Investment Casting Services

- We provide precision investment casting services that deliver near-net-shape parts with excellent dimensional accuracy and smooth surfaces.

- From design to final assembly, we offer complete, ready-to-use components tailored to your industry's performance and material needs.

- Dimensional Accuracy: ±0.1 mm -- ±2.0 mm

- Main Process Types: Silica Sol, Water Glass

- Compatible with Most Metals

- Supports Complex Part Designs

- No Flash or Parting Lines

- Environmentally Friendly Casting Process

Our Investment Casting Process

Wax Pattern Creation

Pattern Assembly

Shell Building

Wax Removal

Shell Firing

Metal Pouring

Shell Removal

Post-Casting Processing

Main Investment Casting Types

Silica Sol Investment Casting

- Silica sol binder gives tight tolerance and smooth surfaces.

- Ideal for aerospace, medical, and precision industrial applications.

- Produces complex shapes, thin walls, and reduces post-processing.

Water Glass Investment Casting

- Water glass binder fits large, simple parts needing moderate precision.

- Common in automotive, agricultural, and machinery industries.

- Supports mass production of iron and low-alloy steel parts.

Available Materials

To satisfy your unique performance, corrosion resistance, and mechanical property needs, we provide a wide range of materials:

Stainless Steel

Carbon Steel

Alloy Steel

Nickel-Based Alloys

Cobalt-Based Alloys

Aluminum Alloys

Titanium Alloys

Bronze

Copper Alloys

Dimensions in Investment Casting

| Parameter | Specification |

| Max Casting Size | Up to 1200 mm (L) × 800 mm (W) × 600 mm (H) |

| Min Casting Size | 5 mm × 5 mm × 5 mm |

| Wall Thickness | 0.5 mm – 10 mm |

| Tolerance Levels | ±0.05 mm – ±0.5 mm |

| Hole Diameter | 0.5 mm – 50 mm |

| Surface Roughness (Ra) | 0.8 – 3.2 µm |

| Aspect Ratio | Up to 10:1 |

Tolerance for Investment Casting Services

We provide precise investment casting services with strict quality standards, ensuring accurate tolerances for your specific application needs.

| Tolerance Parameter | Typical Range |

| Dimensional Tolerance | ±0.1 mm to ±2.0 mm |

| Wall Thickness Tolerance | ±0.3 mm to ±1.5 mm |

| Geometric Tolerance | ±0.1 mm to ±1.5 mm |

| Surface Finish (Ra) | Ra 0.8 to Ra 6.3 |

| Casting Defects (Porosity) | ≤ 1.5% of total volume |

| Roundness (Circularity) | ≤ 0.05 mm to ≤ 0.5 mm |

| Flatness | ±0.2 mm to ±1.0 mm |

| Parallelism | ±0.1 mm to ±0.5 mm |

| Angle Tolerance | ±0.5° to ±3.0° |

| Hole Positioning Tolerance | ±0.1 mm to ±0.5 mm |

| Casting Shrinkage | 0.3% to 2.0% |

| Metal Flow Control | ±0.5 mm to ±2.0 mm |

| Radii and Fillets | ±0.1 mm to ±0.3 mm |

| Core Shifting | ≤ 0.3 mm |

| Internal Surface Finish (Ra) | Ra 1.6 to Ra 3.2 |

| Corner Radius | ±0.2 mm to ±1.0 mm |

| Thickness Variability | ±0.5 mm to ±1.5 mm |

| Casting Alignment Tolerance | ±0.2 mm to ±1.0 mm |

| Length and Width Tolerance | ±0.1 mm to ±2.0 mm |

Post-Casting Processing

Heat Treatment

Performed in furnaces like annealing, quenching, tempering, and solution to enhance structure, hardness, and mechanical performance of castings.

Surface Finishing

Includes shot/sand blasting, pickling, passivation, and alkali cleaning to remove oxide scales and improve stainless steel casting surfaces.

