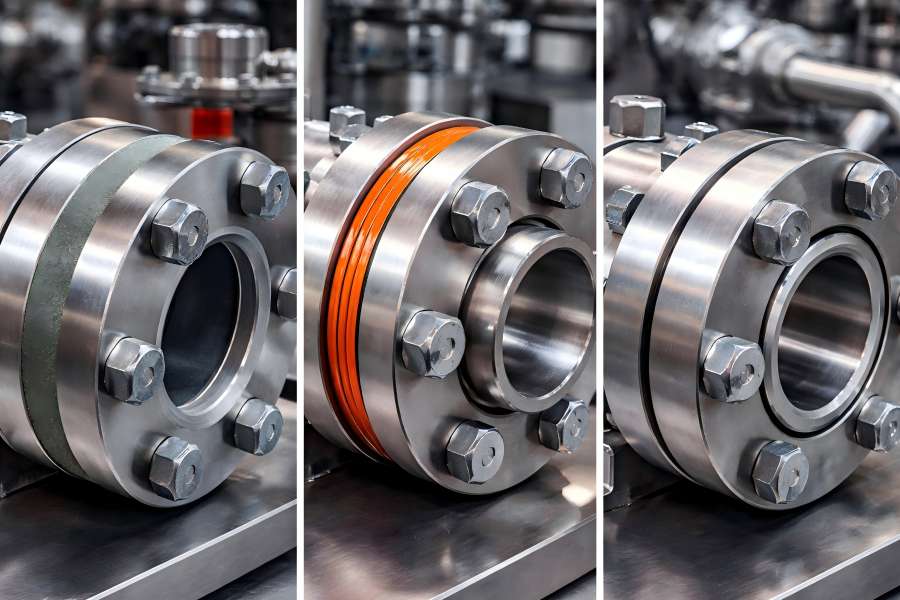

Choosing the correct flange sealing face is a critical engineering decision in high-pressure piping systems, directly affecting safety, leakage control, and long-term operational reliability. Flat Face (FF), Raised Face (RF), and Ring-Type Joint (RTJ) flanges are among the most often specified alternatives; each fulfills certain pressure and service requirements.

Understanding Flange Sealing Faces in High-Pressure Systems

A flange sealing face is the contact surface where a gasket or metal ring creates a seal between two flanged components. In high-pressure systems, this interface must withstand internal pressure, temperature fluctuations, mechanical vibration, and chemical exposure without leakage or structural degradation.

The effectiveness of a sealing face depends on several factors, including contact area, gasket type, surface finish, bolt preload, and material compatibility. As operating pressure increases, sealing demands shift from broad, soft gasket compression toward concentrated, high-stress sealing mechanisms that can resist blowout and deformation.

Flat Face, Raised Face, and Ring-Type Joint designs represent three progressively stronger sealing philosophies, each optimized for specific pressure ranges and system conditions.

What Is a Flat Face (FF) Flange?

A flat face flange features a sealing surface that is level with the bolt circle. When two FF flanges are bolted together, the gasket is compressed uniformly across the entire flange face.

This design distributes compressive stress over a wide area, reducing localized stresses on the flange and bolts. FF flanges are commonly paired with full-face gaskets that extend to the outer edge of the flange.

Advantages of FF Flanges

Flat Face flanges offer several practical advantages in low-stress environments:

- Uniform gasket compression reduces the risk of flange distortion

- Compatibility with softer gasket materials

- Simplified alignment during installation

- Lower manufacturing and machining costs

Because of their forgiving geometry, FF flanges are often preferred when flange material strength is limited.

Limitations in High-Pressure Applications

Despite their simplicity, FF flanges are not ideal for high-pressure service:

- Lower sealing stress per unit area

- Increased likelihood of gasket creep under pressure

- Higher risk of leakage when pressure or temperature fluctuates

- Not suitable for metal gaskets or extreme operating conditions

As pressure increases, the large sealing area becomes a disadvantage, as it reduces effective gasket seating stress.

Typical Applications

Flat face flanges are frequently utilized in:

- Low-pressure water pipelines

- HVAC systems

- Fire protection networks

- Cast iron piping systems

- Utility and non-critical service lines

In high-pressure projects, FF flanges are usually avoided unless system pressure is strictly limited.

What Is a Raised Face (RF) Flange?

A raised face flange has a sealing surface positioned above the bolt circle. This raised portion concentrates gasket compression in a smaller area, improving sealing performance compared to Flat Face designs.

Raised Face heights are standardized according to pressure class and specification, most commonly defined by ASME B16.5 and B16.47.

