Pipe fittings are small components, but they often decide whether a piping system stays tight and safe—or develops leaks and failures. Among the many fitting types, wrought fittings and forged fittings are two of the most widely used in industrial piping.

Understanding how they differ in structure, performance, and installation is essential for engineers and buyers who want long-term strength and leak integrity.

Wrought vs Forged Fittings

What are wrought fittings?

In piping, wrought fittings are typically formed from pipe, tube, or plate that has already been worked (rolled, extruded, or drawn). The word “wrought” simply means the metal has been plastically worked rather than cast directly from molten metal.

Typical wrought fittings include:

- Butt-weld elbows (short radius and long radius)

- Tees and reducing tees

- Concentric and eccentric reducers

- Caps and stub ends

These are generally governed by standards such as ASME B16.9 and material specifications like ASTM A234 (carbon/alloy steel) and ASTM A403 (stainless steel). Many are made from seamless pipe or plate that is hot formed and then heat treated.

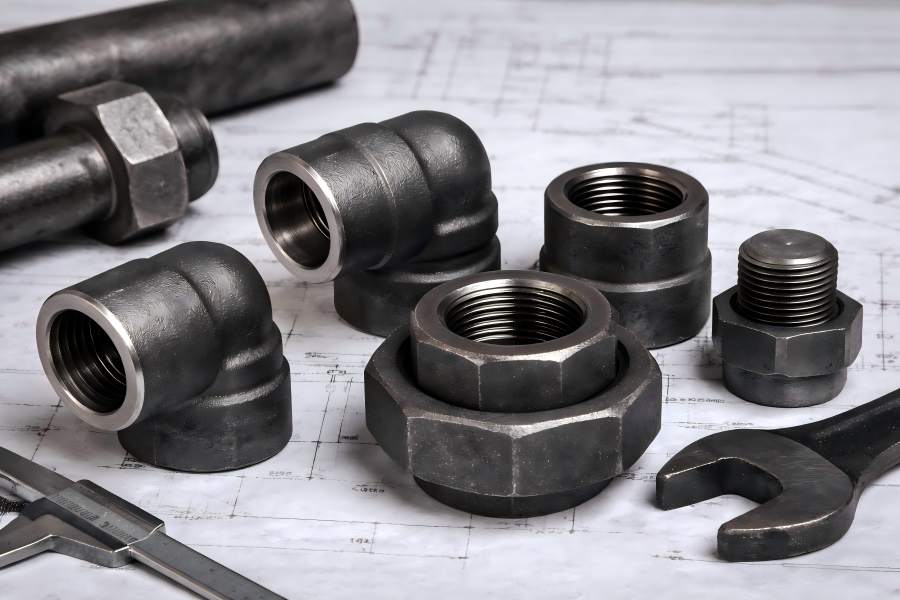

What are forged fittings?

Forged fittings are produced from solid billets or bars that are heated and deformed into shape by forging presses or hammers. After forging, the parts are machined to final dimensions.

Common forged fittings include:

- Socket weld elbows, tees, and couplings

- Threaded elbows, tees, couplings, and plugs

- Unions, caps, and outlets (e.g., weldolets, sockolets)

These are typically covered by ASME B16.11, with materials such as ASTM A105, A182, and other forged grades.

Where they sit in the standards landscape

- Wrought buttweld fittings → ASME B16.9 + ASTM A234 / A403 / A420, etc.

- Forged fittings (socket/threaded) → ASME B16.11 + ASTM A105 / A182, etc.

Both families can serve in critical services, but they are optimized for different sizes, pressure ratings, and connection types.

How Forged and Wrought Fittings Are Produced

The manufacturing route directly shapes the metal’s microstructure and the potential leak paths.

Wrought fitting manufacturing route

Typical steps for wrought butt-weld fittings:

- Start from pipe, tube, or plate (seamless or welded).

- Hot forming using induction bending, pressing, or extrusion.

- A longitudinal seam is created by rolling and welding the plate at some large diameters.

- Heat treatment to restore toughness and relieve stress.

- Final machining and dimensional finishing.

Because wrought fittings are formed from pre-worked materials, the base metal often has a refined grain structure and good toughness. However, when welded seams are present, they introduce heat-affected zones (HAZ) and potential defect locations.

Forged fitting manufacturing route

Typical steps for forged fittings:

- Cut billets or bars to length.

- Heat to a forging temperature.

- Use open-die or closed-die forging to form rough shape.

- Trim flash and forge further if needed for contours.

- Heat treat to achieve required mechanical properties.

- Machine internal bores, threads, and socket weld ends.

Forging compresses the metal and aligns grains to follow the part’s geometry, creating a dense, compact, and usually defect-lean structure.

