Forging is a crucial procedure that applies compressive forces on metal to shape it. It may, however, result in flaws that impair the finished product’s functionality and quality. These defects often result from problems with raw materials, improper forging, or insufficient post-forging treatment.

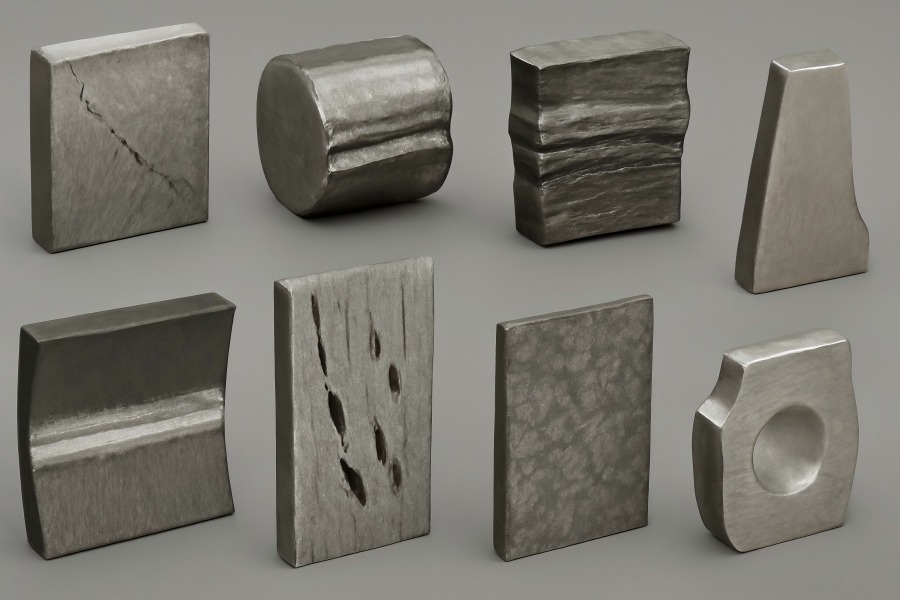

Common Forging Defects

The following section categorizes some of the most common forging defects based on their appearance, causes, and the materials affected. These defects can vary from external flaws to internal problems that weaken the material’s strength and structural integrity.

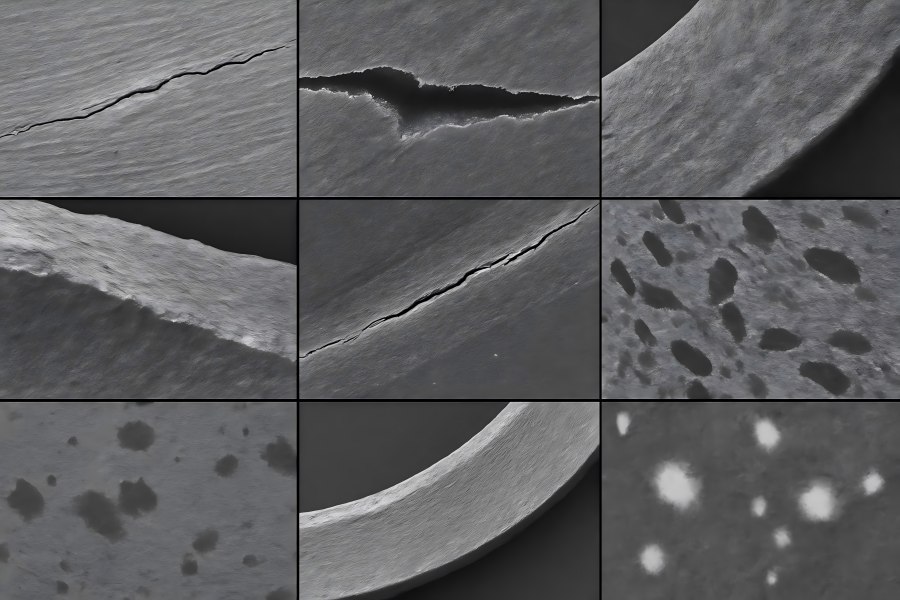

Hairline Cracks

Hairline cracks appear on the surface of the metal and are typically about 0.5 to 1.5mm deep.

- Causes: These cracks occur when the internal gas bubbles in the steel billet rupture during the rolling process, resulting from inadequate care in removing these bubbles before forging.

- Impact: If not addressed before forging, these cracks can propagate and cause severe fractures in the forged component.

- Solution: Ensure proper degassing and heating processes before forging to eliminate any internal gas bubbles and prevent the formation of hairline cracks.

Lamination

Lamination defects are characterized by the separation of layers within the material, often visible as cracks or voids within the material.

- Causes: Lamination is typically caused by the presence of non-metallic inclusions or impurities in the metal, which are elongated during the forging process. This defect often occurs in alloy steels and carbon steels.

- Impact: It leads to weakened mechanical properties and may reduce the material’s strength, particularly in the longitudinal direction.

- Solution: Use high-quality raw materials and ensure rigorous inspection and cleaning of the material before the forging process.

Scabbing

Scabbing appears as a thin, peelable film on the surface of the metal, typically around 1.5mm thick.

- Causes: Scabbing occurs due to splashing of molten steel during casting, which then cools and adheres to the surface of the billet during rolling.

