About Boberry

Company Profile

- Boberry is a family-owned enterprise, formerly known as JIACHANG AUTOMOBILE ELECTRIC COMPANY, founded in 1983. With 30+ years of development, we focus on casting, forging, flange, and machining fields, serving industries such as metallurgy, energy, chemical, and shipbuilding.

- Our group includes Boberry Material Co., Ltd., Boberry Mechanical Technology GMBH, and others. We maintain strict quality systems, advanced testing equipment, and a skilled team of over 60 senior engineers. Certifications include ISO9001 and TUV.

- As a leading machinery parts supplier, we meet customer demands for high-precision, complex parts by importing advanced equipment and offering design optimization and assembly services—ensuring stable quality and excellent value worldwide.

The Optimal Solution

Integrated Production Line

Professional Technical Support

Strong After-sales Service

Advanced Processing Equipment

Equipped with multiple hydraulic presses, electro-hydraulic hammers, and a D53K-6300 ring roll mill, capable of producing 5kg–60T forgings with precision heat treatment for various high-demand industries.

Our three casting lines, which have an annual capacity of 3000 tons, are equipped with modern heat treatment for accuracy and dependability, suspension conveyors, sealing wax treatment systems, and vacuum induction furnaces.

We are equipped with four-shaft machining centers, CNC vertical lathes, gantry boring-milling machines, and advanced centers to ensure high-precision forging and casting with excellent accuracy and surface finish.

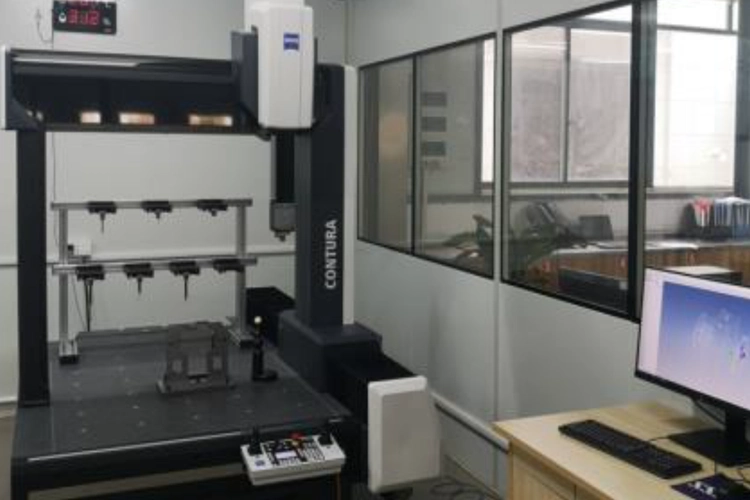

Testing & Inspection Equipment

With the use of spectrometers, hardness testers, CMMs, defect detectors, and microscopes, we can guarantee 100% product quality through non-destructive evaluation, mechanical testing, chemical analysis, and dimensional inspection.

Cooperate with Us

- Boberry has introduced advanced processing and inspection equipment, trained workers regularly, and supported engineers in continued learning. Our product accuracy now meets global standards, serving needs for high-precision and complex parts.

- We provide and improve process solutions based on customer designs and offer reliable assembly services. Our products combine stable quality, competitive prices, and performance that exceeds expectations.

- We warmly welcome global partners to visit us for inspection and cooperation. Let’s work together to find the best solutions in the machinery industry.

cONTACT US NOW