Forged Metal Discs

- Precision-crafted for strength, nonmagnetic and non-toxic, our custom forged discs offer superior grain structure, tight tolerances, and material flexibility.

- Designed for demanding applications, they deliver top performance in vessels, turbines, valves, and structures. Custom sizes and finishes match your specifications.

- Custom Drilling and Machining Per Drawings

- Supports Various Hole Shapes and Configurations

- Handles Complex Grooving and Chamfering

- ISO9001, PED, and SGS Certified

By Design

The flat, solid, slotted, and tube sheet forged discs in our design can be customized in terms of size, material, and application-specific setups.

Flat Discs

- Uniform, smooth, ideal for welding and rotating load applications.

- Used in vessels, exchangers, reactors, valves, and structural supports.

- Custom diameter, thickness, bore, and surface finish options.

Slotted Discs

- Slots enhance cooling, flow, and reduce disc weight.

- Applied in brakes, turbines, and clutch assemblies.

- Custom slot size, number, pattern, and material.

Tube Sheet Discs

- Forged with holes for mounting tubes in exchangers.

- High sealing, strength, corrosion resistance under heat.

- Custom hole layout, thickness, and alloy grade.

By Material

We offer forged discs in a wide range of metal materials, each engineered for specific strength, corrosion resistance, and temperature performance.

Carbon Steel Discs

Made from A105, C45, or Q235 carbon steel. Offers excellent machinability, weldability, moderate strength, and cost-effective forging performance.

Stainless Steel Discs

Forged from 304, 316, or 410 stainless steel. Provides corrosion resistance, durability, high strength, and clean surface finish after forging.

Alloy Steel Discs

Utilizes 42CrMo4, 20CrMnTi, or 34CrNiMo6, delivering toughness, wear resistance, and high fatigue strength under demanding thermal and mechanical conditions.

Die Steel Discs

Made from H13, D2, or SKD11 die steel. Known for high hardness, thermal fatigue resistance, and dimensional stability in forging.

Aluminum Discs

Forged using 6061, 7075, or 2024 aluminum alloy. Lightweight, resistant to corrosion, with great strength-to-weight ratio and excellent formability.

Titanium Discs

Produced from Grade 2, Grade 5 (Ti-6Al-4V), or Grade 23. Offers low density, high corrosion resistance, and exceptional strength-to-weight performance.

Applications

Our forged metal discs are precision forged to exacting standards, making them ideal for a variety of high-demand applications across major industrial sectors.

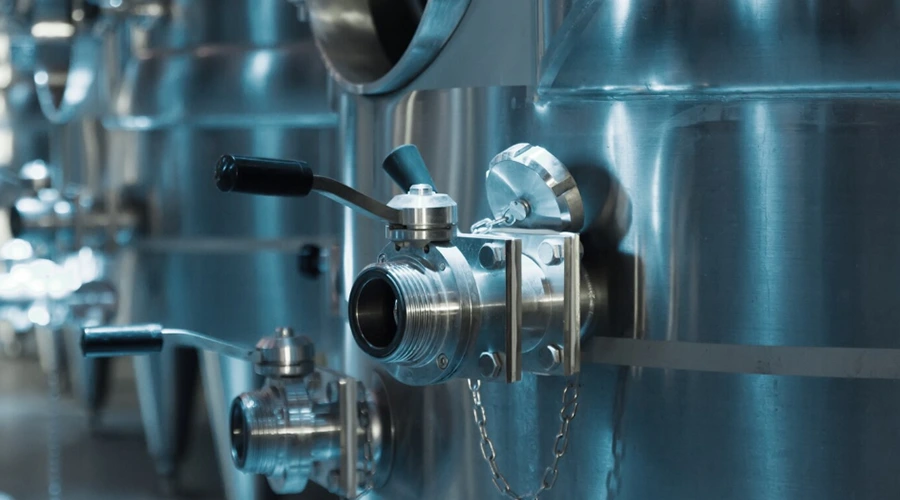

Vessel & Boiler Manufacturing

Forged metal discs are applied in pressure vessels, steam boilers, and autoclaves for their strength under extreme temperature and pressure conditions.

Heat Transfer Equipment

Ideal for condensers, evaporators, heat exchangers, and tube sheets, forged discs ensure thermal stability and corrosion resistance in high-efficiency systems.

HVAC and Cooling Systems

Commonly used in central air conditioners and industrial cooling units where reliable, long-lasting forged metal discs are required for performance and safety.

Heavy Industry & Infrastructure

Forged discs support structural integrity in bridges, cranes, mining machinery, and offshore platforms, delivering durability and shock resistance in harsh environments.

Energy Sector Applications

Utilized in power generation, oil and gas, and renewable energy systems for their strength, fatigue resistance, and ability to handle mechanical loads and thermal cycles.