Advantages of RF Flanges

Raised Face flanges are the most widely used flange type in industrial piping due to their balance of performance and flexibility:

- Higher gasket seating stress improves sealing reliability

- Compatible with soft, semi-metallic, and spiral-wound gaskets

- Suitable for moderate to high-pressure applications

- Standardized across multiple pressure classes

RF flanges perform well across a broad range of operating conditions, making them a default choice for many engineers.

Pressure and Temperature Performance

Compared to FF flanges, RF flanges tolerate higher pressures and temperatures. However, their performance depends heavily on gasket selection and bolt preload accuracy. At very high pressures, gasket extrusion or blowout can occur if improper gasket materials are used.

Common Applications

Raised Face flanges are widely applied in:

- Processing of oil and gas

- Petrochemical and chemical plants

- Power generation facilities

- Industrial steam systems

- Refining and midstream pipelines

For many high-pressure projects below extreme service thresholds, RF flanges provide an optimal balance between cost and performance.

What Is a Flange for a Ring-Type Joint (RTJ)?

Ring-Type Joint flanges utilize a precision-machined groove that houses a solid metal ring gasket. When bolted together, the ring is plastically deformed, creating a metal-to-metal seal.

Unlike FF and RF designs, RTJ flanges do not rely on gasket compression alone. Instead, they generate extremely high localized sealing stress capable of withstanding severe pressure and temperature conditions.

Advantages of RTJ Flanges

RTJ flanges are engineered specifically for extreme service environments:

- High resistance to thermal cycling and vibration

- Exceptional sealing performance at very high pressures

- Minimal risk of gasket blowout

- Reliable metal-to-metal sealing

Once properly installed, RTJ connections offer unmatched leakage control in critical systems.

Limitations and Cost Considerations

Despite their performance advantages, RTJ flanges have notable drawbacks:

- Higher manufacturing and machining costs

- Requirement for precision installation

- Limited gasket reusability

- Not compatible with lower-pressure flange faces

Typical High-Pressure Applications

RTJ flanges are commonly specified in:

- High-pressure steam pipelines

- Upstream oil and gas production

- Refinery hydrocracking units

- Offshore and subsea systems

- High-temperature, high-pressure chemical reactors

FF vs RF vs RTJ: Technical Comparison

The following table highlights key technical differences among the three sealing face types.

| Parameter | FF Flange | RF Flange | RTJ Flange |

| Sealing Method | Full-face gasket compression | Concentrated gasket compression | Metal ring deformation |

| Sealing Stress | Low | Medium to high | Very high |

| Pressure Capability | Low | Medium to high | Extremely high |

| Temperature Capability | Limited | Moderate | Severe service |

| Leakage Risk | Higher | Moderate | Lowest |

| Gasket Types | Soft full-face | Soft, spiral-wound | Solid metal rings |

| Installation Complexity | Low | Moderate | High |

| Typical Cost | Lowest | Medium | Highest |

Key Factors Affecting Sealing Performance in High-Pressure Projects

Gasket Material Selection

Gasket material must match both the flange face and operating conditions. Soft gaskets suit FF flanges, spiral-wound gaskets pair well with RF flanges, while RTJ flanges require precisely machined metal rings.

Surface Finish and Flatness

Sealing faces must meet specified surface roughness requirements. Excessively smooth surfaces may cause gasket slippage, while rough surfaces can damage gaskets and compromise sealing.

Bolt Preload and Torque Control

Insufficient bolt preload leads to leakage, while excessive torque risks flange or bolt failure. RTJ flanges are particularly sensitive to accurate torque application.

Thermal Cycling and Vibration

Repeated temperature changes can relax bolt tension and degrade gasket materials. RTJ flanges offer superior resistance to these effects due to their metal-to-metal sealing mechanism.

Standards and Codes Governing Flange Sealing Faces

International standards control flange application and design to provide interoperability and safety. Commonly referenced standards include:

- ASME B16.5 and B16.47 for dimensional and pressure ratings

- API specifications for high-pressure and critical service

- ISO standards for global system compatibility

Compliance with these standards is essential in high-pressure projects to meet regulatory and safety requirements.

Selecting the Right Sealing Face for High-Pressure Projects

Selecting the ideal flange face requires weighing several considerations:

- Maximum operating pressure and temperature

- Media characteristics, including corrosiveness

- Safety and environmental risk tolerance

- Maintenance accessibility and lifecycle cost

Practical Selection Guidance

- FF flanges suit low-pressure, non-critical systems

- RF flanges cover most industrial high-pressure needs

- RTJ flanges are essential for extreme pressure and critical service

Engineering judgment, supported by standards and system analysis, is essential when making the final selection.