Process comparison table

Table 1 – Manufacturing Route: Wrought vs Forged Fittings

| Aspect | Wrought Fittings | Forged Fittings | Effect on Performance |

| Starting material | Pipe, tube, or plate (rolled/wrought) | Solid billet or bar | Both start from worked stock; forging adds further working |

| Forming method | Hot forming, bending, pressing, sometimes welding | Hot forging under high pressure | Forging introduces stronger directional grain flow |

| Possible welds | Longitudinal seams or weld buildups on some sizes | No longitudinal seam in body (solid section) | Welds can be potential leak or crack locations |

| Typical connection | Butt weld to pipe | Socket weld or threaded joint | Different leak paths and installation methods |

| Main standards | ASME B16.9, ASTM A234/A403, etc. | ASME B16.11, ASTM A105/A182, etc. | Each governed by its own dimensions and testing |

Metallurgy and Mechanical Strength

Grain structure in wrought fittings

Wrought fittings inherit their grain structure from the pipe or plate they come from:

- Rolling and extrusion produce elongated grains along the pipe axis.

- Forming elbows and reducers can modify the grain orientation but often maintain a worked, refined structure.

- If the fitting includes a weld seam, there will be a weld metal region and a HAZ, each with different microstructures.

This structure typically offers good strength and toughness, but any seam or weld becomes a zone that must be carefully controlled.

Grain structure in forged fittings

Forged fittings undergo intense plastic deformation during forging:

- Grains are refined and compressed, reducing voids and discontinuities.

- Grain flow can be oriented to wrap around bends and changes in section thickness.

- The result is a dense, homogeneous metal with superior resistance to crack initiation and propagation.

Strength comparison (qualitative)

Both wrought and forged fittings can meet or exceed the minimum mechanical properties required by their standards. However, forged fittings usually provide:

- Slightly higher yield and tensile strength for the same material grade.

- More consistent properties throughout the fitting body.

- Better response to impact loading and vibration.

Fatigue resistance and vibration

Under cyclic pressure or mechanical vibration, defects such as weld flaws, inclusions, or porosity become critical. Here:

- Wrought fittings with good weld quality can perform very well.

- Forged fittings, with solid sections and directional grain flow, often have an edge in fatigue resistance, especially in small-bore, high-pressure connections.

Leak Integrity: Welded Joints vs Solid Bodies

Leak integrity isn’t just about metal strength—it’s about where leak paths can form.

Leak paths in wrought fittings

For wrought butt-weld fittings, the main potential leak paths are:

- The butt weld between fitting and pipe (root defects, lack of fusion, porosity).

- Any longitudinal seam weld in the fitting itself.

- Localized thinning or misalignment at the weld joint.

Leak integrity therefore depends heavily on:

- Welding procedure qualification (WPS/PQR).

- Welder skill and training

- Non-destructive testing (RT, UT, PT, MT) and acceptance criteria.

When executed correctly, butt-weld joints can be extremely leak-tight, with a smooth internal bore that minimizes turbulence and erosion.

Leak paths in forged fittings

For forged socket-weld or threaded fittings, potential leak paths include:

- Socket welds, where lack of penetration, incorrect gap, or poor root fusion can create crevices or cracks.

- Threaded joints, which depend on thread quality and sealant (tape, dope). Improper installation may leave micro-leak paths.

- Crevice corrosion in narrow gaps, especially in aggressive media.

Forged bodies themselves rarely leak through the metal; the risk is mainly at the connection interface.

Butt-weld vs socket-weld vs threaded leak performance

Butt-weld joints (wrought fittings):

- Excellent for high temperature and high pressure.

- Smooth bore; good for high flow and erosion control.

- Heavily dependent on weld quality but easy to inspect via RT/UT.

Socket-weld joints (forged fittings):

- Especially suitable for high-pressure service in small-bore piping systems. Short welds in cramped spaces are harder to inspect.

- Risk of lack of gap or misalignment if procedures are not followed.

Threaded joints (forged fittings):

- Simple and fast for small sizes.

- Higher leakage risk; not recommended for high vibration, high temperature, or lethal fluids.

Pressure, Temperature, and Service Conditions

Pressure ratings

- Wrought butt-weld fittings can be used across a wide range of pressure classes (e.g., systems designed to ASME pressure-temperature ratings for flanges and piping).

- Forged fittings often come in specific pressure classes such as Class 3000, 6000, and 9000 for socket and threaded connections.

In small-bore high-pressure applications, forged fittings are often the default choice, while larger sizes use wrought butt-weld fittings.

Temperature and creep

For high-temperature and creep-sensitive service (e.g., superheated steam):

- Butt-welded wrought fittings allow for a continuous weld and smooth bore, which is preferred in many codes and industry practices.

- Socket-weld and threaded joints are usually limited or prohibited for high temperatures, especially in critical service.