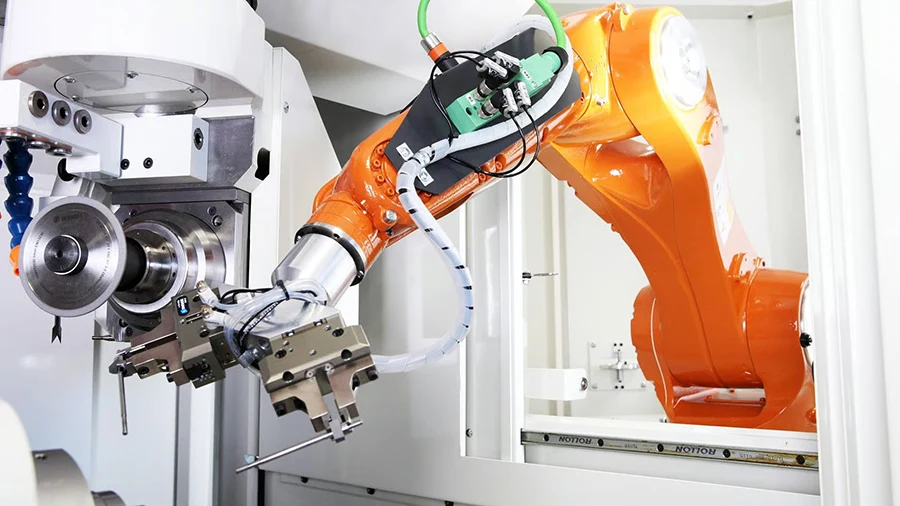

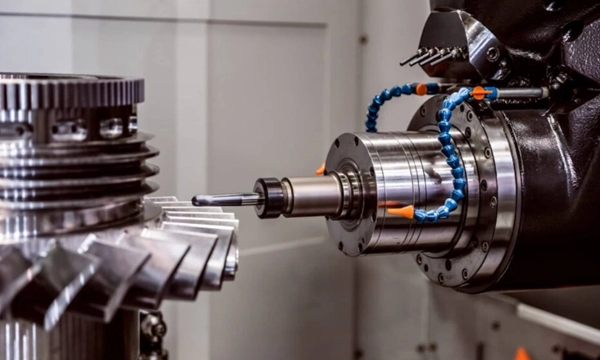

Machining

Utilizes CNC lathes, milling, and drilling to achieve required precision, tolerance, and surface finish for functional casting applications.

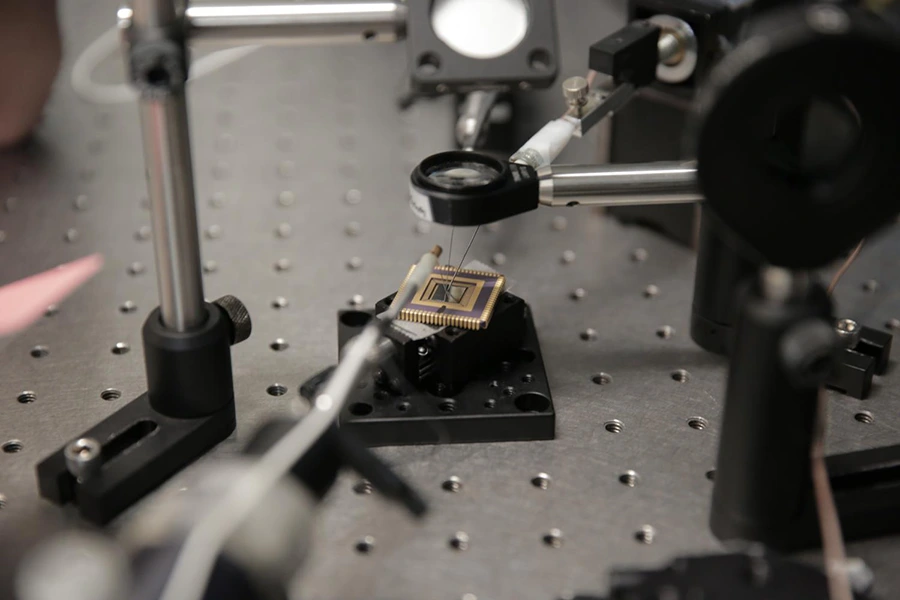

NDT Testing

Dye penetrant, ultrasonic, and X-ray testing detect internal or surface defects without damaging the casting’s structural integrity or appearance.

Welding

TIG welding is applied to repair minor casting defects within standards, ensuring reliable strength, surface integrity, and dimensional accuracy.

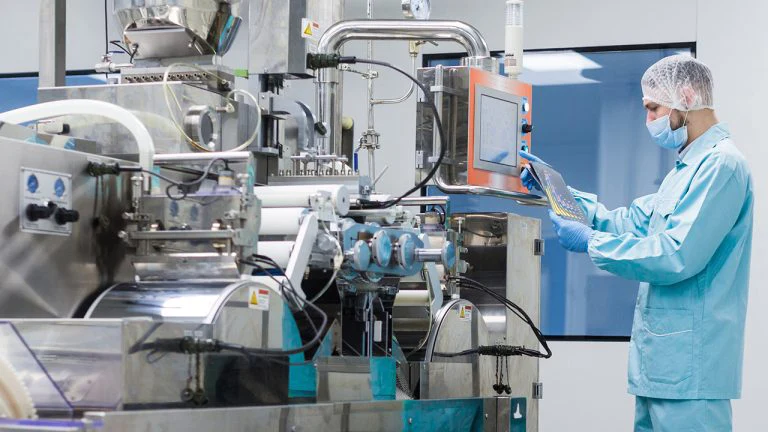

Assembly & Fitting

Components are fitted or assembled into complete units, ensuring compatibility, function, and readiness for final application or customer delivery.

Inspection Techniques

We implement rigorous inspection techniques to ensure casting accuracy, structural integrity, and compliance with material and performance standards.

Dimension Inspection

Appearance Inspection

Internal Quality Inspection

Mechanical Properties Testing

Chemical Composition Analysis

Metallographic Analysis

Our Investment Casting Parts

Applications

Our investment casting supports complex, high-performance parts across industries, offering precision, strength, and versatility in diverse critical applications.