Alloy Steel Castings Manufacturer

- Our alloy steel castings, alloyed with 1.0% to 50% elements, offer exceptional strength, toughness, and corrosion resistance.

- Ideal for industries like energy, oil & gas, and mining, they provide near-net geometric freedom and tailored mechanical properties for complex shapes and demanding applications.

- Yield Strength Above 900 MPa for Durability

- Hardness Between 30-60 HRC for Wear Resistance

- Available in Various Sizes and Weights

- Compliant with EN, BS, AISI, ASTM, and JIS Standards

Based on Alloy Content

We produce low- and high-alloy castings via investment, sand, and shell molding, with heat treatment, machining, and NDT ensuring repeatable quality from prototype to production.

Low Alloy Steel Castings

- <8% alloying elements; balanced strength, toughness, weldability.

- Heat-treatable grades 4130, 4140, 8630 for tailored performance.

- Good castability and machinability; supports complex geometries.

- Used for gears, valve bodies, pumps, mining equipment, and machinery.

High Alloy Steel Castings

- ≥8% alloying; superior corrosion, wear, and heat resistance.

- Includes stainless, duplex, tool, and heat-resistant steel families.

- Stable microstructure and strong oxidation resistance after proper heat treatment.

- Ideal for chemical, power, marine, pulp, food, and oil & gas applications.

Materials & Chemical Composition

Our alloy steel castings are made with precise chemical compositions for optimal performance in various demanding applications.

TYPE | Chemical Composition(%) | ||||||||

| C | Si | Mn | S | P | Cr | Ni | Mo | Cu |

ZG40Mn | 0.30–0.45 | 0.30–0.45 | 1.20–1.50 | ≤0.030

|

|

|

|

| |

ZG40Mn2 | 0.35–0.45 | 0.20–0.40 | 1.60–1.80 | ≤0.030 |

|

|

|

| |

ZG50Mn2 | 0.45–0.55 | 0.20–0.40 | 1.50–1.80 | ≤0.030 |

|

|

|

| |

ZG20SiMn | ≤0.023 | ≤0.60 | 1.00–1.50 | ≤0.025 | ≤0.30 | ≤0.40 | ≤0.15 |

| |

ZG35SiMn | 0.30–0.40 | 0.60–0.80 | 1.10–1.40 | ≤0.030 |

|

|

|

| |

ZG35SiMnMo | 0.32–0.40 | 1.10–1.40 | 1.10–1.40 | ≤0.030 | ≤0.30 | ≤0.30 | 0.20–0.30 | ≤0.30 | |

ZG35CrMnSi | 0.30–0.40 | 0.50–0.75 | 0.90–1.20 | ≤0.030 | 0.50–0.80 |

|

|

| |

ZG20MnMo | 0.17–0.23 | 0.20–0.40 | 1.10–1.40 | ≤0.030 | ≤0.30 | ≤0.30 | 0.20–0.35 | ≤0.30 | |

ZG55CrMnMo | 0.50–0.60 | 0.25–0.60 | 1.20–1.60 | ≤0.030 | 0.60–0.90 | ≤0.30 | 0.20–0.30 | ≤0.30 | |

4130 | 0.28-0.33 | 0.15-0.35 | 0.40-0.60 | ≤0.040 | 0.80-1.10 |

| 0.15-0.25 |

| |

4140 | 0.38-0.43 | 0.15-0.35 | 0.75-1.00 | ≤0.040 | 0.80-1.10 |

| 0.15-0.25 |

| |

4340 | 0.38-0.43 | 0.15-0.35 | 0.60-0.80 | ≤0.040 | 0.70-0.90 | 1.65-2.00 | 0.20-0.30 |

| |

8620 | 0.18-0.23 | 0.15-0.35 | 0.70-0.90 | ≤0.040 | 0.40-0.60 | 0.40-0.70 | 0.15-0.25 |

| |

8627 | 0.25-0.30 | 0.15-0.35 | 0.70-0.90 | ≤0.040 | 0.40-0.60 | 0.40-0.70 | 0.15-0.25 |

| |

8630 | 0.28-0.33 | 0.15-0.35 | 0.70-0.90 | ≤0.040 | 0.40-0.60 | 0.40-0.70 | 0.15-0.25 | ||

Advantages of Alloy Steel Castings

Versatile Size and Weight Range

Alloy steel castings range from small, precision components to large parts exceeding 500 kilograms for diverse industries.

Superior Mechanical Performance

Alloy steel castings offer high strength, toughness, and wear resistance, even in harsh operating conditions.

Design Flexibility

Casting processes allow intricate geometries and internal passages, reducing secondary machining and assembly needs.

Material Customization

Alloying and heat treatment enable tailoring properties like corrosion resistance, hardness, and machinability for specific applications.

Tailored Solutions with Timely Delivery

We deliver custom-cast alloy steel parts on time, from small batches to large runs. Please contact us!

