Custom Metal Casting Services

- Our metal casting services deliver precision mechanical parts tailored to your exact requirements, effectively tackling complex geometries, tight tolerances, and material strength demands.

- We offer CNC post-processing for high-precision components, ensuring outstanding surface finishes and rapid delivery to support your project goals.

- Various Casting Process Types

- Dimensional tolerance: ±0.05–0.20 mm

- Suitable for Ferrous and Non-ferrous Metals

- Supports Complex Geometries

- Diverse Surface Treatment Options

Our Casting Process

Prototyping

We use CAD software and CNC machining to create precise prototypes tailored to each client’s casting design.

01

Module Manufacturing

Wax is injected into molds, trimmed, cleaned, and assembled onto gating systems to form wax pattern trees.

02

Shell Making

Pattern trees are repeatedly coated with ceramic slurry and refractory sand, then dried to form a strong shell.

03

Dewaxing

High-pressure steam, hot water, or microwave systems remove wax from the shell, leaving a clean internal cavity.

04

Shell Baking

Shells are fired at 1000–1150°C in kilns to remove residues and strengthen mold structure for casting.

05

Melting and Pouring

Alloys are melted in suitable furnaces and poured into heated shells using ladles, vacuum, or centrifugal systems.

06

Post-Processing

Shells are removed; castings are cut, cleaned, ground, heat treated, chemically treated, and welded if necessary.

07

Inspection and Testing

Dimensional checks, flaw detection, mechanical testing, and composition analysis ensure castings meet required quality standards.

08

Based on Mold Type

Methods for permanent, disposable, and composite mold casting provide flexibility for sophisticated, high-volume, or prototype castings in a variety of sectors.

Permanent Mold Casting

- Employs reusable metal molds for consistent, high-volume production.

- Ensures high accuracy, smooth finish, and fast cooling.

- Suitable for aluminum, magnesium, and copper alloy casting.

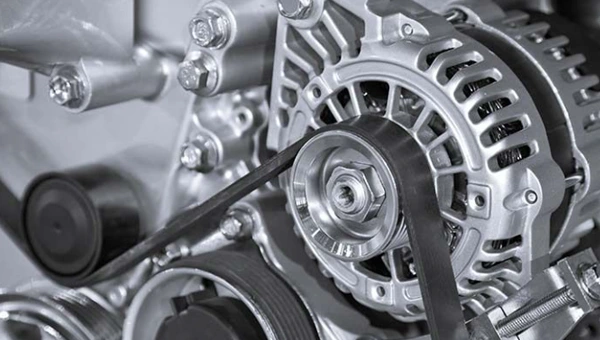

- Common in automotive, aerospace, and industrial applications.

Expendable Mold Casting

- Uses temporary molds like wax, plaster, or ceramic.

- Ideal for low-volume, complex, or prototype castings.

- Includes investment and lost foam casting methods.

- Fits ferrous, non-ferrous metals in industrial applications.

Composite Mold Casting

- Combines permanent molds with expendable cores.

- Balances cost, precision, and design flexibility.

- Enables intricate cores in reusable mold setups.

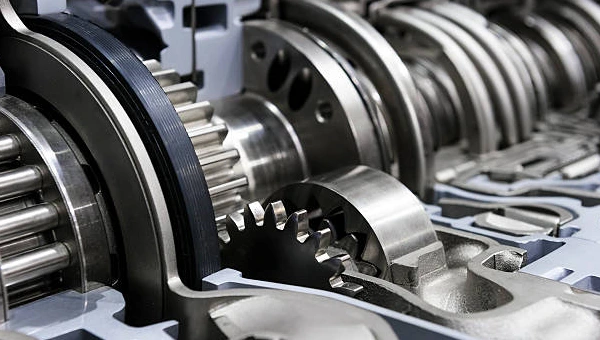

- Used in complex engine and structural castings.

Based on Casting Process

- Uses gravity to fill metal into permanent molds.

- Ideal for thick-walled parts with high structural strength.

