Stainless Steel Castings Manufacturer

- Our stainless steel castings are produced using advanced investment casting technology, ensuring exceptional precision, strength, and long-lasting durability.

- Available in a range of SS grades, they offer excellent dimensional accuracy, strength, and corrosion resistance, making them ideal for industrial applications.

- Custom Casting Weights: 1g to 500kg

- Dimensional Tolerance: ±0.05mm

- Precision Machining: Surface Roughness Ra0.8-1.6

- Flexible Manufacturing for Complex Shapes

- Compliance with EN, BS, ASTM, and JIS Standards

Common Stainless Steel Castings Types

We manufacture castings using diverse stainless steel alloys, including austenitic, martensitic, ferritic, duplex, and PH types, each engineered for strength, corrosion resistance, and durability.

Duplex Stainless Steel Castings

- Grades: CD4MCu, CE8MN, ZG0Cr25Ni6Mo2Cu2, ZG00Cr22Ni5Mo3N

- Austenite-ferrite structure provides strength and corrosion resistance.

- Resists pitting, stress corrosion in seawater and chemical systems.

- Used in offshore, petrochemical, and desalination system applications.

Austenitic Stainless Steel Castings

- Grades: CF8 (304), CF3M (316L), CF8M (316), CF3 (304L)

- Non-magnetic, corrosion-resistant, tough at varied temperatures.

- Ideal for food, marine, medical, and chemical environments.

- Easily cast, welded, and polished; very structurally versatile.

Martensitic Stainless Steel Castings

- Grades: CA15 (410), CA6NM (13-4), ZGCr17Ni2, ZGCr13

- Strong and wear-resistant for structural, load-bearing parts.

- Moderate corrosion resistance in water, steam, and acid.

- Used in pumps, turbines, and mechanical applications.

Ferritic Stainless Steel Castings

- Grades: ZGCr17, ZGCr28, CB30, ZG00Cr18

- Excellent oxidation resistance at high operating temperatures.

- Suitable for exhausts, furnaces, and thermal structural components.

- Toughness improved by nickel, rare earth elements.

Precipitation-hardening Stainless Steel Castings

- Grades: 17-4PH, 15-5PH, ZG0Cr17Ni4Cu4Nb, 13-8PH

- Heat treatment improves strength and corrosion resistance.

- Used in aerospace, nuclear & precision industrial equipment.

- Excellent weldability and machinability for complex castings.

What Customization Options Do Our Castings Offer?

- Casting Methods: Investment casting (Silica sol and water glass casting).

- Material Grades: Available in a wide range of grades, including austenitic, martensitic, duplex, ferritic, and PH.

- Weight and Dimensions: From a few grams to 500 kg, with maximum dimensions of 1500 x 1500 x 1500 mm.

- Surface Finishing: Shot blasting, pickling, polishing, passivation, and machining.

- Tolerance Control: Tolerances range from ±0.05 mm to ±0.2 mm, depending on the casting method.

- Customization Services: OEM & ODM support, from prototyping to final delivery.

Our Stainless Steel Casting Parts

Stainless Steel Cast Pump

- Corrosion-resistant, shock-absorbing, and customizable production.

- Extensive use in the food and chemical sectors.

- 304L supports welding and high heat resistance.

- 316L is ideal for piping, food-grade applications.

Stainless Steel Cast Valve Housings

- Maximum dimensions up to 1500*1500*1500mm.

- Minimum product thickness as low as 0.5mm.

- Dimension tolerance within CT5-CT6 for accuracy.

- Customized casting surface roughness Ra1.6 to 3.2.

Precision Stainless Steel Castings

- Precision castings range from 1g to 99kg.

- Sand casting starts at 0.5kg for flexibility.

- Finished machining tolerance can reach ±0.009mm.

- Machining surface roughness from Ra0.8 to 1.6.

Applications

Our stainless steel castings deliver strength, precision, and corrosion resistance for demanding industries, supporting applications in turbines, pumps, valves, automotive, aerospace, and industrial equipment.