Media and hazard level

The type of fluid in the line also drives the choice:

- Flammable, toxic, or environmentally hazardous media → strong preference for fully welded systems (butt-weld wrought fittings) or solid forged fittings with high-integrity welds.

- Non-hazardous utilities like air, nitrogen, cooling water → both wrought and forged may be acceptable, depending on pressure and pipe size.

Standards, Codes, and Inspection Requirements

Key piping codes

Important design codes like ASME B31.1 (Power Piping) and ASME B31.3 (Process Piping) provide rules and guidance for:

- When butt-weld fittings should be used.

- When socket-weld or threaded fittings are allowed or restricted.

- Minimum examination requirements for welds and joints.

NDT requirements

Wrought butt-weld fittings:

- Butt welds often subject to radiographic (RT) or ultrasonic (UT) testing, especially in high-risk lines.

- Any seams in the fitting may also be examined.

Forged fittings:

- Body may be spot-checked using UT for internal defects.

- Socket welds are more often checked by surface methods (PT/MT) and visual inspection.

Hydrostatic tests

Both wrought and forged fittings, when supplied from reputable manufacturers, are usually hydrostatically tested or produced in accordance with standards that guarantee pressure performance when installed correctly.

Installation, Fabrication, and Maintenance Considerations

Welding skill and accessibility

- Butt-welds on wrought fittings require proper fit-up, root gap, and full penetration welding.

- Socket-welds on forged fittings need correct socket gap and careful control to avoid over-welding and creating stress risers.

In very tight pipe racks or skids, small forged fittings may be easier to install than full butt-weld joints.

Space and layout

- Wrought butt-weld elbows, especially long-radius, are ideal for smooth flow and gradual direction changes, but take more physical space.

- Forged fittings are very compact, making them attractive in tight spaces, close manifolds, or instrument hook-ups.

Inspection and repair

- Butt-welds are easier to examine with RT/UT and provide a clear inspection record.

- Socket welds and threaded fittings are harder to inspect internally; leak testing and visual examination become more important.

- Replacing a forged fitting in congested small-bore systems can be tedious; replacing a large wrought elbow can require cutting and re-welding multiple joints.

Cost vs Performance: Lifecycle View

Initial cost

- Material cost per kilogram can be similar, but forged fittings may be more expensive per piece due to forging and machining.

- Wrought butt-weld fittings may be relatively cheaper for larger diameters, but welding and NDT labor costs are significant.

Fabrication and labor

- Butt-welds: more welding time, more welding consumables, more NDT, higher skilled labor.

- Socket and threaded joints: less welding, simpler fabrication, but still require skilled fitters to ensure proper assembly.

Cost of leaks and failures

The true cost is not just material and labor but:

- Unplanned shutdowns

- Product loss or contamination

- Safety incidents and environmental cleanup

- Regulatory penalties and reputation damage

In high-risk services, spending more on higher integrity fittings—whether wrought butt-weld or forged—is usually justified.

Cost/risk comparison table

Table 2 – Typical Cost–Performance Trade-Offs

| Scenario | Preferred Fitting Type | Initial Cost Impact | Leak & Failure Risk |

| Large-bore, high-temperature steam | Wrought butt-weld | Higher weld/NDT cost | Low risk if welds are well executed |

| Small-bore, high-pressure process line | Forged socket-weld | Higher unit price | Very low if welding done correctly |

| Utility air or nitrogen, small diameter | Forged threaded/socket-weld | Lower fabrication cost | Moderate; depends on installation quality |

| Low-pressure cooling water, large bore | Wrought butt-weld | Moderate material + welding | Low; consequence of leaks generally manageable |

Application Scenarios: Which Choice Is Better?

When wrought fittings are usually preferred

Wrought butt-weld fittings are often the first choice when:

- Pipe size is medium to large (e.g., DN 50 and above).

- Service is high temperature or high energy (e.g., main steam lines).

- A fully welded, smooth-bore system is required for flow efficiency and cleanliness.

- Codes or clients specify no socket-weld or threaded joints in certain categories of service.

When forged fittings are usually preferred

Forged fittings are typically chosen when:

- Pipe size is small-bore (e.g., DN 50 and below).

- Service pressure is high, demanding compact and strong connectors.

- The system includes instrumentation, drains, vents, sample lines, manifolds, and other small-bore attachments.

- Space is limited, such as on skids or near equipment nozzles.

Case-style examples

Example 1: 2″ high-pressure hydrocarbon branch

A forged socket-weld tee and elbows provide robust strength and leak integrity in a small, confined space where butt-weld access is difficult.

Example 2: 16″ refinery process line

Wrought butt-weld elbows, tees, and reducers offer excellent flow characteristics and structural integrity, with welds fully inspected by RT/UT.