fluidity for thin walls; stable as-cast strength | Motor housings, gearbox covers, appliances. |

ADC10 | JIS H 5302; Al-Si-Cu (≈ A380) | HPDC | Balanced strength/castability; good pressure-tightness | Engine brackets, transmission/drive housings. |

ADC10Z | JIS H 5302; ADC10 variant (higher Zn limit) | HPDC | Chemistry aligned to foreign specs; properties similar to ADC10, but slightly worse corrosion & crack resistance | Sealing/cover parts where standardization matters. |

ADC12Z | JIS H 5302; ADC12 variant (higher Zn limit) | HPDC | Chemistry aligned to foreign specs; similar to ADC12 | Pump bodies, pressure covers. |

ADC6 | JIS H 5302; Al-Mg-Mn (not A360-type) | HPDC | Very good corrosion resistance, castability slightly better than ADC5, less fluid than Al-Si alloys | Outdoor/marine fittings, transport hardware. |

ADC5 | JIS H 5302; Al-Mg | HPDC | High elongation/impact; best corrosion resistance among JIS Al-Mg die-cast grades; lower castability | Brackets and hardware needing ductility & corrosion resistance. |

ADC3 | JIS H 5302; Al-Si-Mg (≈ A360) | HPDC | Better corrosion & elevated-temp strength than ADC10/12; harder to cast than ADC12 | Transmission cases, higher-temp housings. |

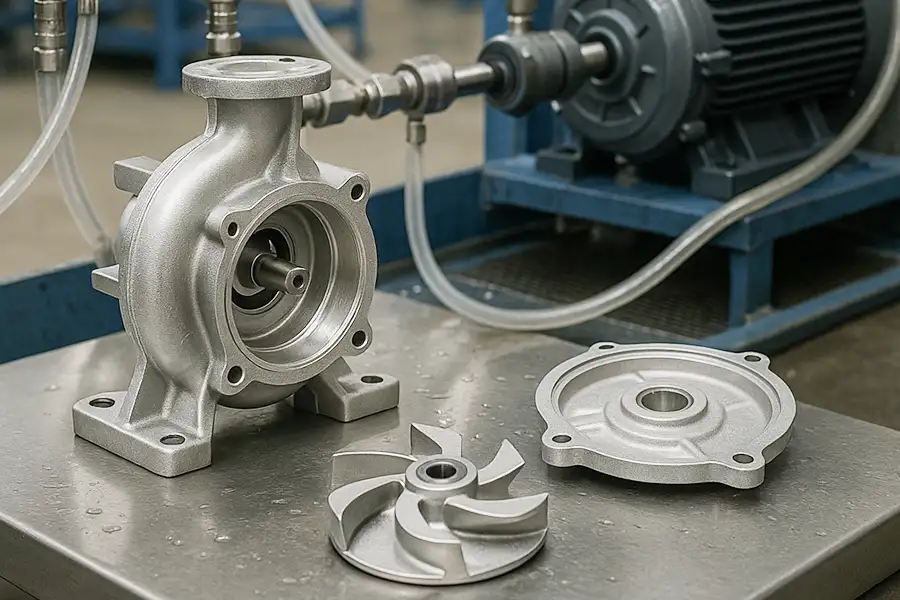

ADC1 | JIS H 5302; Al-Si12-type (≈ A413) | HPDC | Excellent die filling and pressure-tightness; good for intricate shapes | Pump/hydraulic bodies, thin-wall housings. |

ADC14 | JIS H 5302; High-Si specialty (≈ B390) | HPDC (optimized tooling) | Outstanding wear & thermal stability; low shrinkage | Pistons, cylinder bores/liners, compressor scrolls, high-wear housings. |

A356 | ASTM B26/B108; Al-Si-Mg (heat-treatable) | Sand / PM / LPDC (often T6); not suited to HPDC | High strength-to-weight, good ductility & corrosion resistance | Wheels, suspension, pump/valve bodies. |

Post-processing Services for Aluminum Castings

From heat treatment to finishing, we deliver end-to-end post-processing to meet tight tolerances, sealing, appearance, and performance.

Heat Treatment

Tailored solution and aging heat treatment improve aluminum castings' strength, hardness, and dimensional stability while relieving stress and minimizing distortion.