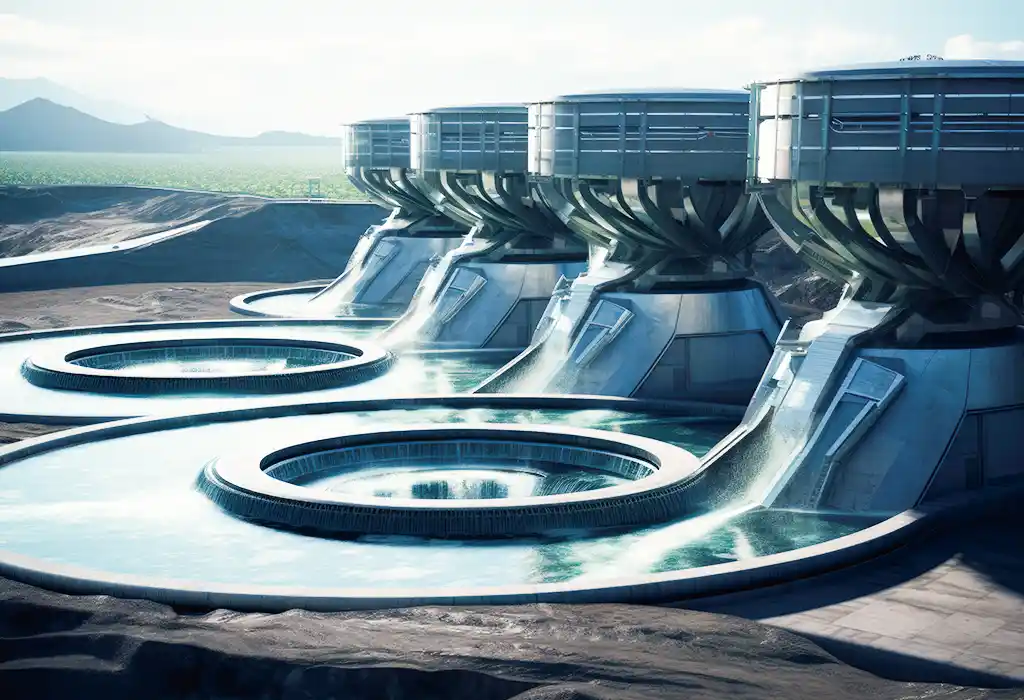

Hydro Power

Stainless steel castings are essential in hydropower plants where components face constant exposure to water, erosion, and pressure fluctuations.

- Typical parts include:

- Turbine runners and blades

- Water guide vanes

- Inlet valve bodies

- Draft tube cones

- Wear rings and sealing seats

Locomotive

Railway systems demand parts with high mechanical strength and resistance to outdoor corrosion, vibration, and mechanical wear.

- Typical parts include:

- Brake discs and pads

- Suspension and traction brackets

- Bogie frame components

- Coupling housings

- Exhaust outlet components

Pumps and Valves

Stainless steel castings are widely used in pump and valve systems that handle aggressive fluids, chemicals, and high pressures.

- Typical parts include:

- Pump casings and impellers

- Valve bodies and bonnets

- Valve discs, seats, and plugs

- Shaft sleeves and sealing components

- Flanged ends and pipe connectors

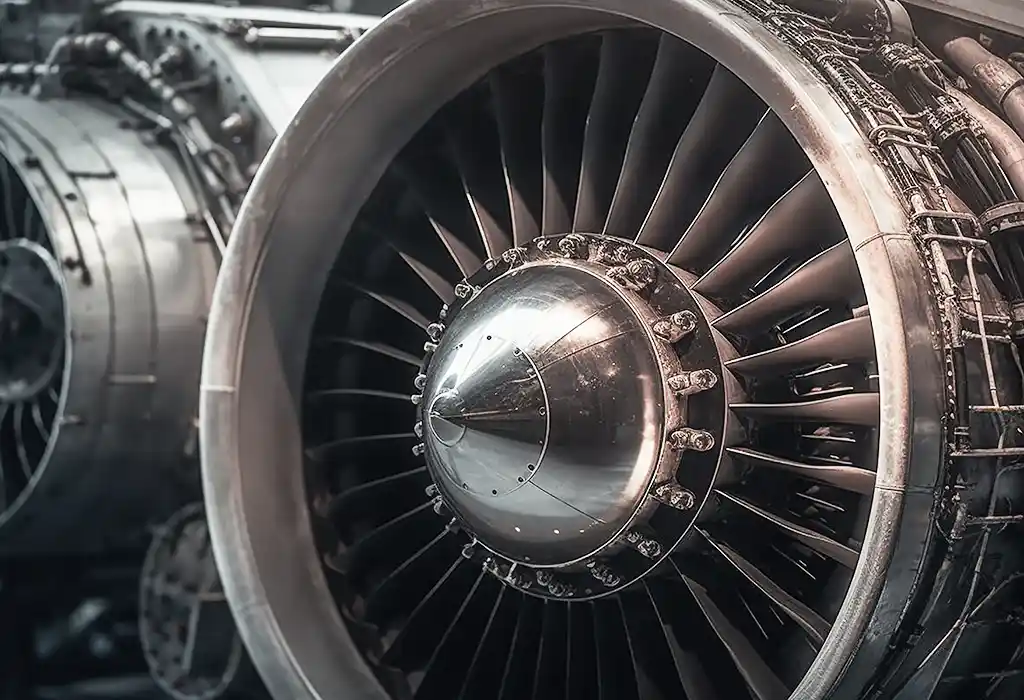

Power Generation

In fossil, nuclear, and renewable energy plants, components must withstand high heat, pressure, and corrosive media.

- Typical parts include:

- Steam and gas turbine housings

- Heat exchanger tube sheets

- Nozzle rings and flow guides

- Bearing housings

- Boiler components

Automotive

Vehicles demand lightweight and robust components that endure high mechanical loads, friction, and corrosive environments.

- Typical parts include:

- Turbocharger housings

- Exhaust manifolds and elbows

- Suspension brackets and mounts

- Gearbox and differential housings

- Sensor and control unit casings

Aviation

Aerospace systems require cast parts that are lightweight, strong, and resistant to fatigue and environmental factors.

- Typical parts include:

- Actuator housings

- Engine mounting brackets

- Hydraulic manifold blocks

- Gearbox components

- Landing gear supports

Industrial Process Equipment

Stainless steel castings satisfy hygienic, robust, and corrosion-resistant standards in food and beverage, pharmaceutical, and chemical facilities.

- Typical parts include:

- Mixer blades and agitator shafts

- Sanitary valve bodies

- Spray nozzles

- Reactor vessel fittings

- Instrument housings and flow meters

Contact Us Now

FAQs

What is the process for machining stainless steel castings?

After casting, we perform precision machining, including CNC turning and milling, to achieve the desired final dimensions, surface finish, and tolerances for each part.

Do you provide design assistance for castings?

Yes, we offer design assistance to ensure that your parts are manufacturable and cost-effective, optimizing them for both performance and production.

Are your stainless steel castings compliant with industry standards?

Yes, our castings meet global standards including EN, ASTM, JIS, and AISI, ensuring they are suitable for various international applications and regulatory requirements.

Do you offer low-volume production runs?

Yes, we provide both low-volume and high-volume production runs, tailored to meet the needs of small or large projects.

Can you provide castings in different finishes and coatings?

Yes, we offer a variety of finishes and coatings such as passivation, anodizing, and powder coating to improve durability and appearance.

How much do castings made of stainless steel cost?

The cost depends on factors like casting weight, complexity, material grade, and finishing requirements. We offer competitive pricing tailored to meet the specific needs of each project.

What industries use your stainless steel castings?

Our stainless steel castings are used in industries like automotive, aerospace, chemical processing, oil and gas, food processing, and more.

How long is the lead time for castings made of stainless steel?

Lead times typically range from 3 to 12 weeks, depending on the complexity of the casting, quantity, and required finishing, with expedited options available for urgent orders.