- Best for aluminum and copper alloy components.

- Used in automotive, plumbing, and heavy machinery.

Shell Mold Casting

- Uses resin-coated sand for high-precision shell molds.

- Enables thin-walled shapes with excellent surface finish.

- Best for medium to high-volume precise casting.

- Used in automotive, aerospace, and gear production.

- Uses wax patterns and ceramic molds for precision casting.

- Water glass casting offers affordable accuracy for non-critical parts.

- Suitable for complex, detailed parts with minimal waste.

- Common in aerospace, dental, and turbine parts.

- Injects molten metal into steel molds under pressure.

- Produces smooth, accurate parts at high production speed.

- Best for low-melting-point non-ferrous metals.

- Ideal for automotive, electronics, and appliance components.

Available Metal Materials

Iron

- Ductile iron is strong, flexible, ideal for structural cast parts.

- Grey iron offers damping, conductivity, and easy machining for components.

- Iron castings are affordable, machinable, widely used in heavy industry.

Steel

- Carbon steel is tough, economical, used in general structural parts.

- Alloy and tool steel are hard, wear-resistant, suitable for tools.

- Stainless steel resists corrosion, heat, great for medical and food.

Aluminum

- Lightweight, corrosion-resistant aluminum suits electronics and mechanical devices.

- Aluminum allows precision casting with clean finish and tight tolerances.

- Lowers weight and boosts performance in appliances and industrial designs.

Copper

- Brass is strong, corrosion-resistant, ideal for fittings and decorations.

- Bronze is durable, wear-resistant, perfect for marine and bearings.

- Copper alloys conduct electricity and heat for plumbing and electronics.

Surface Treatment

Hot-dip Galvanizing

Creates a strong, protective layer by submerging components in molten zinc, which offers long-lasting corrosion prevention.

Zinc Plating

Electroplated zinc coating enhances corrosion resistance, improves aesthetic appearance, and provides a protective layer for metals.

Chrome Plating

A thin chromium layer applied for a shiny finish, increased wear resistance, and improved corrosion protection.

Spray Painting

Uses a sprayer to apply a consistent layer of paint, protecting the surface and improving its appearance.

Powder Painting

Durable, environmentally friendly coating applied as a dry powder, offering a tough, smooth finish with excellent protection.

Polishing

Achieves a smooth, reflective surface finish through abrasion, enhancing the aesthetic appeal and reducing friction.

Anodizing

Electrolytic process enhances metal's natural oxide layer, increasing corrosion resistance and providing color and texture options.

Black Oxide

Adds a black, corrosion-resistant coating to metal surfaces, providing a matte finish with increased durability.

Tolerance for Casting Services

We offer precision casting services with strict control over critical tolerances to meet the demands of diverse industries. Our standard tolerance ranges are as follows:

| Parameter | Tolerance Range |

| Dimensional Tolerance | ±0.05 mm to ±2.00 mm |

| Surface Finish | Ra 0.8 µm to Ra 6.3 µm |

| Weight Tolerance | ±0.5% to ±2% |

| Wall Thickness | ±0.3 mm to ±1.5 mm |

| Straightness | 0.1 mm to 0.3 mm per 100 mm |

| Flatness | 0.1 mm to 0.5 mm per 100 mm |

| Roundness | 0.1 mm to 0.25 mm |

| Core Shift | ±0.05 mm to ±0.3 mm |

| Porosity (Volume %) | Less than 0.5% |

| Thread Tolerance | ±0.2 mm to ±0.5 mm |

| Draft Angle | 1° to 5° |

| Casting Shrinkage | 1% to 3% |

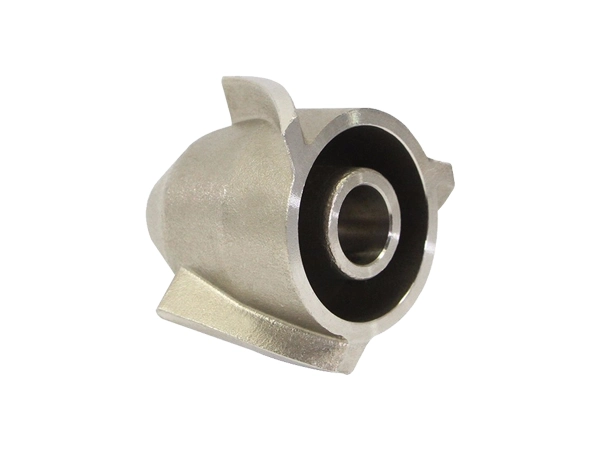

Our Projects

Stainless Steel Casting

Carbon Steel Castings

Alloy Steel Castings

Aluminum Castings

Special Material Castings

- Made from stainless steel and iron.

- 304, 304L/316L, 316 cover diverse needs.

- Supports complex internal and external designs.

- Suitable for wide industrial applications.

- Supports stainless, carbon, duplex, aluminum casting.

- Flexible in shape, size, and weight.

- Investment casting from 0.001kg to 99kg.

- Sand casting supports up to 500kg.

- Compatible with various metal materials.

- 304 suitable for food and medical.

- 304L supports welding, resists high temperature.

- 316 ideal for offshore and valves.

- Supports multiple global material standards.

- Compatible with various carbon steel grades.

- Minimizes need for secondary machining.

- Suitable for demanding structural applications.

- Compatible with diverse steel materials.

- Handles water, steam, oil, corrosives.

- Serves power, marine, nuclear applications.

- Includes many valve type options.

- Offers various surface treatment options.

- Zinc and chrome plating available.

- Provides near-net-shape casting results.

- Suitable for marine and gardening use.

- Precision machining up to ±0.009mm.

- Surface roughness reaches Ra1.6–3.2.

- Minimum casting thickness just 0.5mm.

- Offers both sand and steel casting.

- Supports stainless and specialty alloy materials.

- Materials include 35SiMn to 38CrMoAI.

- Available in four impeller types.

- Suitable for hardware and machinery industries.

- Compatible with various metal materials.

- Suitable for complex and intricate designs.

- Offers excellent precision and surface smoothness.

- Customizable based on client specifications.

- Compatible with multiple ADC alloy grades.

- Easier modular assembly and complex shaping.

- Widely used in automotive and aerospace industry.

- Ideal for transport and power machinery.

- Supports easier modular design and assembly.

- Suitable for welding and fabrication needs.

- Popular in aviation and transport machinery.

- Compliant with GB/T 15115 standards.

- Compatible with various ADC aluminum alloys.

- Supports welding and post-processing operations.

- Enables thin thickness and complex shaping.

- Machinable with good dimensional accuracy.

- Excellent corrosion resistance in harsh environments.

- Minimum thickness can reach 0.5mm.

- Dimension flexibility up to 1500mm.

- Suitable for both sand and precision casting.

Application

Chemical & Petrochemical

Precision cast parts used in the production of industrial equipment, valves, pumps, and reactors for the chemical and petroleum industries.

Marine & Shipbuilding

High-performance castings for ship hulls, engines, and propulsion systems, ensuring durability and corrosion resistance in harsh marine environments.

Energy & Power Generation

Custom castings for turbines, generators, pumps, and other critical components, supporting efficient power generation and energy production systems.

Industrial Equipment Manufacturing

High-strength castings for machinery, tools, and automation systems used across various industrial applications, enhancing performance and longevity.

Environmental Technology

Robust casting solutions for filtration, waste management, and recycling equipment, contributing to sustainable environmental technologies and processes.

Mining & Excavation

Durable cast parts for mining equipment, including crushers, excavators, and conveyors, designed to withstand extreme wear in mining operations.

Automotive & Transportation

Advanced castings for automotive parts, engines, and transportation systems, ensuring reliability and safety in high-demand applications.

Aerospace & Defense

Precision metal castings for critical aerospace and defense components, ensuring reliability, high performance, and safety in mission-critical systems.