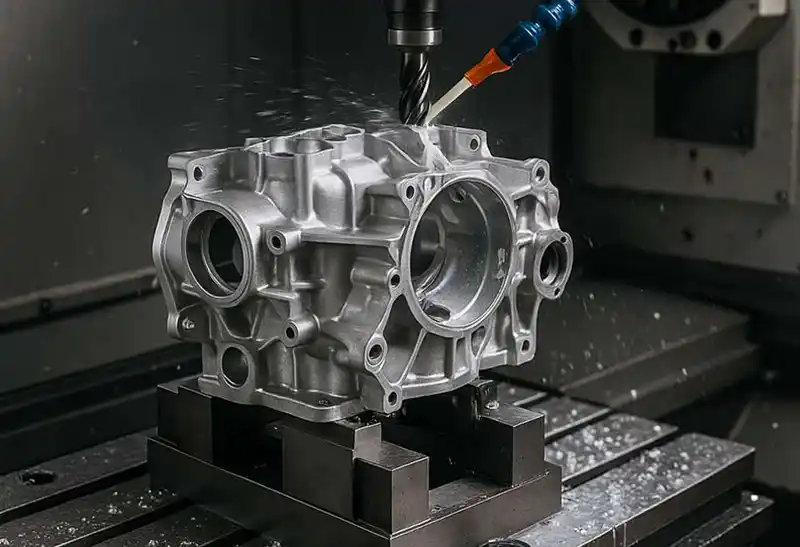

Machining

Precision CNC machining achieves tight tolerances on aluminum castings, drilling, tapping, milling, and turning, ensuring assembly-ready surfaces.

Welding

Specialized aluminum welding repairs porosity, cracks, misruns, joining cast sections securely preserving properties and minimizing heat-affected distortion.

Anodizing

Anodizing builds a durable oxide layer on aluminum castings, enhancing corrosion resistance, wear protection, dye coloring, and surface adhesion.

Powder Coating

Powder coating delivers chip-resistant finishes on aluminum castings, improving weatherability, consistency, and protection without solvent emissions.

Painting

Industrial painting provides primers and topcoats for aluminum castings, enhancing corrosion resistance, UV stability, brand color, and appearance.

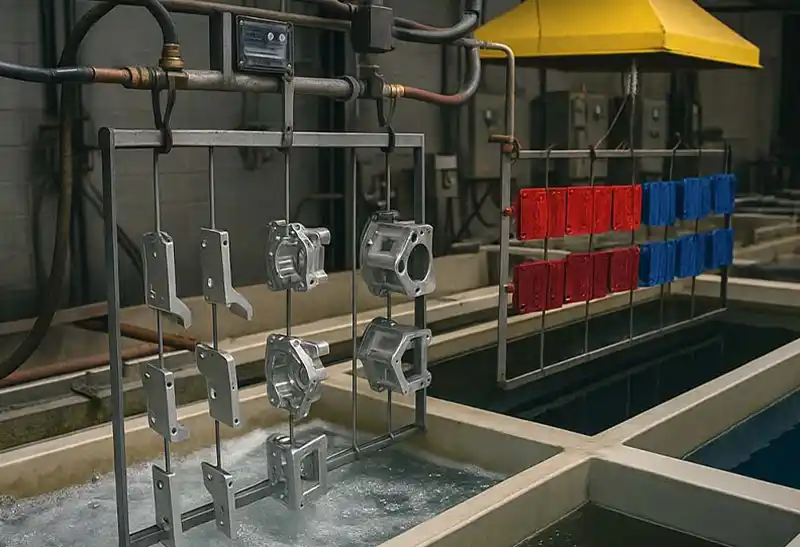

Electroplating

Electroplating aluminum castings uses zincate pretreatment for adhesion, nickel or chrome layers that enhance conductivity, wear resistance & appearance.

Shot Blasting

Shot blasting cleans aluminum castings, removing sand, scale, and flash, creating textures that improve coating adhesion and reveal surface defects.

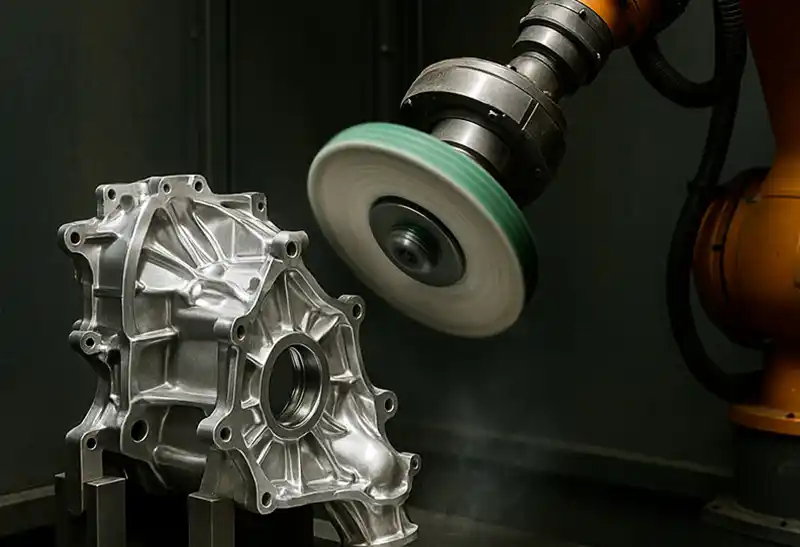

Polishing

Polishing refines aluminum casting surfaces to low roughness, reducing friction and improving aesthetics before anodizing, painting, or sealing.

