Metal Flanges Manufacturer

- We forged high-quality stainless, carbon, alloy, and duplex steel flanges with diameters up to 6.6 meters, serving energy, petrochemical, shipbuilding, and machinery industries.

- Certified by ISO9001 and TUV, our precision forging and finishing processes ensure accuracy up to ±0.009mm, supporting both standard and customized solutions.

- Wide Material Options

- Multiple Connections and Face Type

- Pressure Rating: Class 150, 300, 600, 900, 1500, 2500

- Standards: DIN, ANSI, JIS, EN, BS, GB, etc.

- Flexible Manufacturing With Fast Lead Times

By Materials

Each metal flange type is manufactured to specific industry and performance requirements and is available in a variety of material options.

- Strong economical flange for high-temperature and pressure systems.

- ASTM A105 A350 LF2 A694 F52 models.

- Used in pipelines refineries power plants shipbuilding industries.

- Withstands corrosion in extreme environments.

- Popular stainless models include ASTM A182 F304 F316 F321.

- Applied in food chemical pharmaceutical and marine equipment.

- High strength heat-resistant flange for demanding applications.

- ASTM A182 F11 F22 F5 preferred alloy models.

- Used in reactors thermal power chemical processing systems.

- High yield strength corrosion-resistant for chloride-rich environments.

- ASTM A182 F51 F53 F55 suit marine service.

- Used in desalination offshore oil and chemical plants.

- Titanium Alloy flanges offer corrosion resistance and low weight.

- Grade 2 Grade 5 ANSI JIS DIN compliant.

- Common in aerospace marine desalination chemical vessel systems.

- Nickel Alloy flanges endure heat corrosion and aggressive media.

- Includes Copper-Nickel Flange and Monel 400 flanges.

- Used in petrochemical marine power heat exchanger fields.

- Cost-effective damping flange for general pipeline connection use.

- Gray iron ductile iron GJL-250 GJS-400 available.

- Common in HVAC drainage municipal and low-pressure pipelines.

- Lightweight corrosion-resistant flange for industrial structural applications.

- Grades 6061-T6 5083 7075 widely adopted types.

- Applied in HVAC auto food and compressed air systems.

By Connection Method

Our forged flange connection types include welding, threading, or rotating designs, offering flexible, leak-proof, application-specific solutions across standard, high-pressure, and specialty systems.

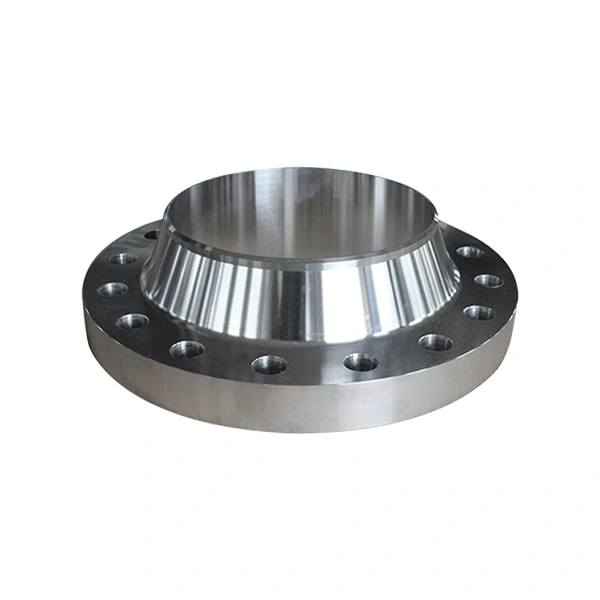

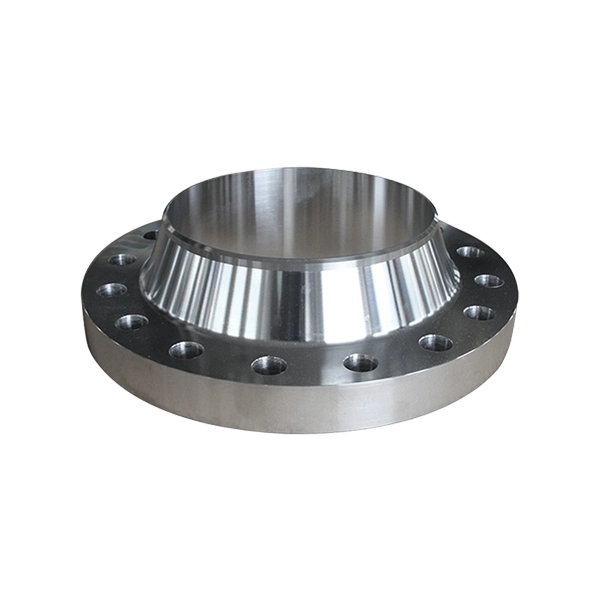

- Tapered hub strengthens connection for high-pressure pipeline use.