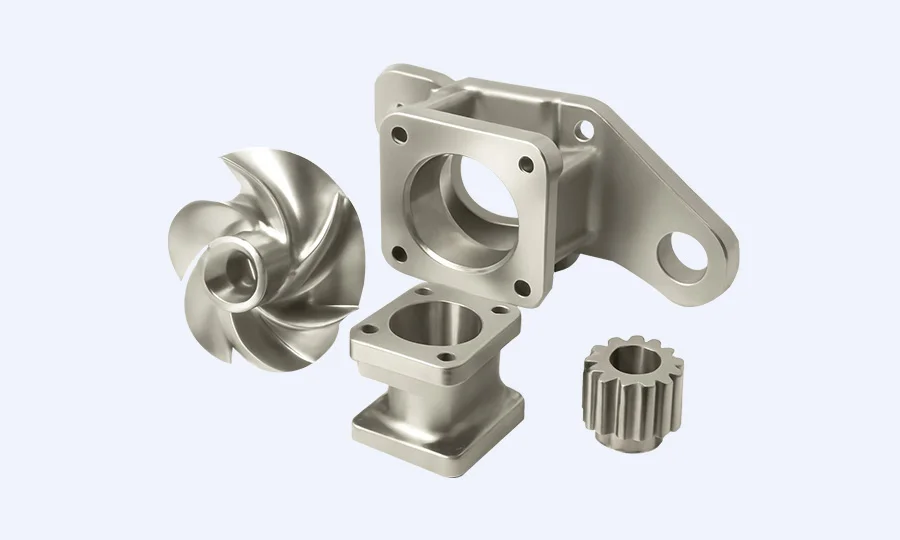

Our Alloy Steel Casting Parts

Alloy Steel Cast Spare Parts

- Dimensions depend on part shape and weight.

- Steel parts 0.001 to 99 kilograms.

- Sand castings 0.5 to 500 kilograms.

- Based on EN BS AISI ASTM JIS standards.

Alloy Steel Impeller Castings

- Enclosed impeller design for maximum containment.

- Semi-open front impeller improves flow efficiency.

- Semi-open back impeller eases solids handling.

- Widely used in hardware manufacturing sectors.

Alloy Steel Lost Wax Castings

- Excellent precision with smooth surface finish.

- Produces complex geometries in alloy steel.

- Fine detail capture reduces post-machining needs.

- Used in construction machinery and heavy equipment.

Typical Applications

Alloy steel castings deliver high strength and wear/heat/corrosion resistance for demanding service across construction, automotive, agriculture, mining, metallurgy, power generation, marine, food, wind-energy, and fluid industries.

Powertrain & Drivetrain

- Gears, pinions, hubs

- Differential carriers and cases

- Input/output shafts and couplers

Flow Control & Fluid Handling

- Valve bodies, bonnets, seats

- Pump casings, impellers, wear rings

- Mixers, agitators, and flow meters

Heavy Equipment & Mining

- Wear components and liners

- Track links, shoes, and sprocket hubs

- Housings, brackets, and frames

Energy & Process Industries

- Burner nozzles and heat-resistant grates

- Furnace fixtures and support hardware

- Chemical/petrochemical pump and valve parts

Marine, Oil & Gas

- Corrosion-resistant housings and couplers

- Subsea brackets, clamps, and connector hardware

- Winch, mooring, and deck equipment components

Electric Power & Wind Energy

- Turbine, generator, and gearbox castings

- Brake components, yaw/pitch hubs, adapters

- Substation and transmission hardware

Metallurgy & Steelmaking

- Furnace/boiler grates and fixtures

- Roller housings and bearing supports

- Ladle and handling hardware

Automotive & Commercial Vehicles

- Suspension/steering brackets and knuckles

- Powertrain mounts and carrier housings

- Driveline flanges and yokes

Agriculture & Garden Machinery

- Gearbox housings, hubs, and flanges

- Tiller, mower, and harvester brackets

- Pump/valve parts for irrigation systems

Contact Us Now

FAQs

1.What materials are used in alloy steel casting?

Alloy steel castings are made from steel alloys that include elements such as chromium, nickel, molybdenum, and vanadium, which improve strength, hardness, and resistance to corrosion.

2.What casting methods are used for alloy steel?

Common casting methods for alloy steel include sand casting, investment casting, shell molding, and die casting, each selected based on the required complexity and material properties.

3.What is the difference between sand casting and shell molding in alloy steel?

Sand casting is cost-effective for larger, simpler parts, while shell molding offers higher precision and better surface finishes, making it ideal for smaller, more complex alloy steel castings.

4.What are the common defects in alloy steel castings?

Common defects include porosity, cracks, misruns, shrinkage cavities, and inclusions. Proper mold design, temperature control, and quality control techniques help minimize these defects during production.

5.What types of tests are conducted on alloy steel castings?

Alloy steel castings undergo various tests, including tensile strength, hardness, impact resistance, X-ray inspections, and ultrasonic testing to ensure the castings meet required mechanical properties and quality standards.

6.Can alloy steel castings be recycled?

Yes, alloy steel castings are fully recyclable, which makes them a sustainable option in manufacturing. Scrap alloy steel can be melted down and recycled without a substantial reduction in its properties.

7.What are the applications of high chrome steel castings in mining?

High chrome steel castings are widely used in mining for equipment like crusher liners and grinding mills, providing superior wear resistance in abrasive environments to increase efficiency and productivity.

8.How do high manganese steel castings perform in wear-resistant applications?

High manganese steel castings provide excellent wear resistance, particularly in applications like mining and quarrying, where heavy abrasion and impact are common, ensuring longer component life.