Tolerance for Aluminum Castings

The table outlines our typical ranges. We determine final tolerances after reviewing the alloy, casting process, part geometry, tooling accuracy, and the inspection standards specified on your drawing.

Parameter | Range |

Dimensional Tolerance | ±0.005 to ±0.010 inches |

Wall Thickness Tolerance | ±0.010 to ±0.020 inches |

Surface Finish (Ra) | 3.175–6.35 µm |

Roundness | ±0.002 to ±0.005 inches |

Flatness | 0.005 to 0.010 inches |

Straightness | 0.005 to 0.015 inches |

Angular Tolerance | ±0.5° to ±1° |

Cavity Dimensions | ±0.010 to ±0.020 inches |

Weight Tolerance | ±1% to ±3% |

Core Shift | ±0.005 to ±0.010 inches |

Porosity | ≤ 1% |

Casting Shrinkage | 1.5% to 3% |

Material Density | 2.60 to 2.75 g/cm³ |

Hardness | 50 to 90 HRB |

Tolerance on Threaded Holes | ±0.005 to ±0.015 inches |

Position Tolerance | ±0.010 to ±0.030 inches |

Thickness-to-Diameter Ratio | 1:1 to 1:3 |

Impact Resistance | 5 to 15 J |

Tensile Strength | 100% |

Elongation | 5% to 10% |

Tailored Solutions with Timely Delivery

We deliver custom-cast aluminum casting parts on time, from small batches to large runs. Please contact us!

Our Aluminum Casting Parts

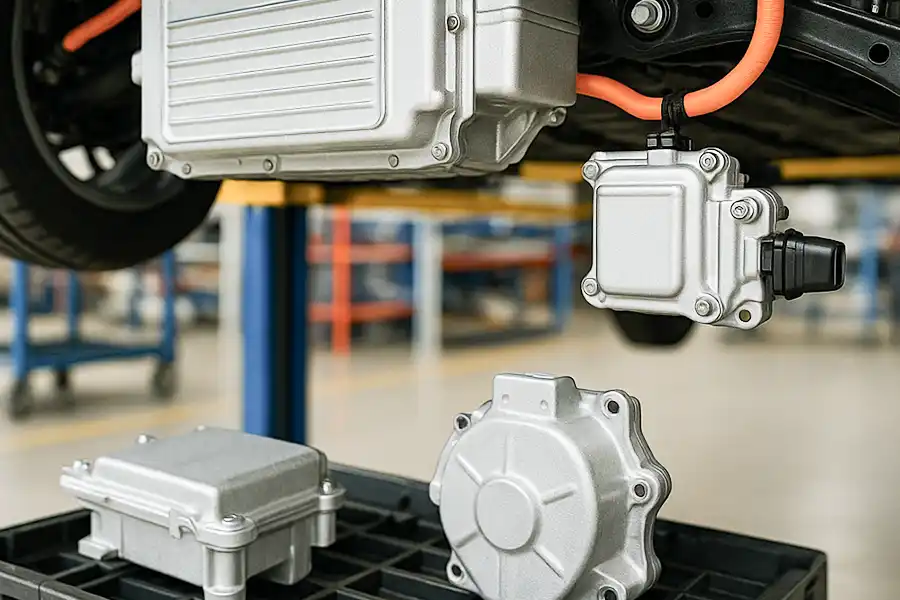

Aluminum Motor End Cover Castings

- Lightweight, high-strength, corrosion-resistant.

- Easier to modularize and ideal for welding.

- Extensively utilized in the automotive industry.

- Popular in aviation, power, and transport machinery.

Die Casting Mechanical Housing

- Regular materials include ADC6, ADC12.

- Good machinability and surface finish.

- Suitable for welding, excellent for conducting heat.

- Machined surfaces follow GB/T 6060.4.

Aluminium Spare Parts

- Lighter than stainless and other steels.

- Thin walls are achievable, stable dimensions.

- Supports modular assembly and integration.

- Complex shapes with high precision.

Applications

Our aluminum castings combine low weight, excellent heat dissipation, good machinability, and high dimensional accuracy. They suit thin-wall, complex components across many sectors.