- Applied in petrochemical, oil, gas, and energy systems.

- Welded securely to pipe ensuring leak-free sealed joints.

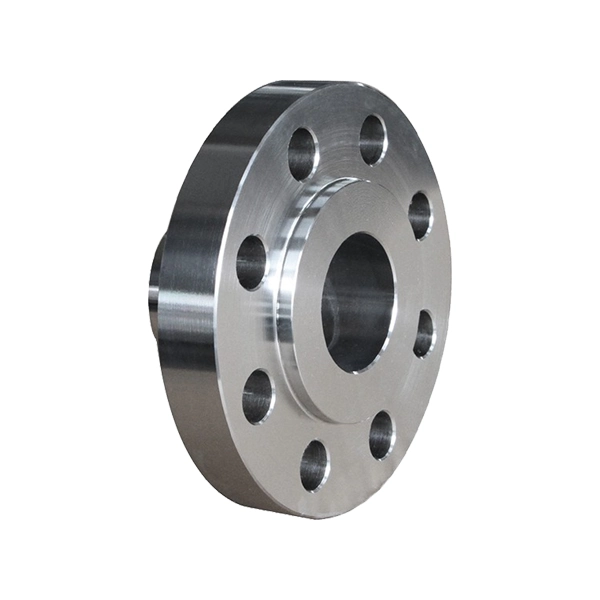

- It is welded inside and outside, sliding over the pipe.

- Ideal for low-pressure, water supply, and HVAC applications.

- Easier alignment and quick disassembly during maintenance.

- Pipe inserted into socket for single-side fillet weld.

- Ideal for small-diameter high-pressure hydraulic process piping.

- Available with or without neck, minimal welding deformation.

- Internal threads eliminate welding for safe pipe connection.

- Common in cooling lines and high-pressure pipelines.

- Easy installation and removal in hazardous welding environments.

- Paired with stub end to align rotating flange.

- Used in pharmaceutical, food-grade, clean processing systems.

- Low-cost option with expensive corrosion-resistant pipe systems.

- Solid plate seals pipe end or vessel opening.

- Withstands internal pressure during testing and flow isolation.

- Allows easy system access for repair or inspection.

- Measures fluid flow with installed orifice plate set.

- Used in chemical, oil, and gas flow monitoring.

- Includes taps, gaskets, bolts, and jackscrews kit.

- Rotating ring eases bolt hole alignment during installation.

- Perfect for subsea, offshore, and floating pipe applications.

- Enables repeated alignment in tight or remote areas.

By Face Type

The FF, RF, RTJ, T&G, and M&F flange face types provide sealing options for a range of pressure, temperature, and alignment application needs.

Flat Face (FF) Flange

- Features a flat sealing surface for full gasket contact.

- Commonly used in low-pressure, low-temperature piping systems.

- Ideal for cast iron and fiberglass piping connections.

Raised Face (RF) Flange

- Most commonly used flange face design in industries.

- Raised surface concentrates pressure on the gasket area.

- Suitable for high-pressure, high-temperature process systems.

Ring Type Joint (RTJ) Flange

- Contains a precision-machined groove for metal ring gasket.

- Ensures leak-proof sealing in extreme pressure applications.

- Often used in petrochemical and offshore environments.

Tongue and Groove (T&G) Flange

- Matching tongue and groove for gasket alignment and sealing.

- Prevents gasket displacement during installation.

- Suitable for critical applications needing tight alignment.

Male and Female (M&F) Flange

- One flange has raised (male), the other recessed (female) face.

- Provides better gasket retention than flat surfaces.

- Used in heat exchangers, compressors, and pump connections.

By Design

Integral, expander, reducer, and long weld neck flange designs are offered, guaranteeing strength, size transition, effectiveness, and pressure resilience in difficult applications.

Integral Flange

Combines the flange and pipe into one solid piece for strength. Common in high-pressure applications where maximum structural integrity is required.

Expander Flange

Designed to enlarge the pipe diameter at the flange joint. Ideal for pipeline transitions without using a separate reducer and welding operation.

Reducer Flange

Connects different pipe sizes with a built-in reducer design. Eliminates the need for separate reducers, saving installation space and welding costs.

Long Weld Neck Flange

Includes an extended neck to strengthen high-pressure, high-temperature systems. Common in refineries and chemical plants for secure, stress-distributing connections.