- Impact: Scabbing can lead to surface defects that require additional cleaning processes.

- Solution: Enhance the cooling and cleaning processes to remove scabs from the surface of the material before it undergoes forging.

Layered Fracture

A layered fracture resembles broken slabs of stone or bark and is primarily found in alloy steels such as chromium-nickel steels.

- Causes: This defect is often caused by poor quality during the melting process, resulting in segregation of elements, gas holes, or non-metallic inclusions.

- Impact: It severely affects the mechanical properties of the material, reducing its plasticity and impact resistance.

- Solution: Proper quality control during the smelting and refining process, including thorough cleaning of the metal, is necessary to prevent the formation of non-metallic inclusions and other defects.

Bright Lines (Bright Zones)

Bright lines are shiny, reflective lines visible in the longitudinal fracture of a material, usually located in the core of the billet.

- Causes: These lines are caused by alloy element segregation within the material.

- Impact: Mild bright lines may not significantly affect the mechanical properties, but severe cases can reduce the material’s plasticity and impact strength.

- Solution: Careful control of alloy composition and ensuring uniform mixing of elements can help minimize the occurrence of bright lines.

Non-Metallic Inclusions

Non-metallic inclusions appear as broken or elongated non-metallic particles within the forged metal, often visible in longitudinal sections.

- Causes: These inclusions typically form during the melting or casting stages when there is poor control over chemical reactions between the molten metal and the furnace atmosphere.

- Impact: Inclusions weaken the material, potentially causing cracks or reducing its mechanical performance.

- Solution: Improving the melting and casting processes, such as using better refractory materials and controlling furnace gases, can reduce the presence of non-metallic inclusions.

Carbide Segregation

Carbide segregation occurs when regions within a high-carbon alloy steel contain higher concentrations of carbide particles, which are not evenly distributed throughout the material.

- Causes: This defect results from improper forging temperatures or failure to break up carbides during the forging process.

- Impact: It decreases the material’s ability to deform during forging and makes the material prone to cracking during subsequent thermal treatments.

- Solution: Optimize forging temperatures to ensure uniform distribution of carbides and improve the material’s ductility.

Aluminum Oxide Film

The aluminum oxide film is a thin, reflective layer found on the surface of forged aluminum parts, particularly near the die parting line.

- Causes: The film forms during the casting process when the molten metal comes into contact with air and reacts with moisture or other contaminants.

- Impact: The mechanical properties of the material are adversely affected, particularly when oriented perpendicular to the surface.

- Solution: Improved control of the casting environment, including reducing exposure to moisture and oxygen, will help prevent oxide film formation.

Foreign Metal Inclusions

Foreign metal inclusions occur when foreign metals are unintentionally mixed into the main metal matrix, leading to noticeable boundaries.

- Causes: These inclusions typically occur during the melting process when the furnace is contaminated with other metals or materials.

- Impact: Foreign inclusions can significantly weaken the forged part and lead to failures under stress.

- Solution: Ensure clean and controlled melting environments and prevent contamination during the forging process.

White Spots

White spots are round or oval-shaped areas that appear white or silver on the longitudinal surface of a steel billet, often indicating internal material issues.

- Causes: White spots are caused by hydrogen and phase transition-induced stress within the material during rapid cooling or improper heat treatment.

- Impact: White spots lead to brittle fractures during forging, significantly lowering the material’s ductility and strength.

- Solution: Control the hydrogen content in the steel and ensure proper cooling rates to prevent the formation of white spots.

Common Causes of Forging Defects

Most forging defects stem from one or more of the following causes:

Raw Material Defects

The quality of raw materials directly influences the outcome of the forging process. Poor-quality materials, such as those with inclusions, impurities, or improper alloy composition, can lead to various defects, including cracks, lamination, and inclusions.

Inadequate Heating

Improper heating of the billet before forging can lead to defects such as overheating or burning, which can cause grain coarsening or distortion of the metal. For the billet to be uniform, the temperature needs to be carefully regulated.

Improper Forging Techniques

The incorrect application of forging techniques, such as improper die design or insufficient or excessive force, can lead to defects like folding, improper flow lines, or internal cracks. Control over temperature, pressure, and speed during forging is essential to prevent such issues.

Inadequate Post-Forging Treatment

Post-forging treatments, including heat treatment and surface finishing, are critical for ensuring the desired properties of the material. If these processes are performed improperly, it can lead to defects such as scale formation, improper hardness, or dimensional inaccuracies.

Solutions to Prevent Forging Defects

To mitigate or prevent forging defects, manufacturers can employ the following strategies:

- Quality Control of Raw Materials: Implement stringent material inspection procedures to identify and remove defective raw materials before the forging process.

- Precise Temperature Control: Ensure accurate control of heating and forging temperatures to prevent defects like overheating, grain coarsening, or internal cracks.

- Optimized Die Design: Develop and maintain high-quality dies that promote even material flow, reducing defects related to improper flow lines or folding.

- Post-Forging Heat Treatment: Use proper heat treatment techniques to enhance the material’s strength and reduce the risk of defects like quenching cracks or thermal stress fractures.

- Regular Maintenance and Inspection: Implement regular die maintenance and thorough post-forging inspections to identify and address any defects early in the process.