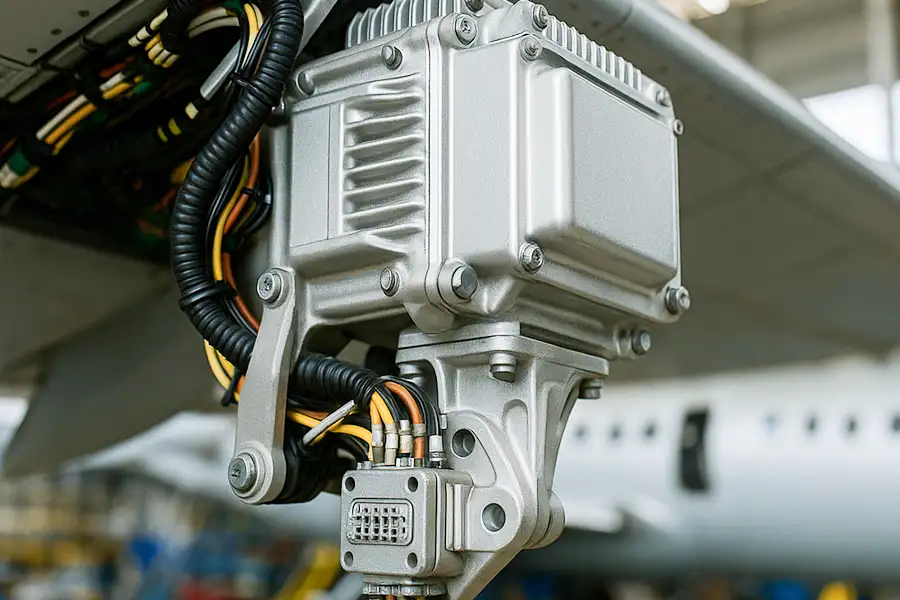

Aerospace and Defense

Lightweight brackets, actuator housings, avionics enclosures, and pump bodies provide strength, thermal management, corrosion resistance, and reliability.

Automotive and Motorcycle

EV battery cases, ECU enclosures, gearbox covers, and chassis brackets reduce mass, enhance cooling, and resist vibration.

Internal Combustion Powertrain

Engine blocks, cylinder heads, and intake manifolds provide complex passages, precise geometry, strong conductivity, and stable dimensions.

Electric Motors and Drives

End covers, stator housings, and fans ensure accurate fits, efficient heat transfer, reduced noise, and longevity.

Oil and Fluid Pumps

Pump bodies, impellers, volutes, and valve housings maintain pressure, resist corrosion, integrate passages, and reduce leakage.

Power and Electrical Infrastructure

Transformer housings, switchgear parts, and heat sinks provide conductivity, weather resistance, outdoor durability, and long life.

Industrial Transmission and Machinery

Gearbox housings and machine covers deliver stiffness, reduced weight, stable dimensions, faster assembly, and easier maintenance.

Architecture and Landscaping

Facade fittings, curtain-wall components, lighting housings, and bollards provide surfaces, weather resistance, pleasing appearance, and sustainable finishes.

Precision Instruments and Medical Devices

Frames and device housings provide tight tolerances, stable dimensions, clean surfaces, and reliable sterilization compatibility.

Contact Us Now

FAQs

1.Which casting processes do you offer?

We provide high-pressure die casting, low-pressure die casting, gravity permanent mold casting, and sand casting. Process selection depends on geometry, volume, mechanical properties, and cost targets requirements.

2.Which aluminum alloys do you commonly use?

Common alloys include ADC12, ADC10, ADC6, A356, and other JIS aluminum grades. We choose chemistry based on strength, corrosion resistance, fluidity, pressure tightness, and machinability needs.

3.What heat treatments can you provide?

We provide T5, T6, and T7 heat treatments for alloys, along with stress relief, aging, and solutionizing, depending on material, geometry, mechanical properties, and dimensional stability.

4.How do you ensure dimensional accuracy?

Dimensional accuracy is ensured through tooling design, thermal control, maintenance, in-process measurements, SPC on critical features, CMM inspection, and PPAP documentation for automotive or regulated requirements.

5.How do you approach tooling design?

Tooling is designed with DFM principles, thermal balance, venting, runner and gate optimization, ejector layout, steel selection, maintenance plans to achieve consistent fills, cycles, and durability.

6.Do you offer assembly and finishing services?

Yes, we can assemble inserts, seals, and hardware, perform surface finishing like anodizing or powder coating, apply sealants, and package to customer standards with barcode labels.

7.What are your minimum order quantities?

We support small prototype batches with no fixed MOQ. Economical production starts around hundred pieces, depending on part size, complexity, finishing, and packing or logistics considerations.

8.What certifications and standards do you meet?

We operate ISO 9001 quality systems, support IATF 16949 requirements when requested, and follow JIS, ASTM, GB, and customer specifications for materials, inspection, packaging, and traceability.