S31803 Duplex Stainless Steel Pipe Fittings

- Superior Weldability: Surpasses ferritic and austenitic stainless steels, offering better resistance to thermal cracking.

- Corrosion Resistance: Highly resistant to stress corrosion cracking and pitting, even in harsh environments.

- Durability: Long-lasting performance under extreme conditions, including high temperatures and stress.

- Versatile Applications: Suitable for oil & gas pipelines, seawater treatment, petrochemical industries, and more.

Technical Specifications

| Specification | Details |

| Size Range | 2″-24″ |

| Wall Thickness | Sch10s-Schxxs |

| Materials | ASTM A815 UNS S31803/S32205/S32750/S32760 |

| Manufacturing Standards | ASME B16.9, ASME B16.28, JISB2311, DIN 2605, DIN 2606 |

| End Types | Bevel ends, Plain ends |

| Testing Methods | Magnetic particle test, Penetration test, Ultrasonic test, Radiographic test |

| Surface Treatment | Sand blasted, Ball blasted, Antitrust varnish |

| Delivery Time | 20-35 days |

| Supply Capacity | 60-80 Tons/month |

Applications

- Petrochemical Equipment: Ideal for use in petrochemical plants and piping systems.

- Seawater & Wastewater Treatment: Corrosion-resistant in harsh environmental conditions.

- Oil & Gas Pipelines: Durable in high-pressure and high-temperature pipeline systems.

- Paper-Making Machinery: Reliable performance in high-stress environments.

- Marine & Shipbuilding: Used in marine structures for enhanced resistance to saltwater corrosion.

Production Process

Our precision casting production process integrates wax modeling, automated shell making, controlled pouring, heat treatment, and machining to ensure dimensional accuracy, integrity, and quality.

Wax Injection

Shell Making

Shell Baking

Pouring

Shot Blasting

Heat Treatment

Machining

Inspection

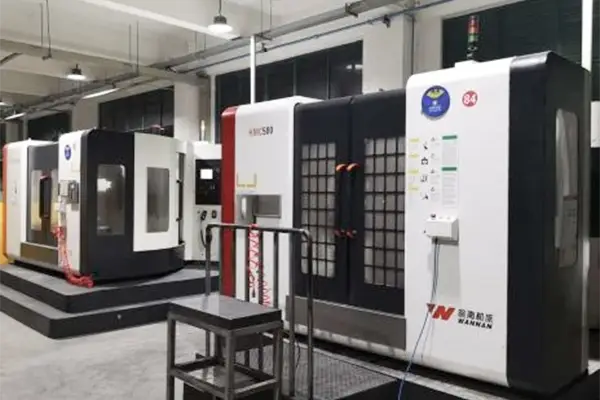

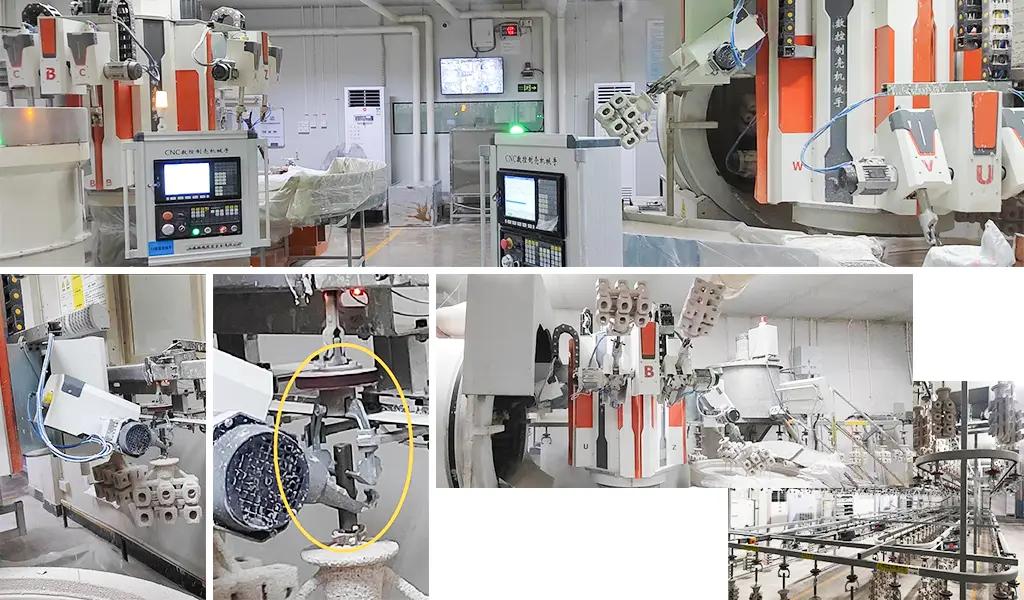

Advanced Workshop

Advanced workshops include wax model production, CNC robotic shell making, semi-automatic pouring, baking furnaces, and machining centers supporting automation, efficiency, flexibility, and operations.

Medium Temperature Wax Workshop

Low Temperature Wax Workshop

9-axles CNC Shell-making Robot Arm Workshop

Semi-auto Pouring Machine

Baking Furnace

Horizontal CNC Machining Center

New Shell Making Automation Line

New shell making automation line optimizes reduction processes, improves production efficiency, ensures reliable equipment operation, extends running time, and significantly reduces labor intensity overall.

Shell Making Automation Line No. 01 – Small & Medium Parts

Automated shell making line for small and medium castings improves shell uniformity, reduces manual intervention, and enhances production stability and efficiency.

Shell Making Automation Line No. 02 – Large Parts

Specialized automation line supports large investment castings, handling complex geometries and higher weights while maintaining shell strength and process reliability.

Shell Making Automation Line No. 03 – Investment Casting

Optimized shell making system streamlines reduction processes, improves efficiency, ensures long-term equipment reliability, and significantly reduces labor intensity.

Quality Inspection

Comprehensive quality inspection system covering materials, processes, dimensions, and final products to ensure traceability, consistency, and full compliance with customer specifications.

Zeiss CMM Machine

X-ray Flaw Detector

100T Horizontal Tensile Testing Machine

Rockwell Hardness Standard Machine

Logistics & Delivery

Monthly Capacity: 500–1000 tons.

Packing: Wooden crates, steel frames, or per client request.

Shipment: By Sea (recommended, saves cost for forging parts) / By Air (fast but expensive).

Payment Terms: 30% deposit with balance via B/L copy; or 100% L/C at sight.

Delivery Terms: FOB, CIF, CNF.